Membrane with a stable nanosized microstructure and method for producing same

A nano-scale, micro-structured technology, used in oxygen preparation, separation methods, chemical instruments and methods, etc., can solve the problems of short membrane life, chemical instability, and unsuitable membrane mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

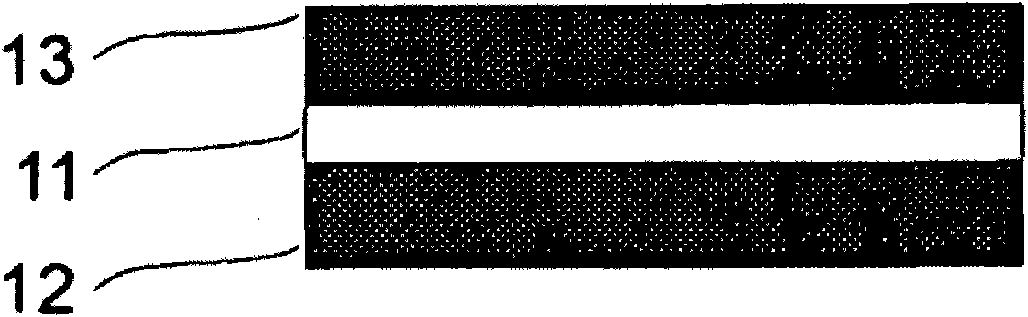

[0088] A symmetrical flat membrane with an impregnated catalyst layer is obtained. structured as figure 1 shown.

[0089] The first step involves tape casting the first and second catalyst layers and the membrane layer.

[0090] Suspensions for tape casting were prepared by ball milling powders with polyvinylpyrrolidone (PVP), polyvinyl butyral (PVB) and EtOH+MEK as additives. After particle size control, the suspension was cast with a double doctor blade system and the cast tape was subsequently dried.

[0091] Catalyst precursor layer (layers 12 and 13): The suspension contains Fe22Cr. The raw thickness (greenthickness) is in the range of 50-70 μm. The sintered porosity of the layer is about 50%, and the pore diameter is in the range of 1-2 μm.

[0092] Membrane layer (layer 11): the suspension contains Ce 0.9 Gd 0.1 o 2-δ (CGO10) powder and 1vol% Cr 2 o 3 . The raw thickness of the foil is approximately 25 μm. The sintered density of the layer is greater than 96...

Embodiment 2

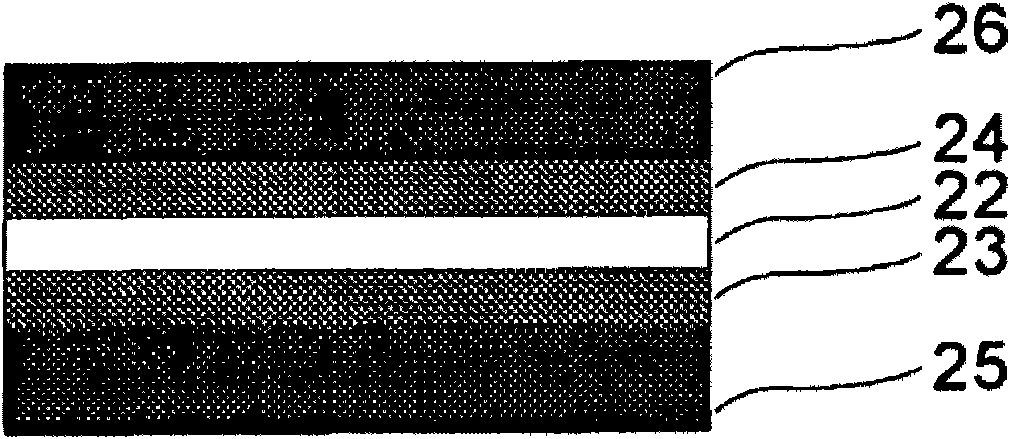

[0100] The film was obtained as described in Example 1, except that there was an intermediate layer comprising metal and some cerium oxide to ensure better adhesion between the film and the metal layer. Its structure is in figure 2 shown in .

[0101] The first step involves tape casting the metal-containing layers (25 and 26), the intermediate layers (23 and 24) and the film layer (22).

[0102] Suspensions for tape casting were prepared and shaped as described in Example 1.

[0103] Metal support layers (25 and 26): The suspension contains Fe22Cr. The unprocessed thickness is in the range of 50 to 70 μm. The sintered porosity of the layer is about 50%, and the pore diameter is in the range of 3-4 μm.

[0104] Middle catalyst precursor layer (23 and 24): The suspension contained 90 vol% Fe22Cr and 10 vol% CGO10. The raw thickness is in the range of 25 μm. The sintered porosity of the layer is about 50%, and the pore diameter is in the range of 1-2 μm.

[0105]Film lay...

Embodiment 3

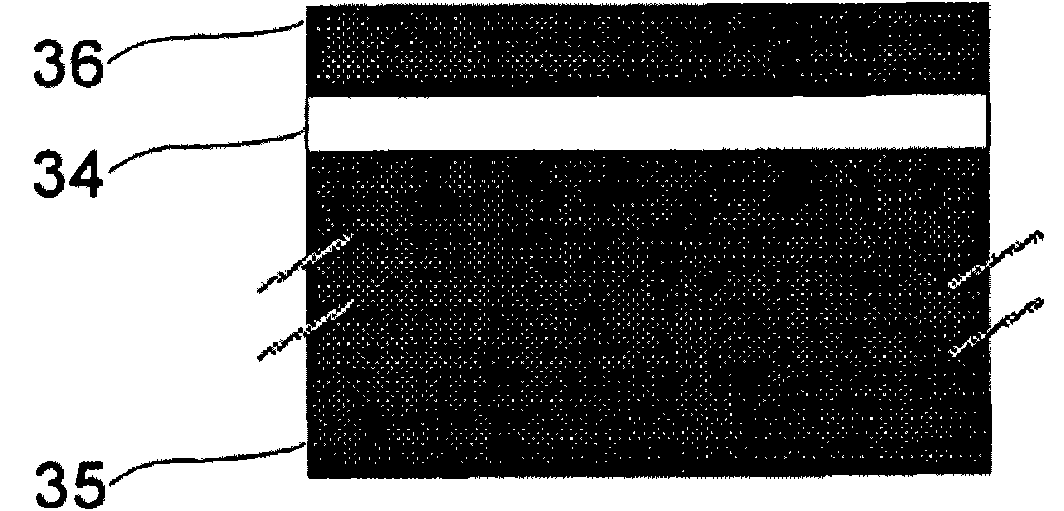

[0112] Membranes were obtained as described in Example 1, except that there was a thick support layer, ie an asymmetric membrane structure. Its structure is in image 3 shown in .

[0113] The first step involved tape casting two different metal-containing layers (~40 μm and 400 μm, respectively), and a film layer.

[0114] Suspensions for tape casting were prepared and shaped as described in Example 1.

[0115] Metal Support Layer and Catalyst Precursor Layer (Layer 35): The suspension contained 95 vol% Fe22Cr and 5 vol% CGO10. The raw thickness is in the range of 400 μm. The sintered porosity of the layer is about 50%, and the pore size is in the range of 4 μm.

[0116] Catalyst precursor layer (layer 36): The suspension contained 95 vol% Fe22Cr and 5 vol% CGO10. The raw thickness is in the range of 40 μm. The sintered porosity of the layer is about 40%, and the pore size is in the range of 3 μm.

[0117] Layer 3 (membrane layer - layer 34): the suspension contains CG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com