Superplastic forming and processing method for sheets and superplastic-forming air pressure loading device thereof

A technology of superplastic forming and processing method, applied in the field of superplastic forming air pressure loading device, can solve the problem of strain rate deviating from the optimal range, etc., and achieve the effect of improving wall thickness distribution and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the described scope of implementation.

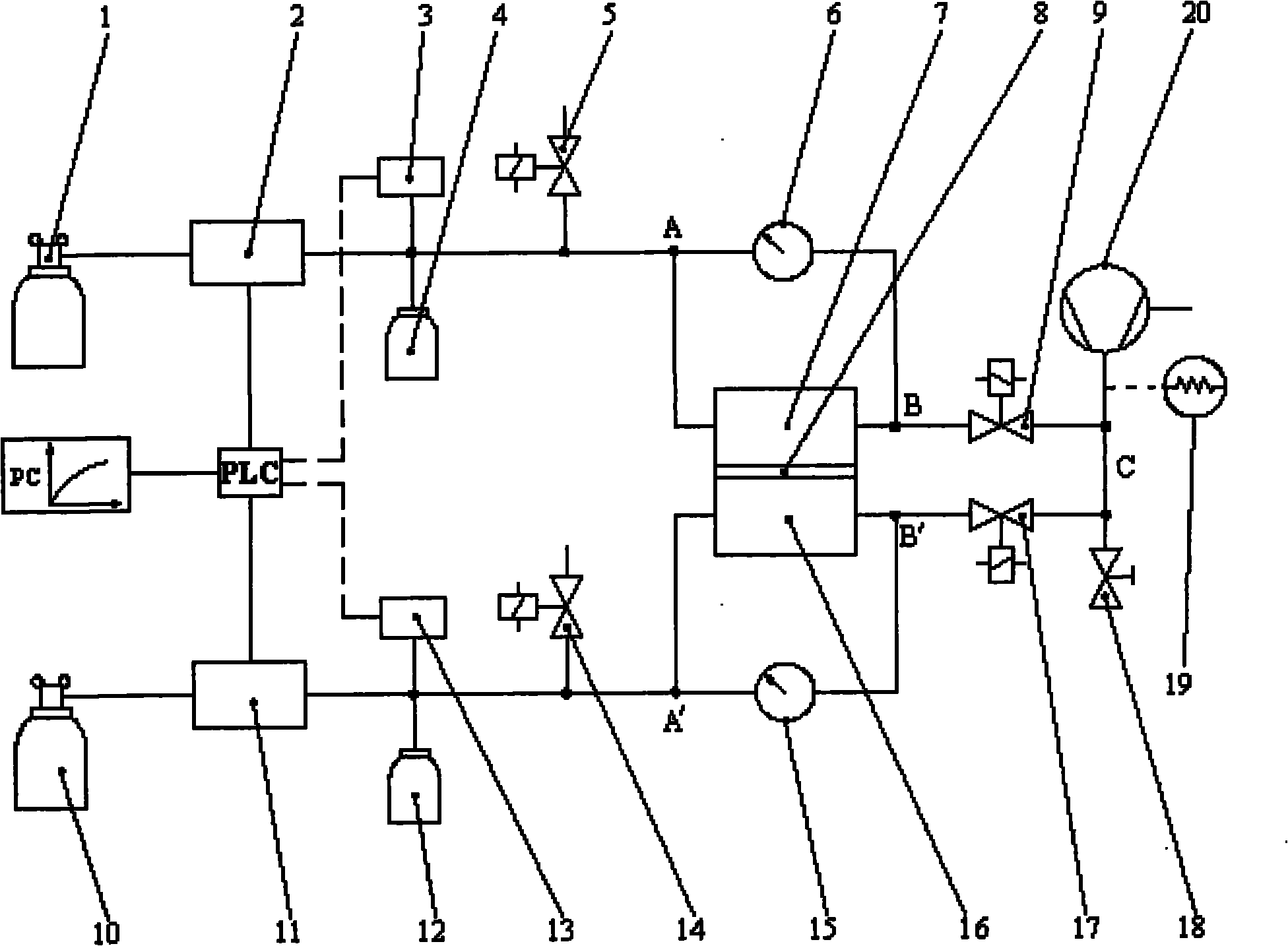

[0020] figure 1 It is a schematic diagram of a superplastic forming air pressure loading device used in a sheet material superplastic forming processing method of the present invention, including a control system, an upper mold air pressure loading system, a lower mold air pressure loading system, and an upper and lower mold vacuum system. The system is composed of industrial PC and PLC. PLC is an industrial computer. The industrial PC issues a dynamic pressure p command according to the pressure p-time t curve. The PLC executes the command and controls the upper mold air pressure loading system, the lower mold air pressure loading system and the upper and lower mold pumping. On and off of the vacuum system. The upper mold air pressure loading system is connected to the upper mold inlet port A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com