Method for preparing nano titanium dioxide heterogeneous composite membrane

A nano-titanium dioxide, titanium dioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of uneven film layer, low substrate connection strength, and separation of charges. high recombination rate

Inactive Publication Date: 2010-08-04

TAIYUAN UNIV OF TECH

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Titanium dioxide is a white pigment with the advantages of non-toxicity, stable chemical properties, and low price. However, due to the high cost of ultraviolet light sources, the large-scale application of titanium dioxide in the field of environmental purification technology is limited. Due to the high recombination rate of separated charges, Also affects quantum yield issues

There are many methods for the preparation of titanium dioxide composite films, such as chemical vapor deposition, coating drying, etc., but these methods have some disadvantages and deficiencies, some of which are complex, and the product purity is low; Substrate connection strength is low, easy to fall off, and chemical and physical properties are unstable, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

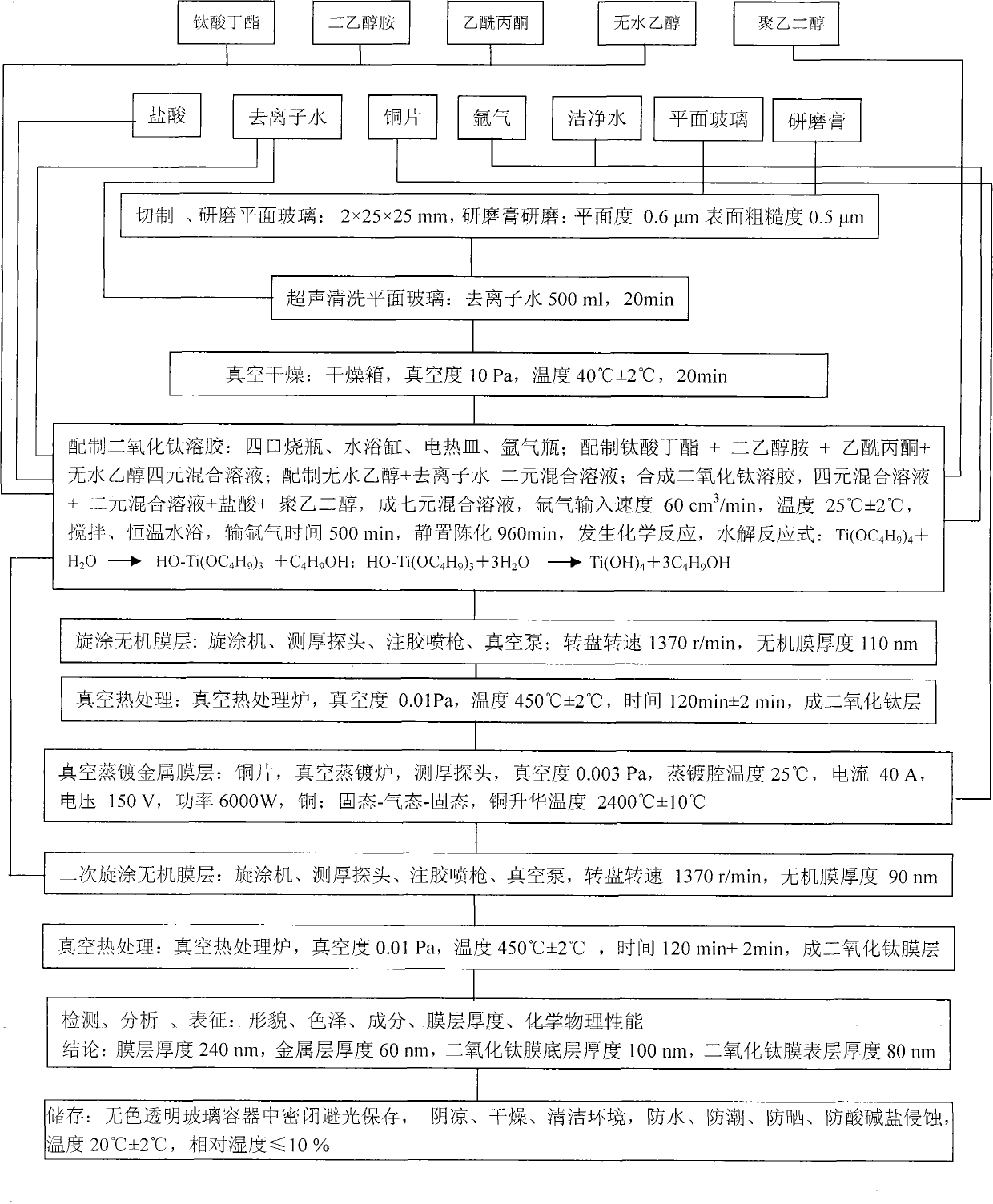

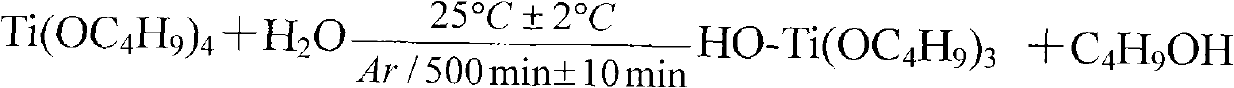

The invention relates to a method for preparing a nano titanium dioxide heterogeneous composite membrane. In the invention, strict process flow is adopted, and precision and purity of chemical materials are controlled. The method comprises the following steps: cutting, grinding, cleaning and drying flat glass; preparing titanium dioxide seven-element mixed sol; performing spin coating on titanium dioxide inorganic membrane in a layered manner; and carrying out vacuum evaporation of metallic copper membrane layer and vacuum heat treatment to obtain the nano titanium dioxide heterogeneous composite membrane, wherein the thicknesses of inorganic titanium dioxide membrane layer are 100nm and 80nm, the thickness of metallic copper membrane layer is 60nm, and the thickness of the total membrane layer is 240nm. The product prepared by the invention has the advantages of advanced technology, reasonable and strict membrane structure, high purity, and good photochemical catalysis performance under the sun. The membrane purity is up to 99.5%. The method is an ideal method for preparing nano titanium dioxide heterogeneous composite membrane.

Description

technical field The invention relates to a method for preparing a nano-titanium dioxide heterogeneous composite film, which belongs to the technical field of photocatalytic film preparation methods for inorganic semiconductor materials. Background technique Titanium dioxide is an inorganic semiconductor material with a wide band gap. The theoretical band gap is 3.2eV. Under ultraviolet light, electrons in the valence band of titanium dioxide can be excited to the conduction band to form separated electron-hole pairs. With strong oxidation and reduction ability, it can undergo oxidation and reduction reactions with organic pollutants, so as to achieve the purpose of degrading organic pollutants. Titanium dioxide is a white pigment with the advantages of non-toxicity, stable chemical properties, and low price. However, due to the high cost of ultraviolet light sources, the large-scale application of titanium dioxide in the field of environmental purification technology is lim...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C17/36B01J23/72B01J21/06

Inventor 梁伟白爱英郭玉玲王红霞

Owner TAIYUAN UNIV OF TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com