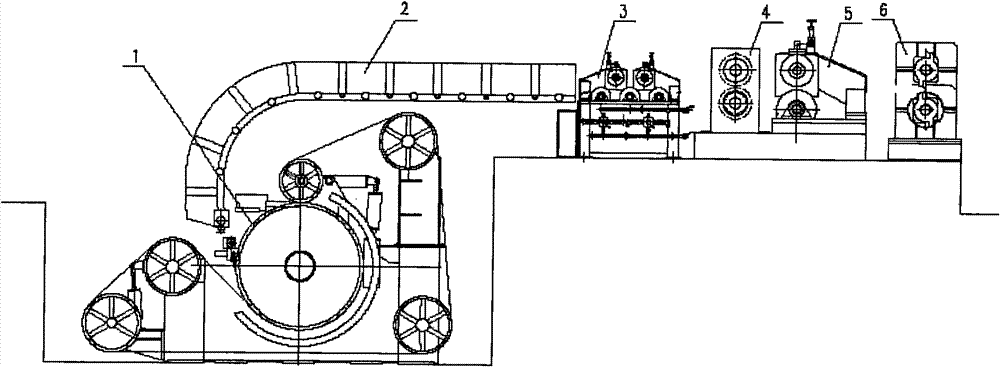

Method and device for producing A356 aluminum alloy by belt casting

A casting production, aluminum alloy technology, applied in the field of A356 aluminum alloy production by wheel-type continuous casting, can solve the problems of high technical requirements and production costs, large potential safety hazards in the working environment, poor quality stability, etc., to achieve rapid product variety, production Low cost and low component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

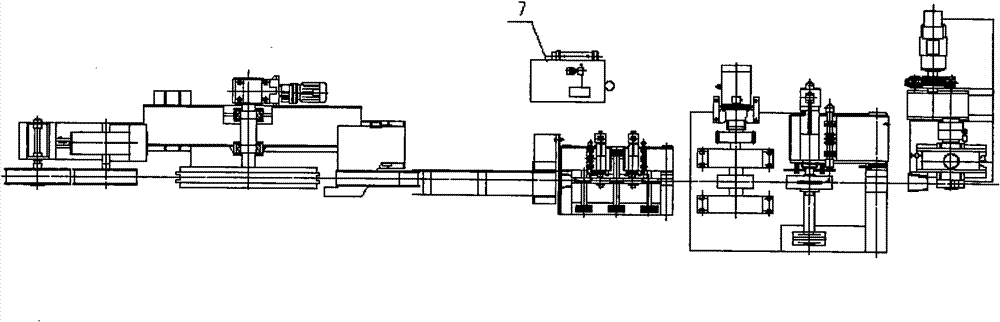

Method used

Image

Examples

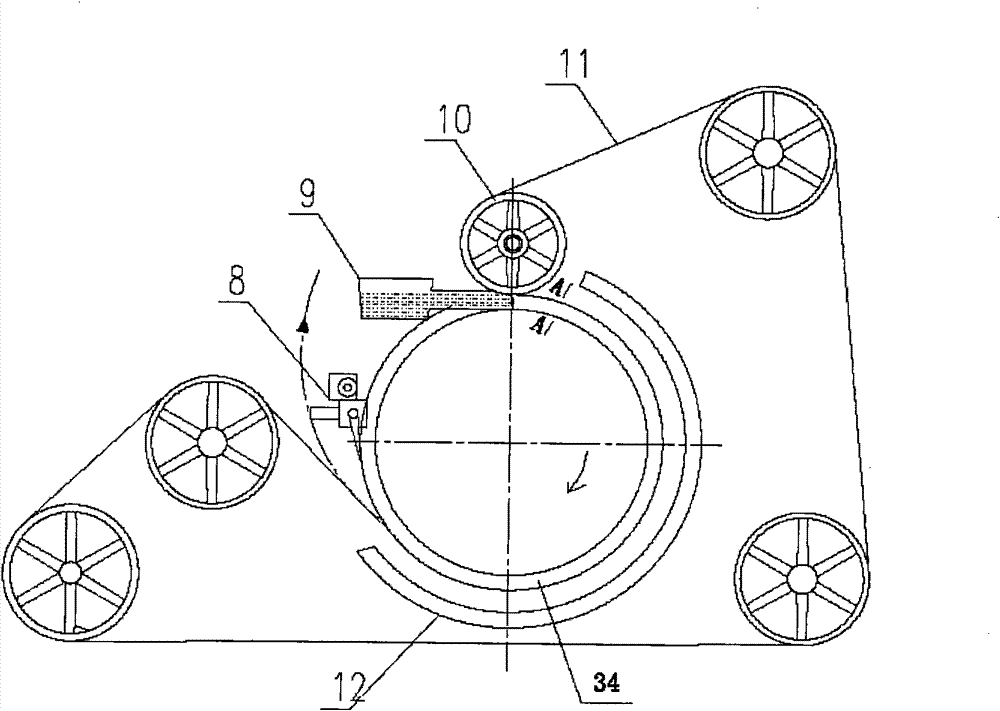

Embodiment Construction

[0028] Add electrolytic aluminum liquid, aluminum ingot or production waste and metal silicon, high-purity magnesium ingot, aluminum-strontium alloy, titanium agent, etc. into the smelting furnace, of which electrolytic aluminum liquid is 87.76%, production waste is 4.58%, metal silicon is 6.75%, high-purity magnesium 0.36% for ingot, 0.42% for aluminum-strontium alloy, and 0.13% for titanium agent. After the chemical composition test meets the requirements of A356 aluminum alloy, high-purity nitrogen gas (purity above 99.999%) is introduced, and 1.2% of the total amount of aluminum liquid is added. The refining agent is refined, and the refining temperature is controlled at 750-760°C, and then it enters a static furnace for standing, after being degassed by online nitrogen (purity is above 99.999%) and filtered by a ceramic filter plate (the above are all prior art), and then continuously Pour into the casting machine and continuously pass cooling water around the crystallizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com