Textile printing and dyeing wastewater treatment device and technology

A technology for wastewater treatment, textile printing and dyeing, applied in the fields of environmental protection and water treatment, can solve the problems of oxygen consumption, affecting the effect of wastewater treatment, complex design structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

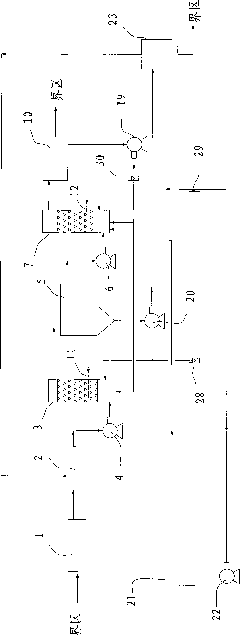

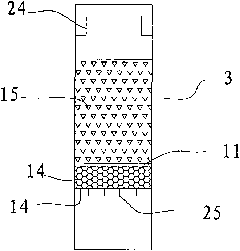

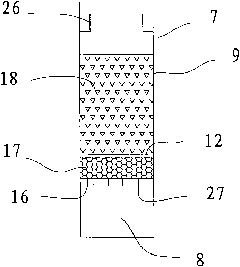

[0022] refer to figure 1 , 2And 3, a textile printing and dyeing wastewater treatment device, comprising a grid 1 connected in sequence, a regulating buffer tank 2, a first water inlet pump 4, a biological peristaltic bed 3, a sedimentation buffer tank 5, a second water inlet pump 6, an ozone-exposure Gas biofilter 7, clean water pool 10, wherein the inlet pipeline of the first water inlet pump 4 is connected to the adjustment buffer tank 2, and the outlet pipeline is connected to the water inlet at the bottom of the biological peristaltic bed 3, and the biological peristaltic bed 3 is provided with a filter plate 13, on which A cobblestone cushion 14 and a biological ceramsite layer 15 are provided from bottom to top, a first aeration pipe 11 is provided at 100-200 mm above the filter plate 13, a long handle filter head 25 is provided on the filter plate 13, and the biological peristaltic bed 3 The top is provided with a pipeline connected to the outlet weir 24 of the sedime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com