Blow molding apparatus and blow molding method

一种吹塑成型、预成型件的技术,应用在其他家里用具、家里用具、家用元件等方向,能够解决温度不均匀、预成型件温度不均、无法同时成型满足多个树脂容器等问题,达到温度状态优化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

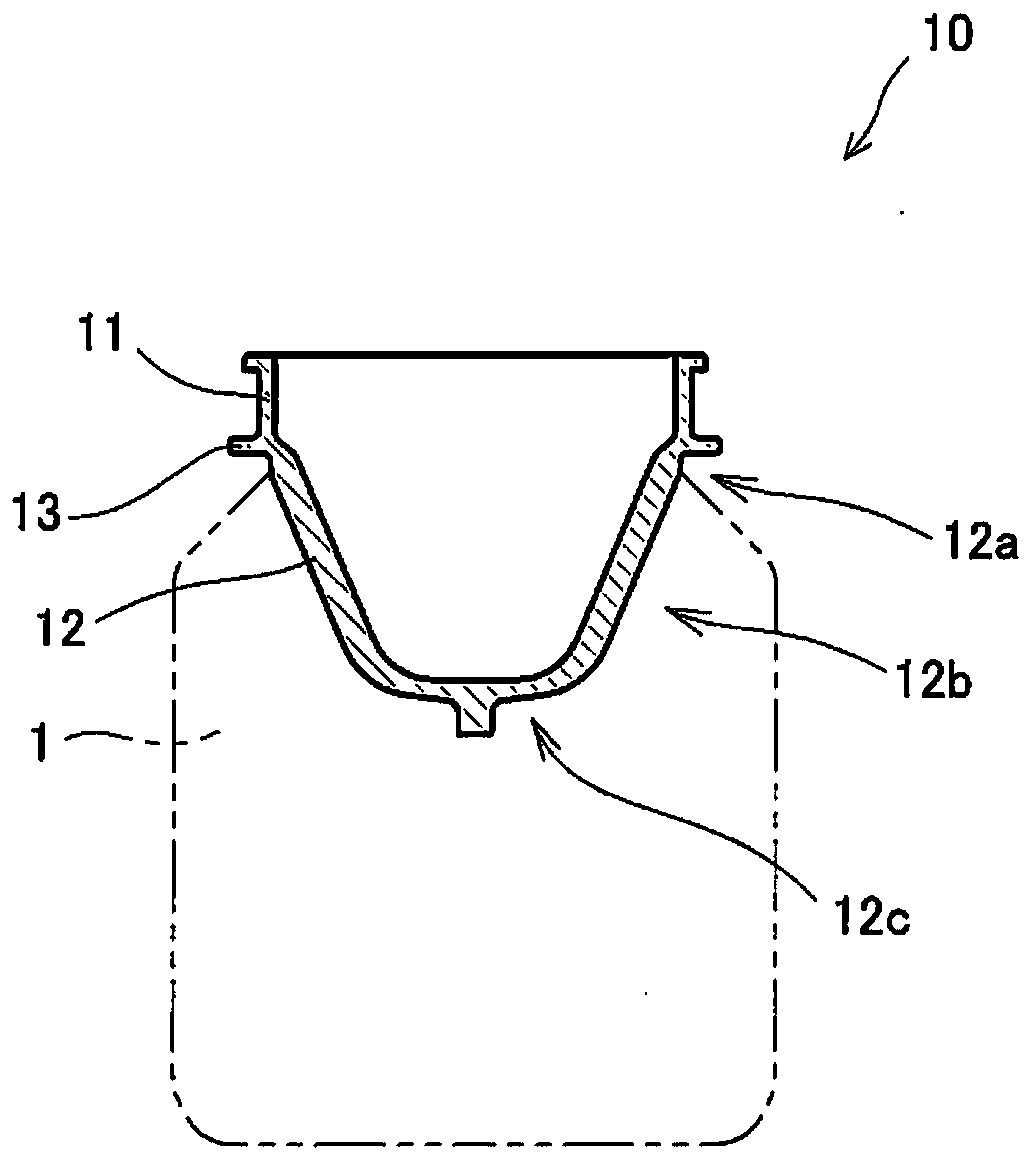

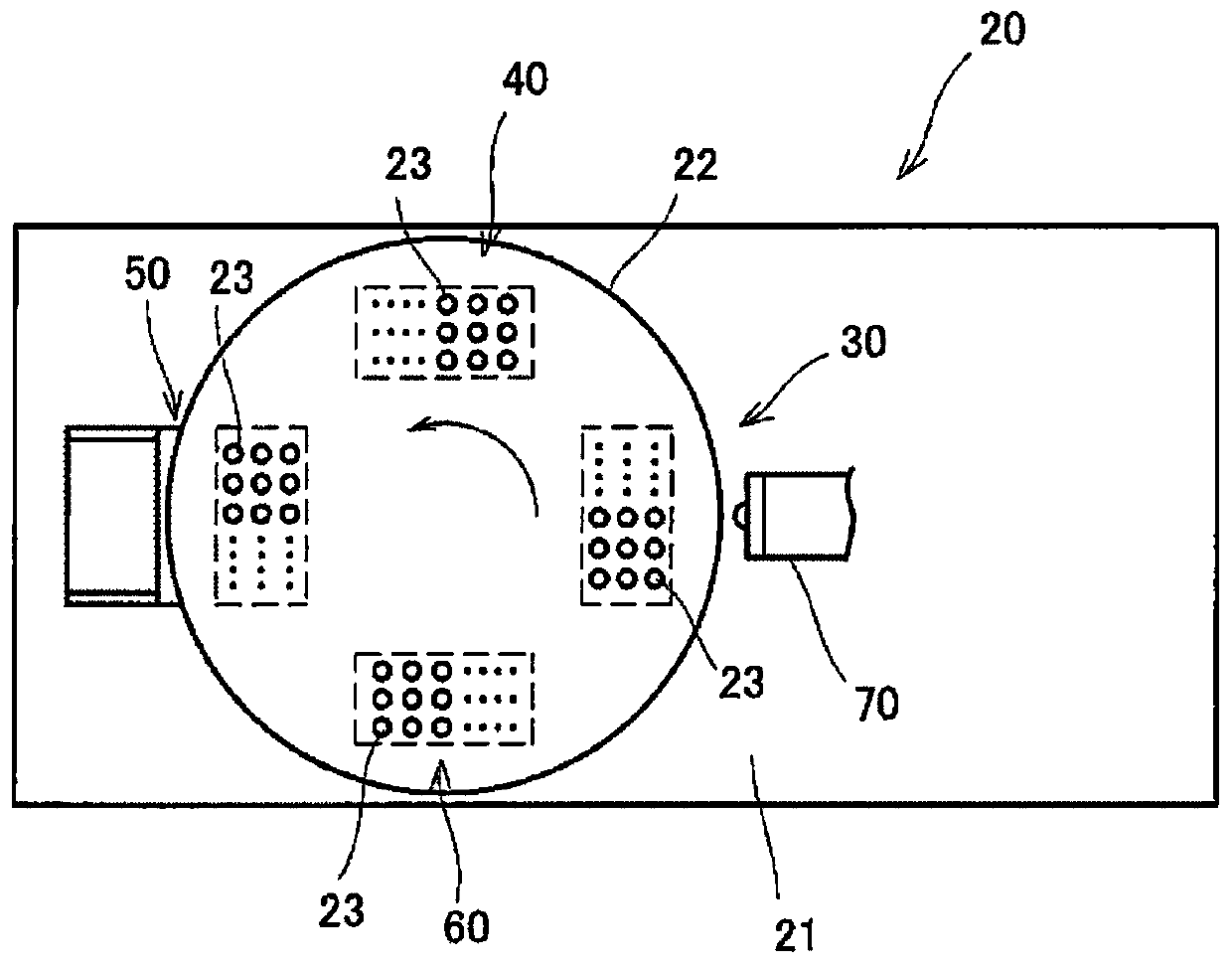

[0037] An embodiment of the present invention will be described in detail below with reference to the drawings.

[0038] First, an example of the shape of the resin container formed by the blow molding apparatus and the blow molding method of this embodiment will be described.

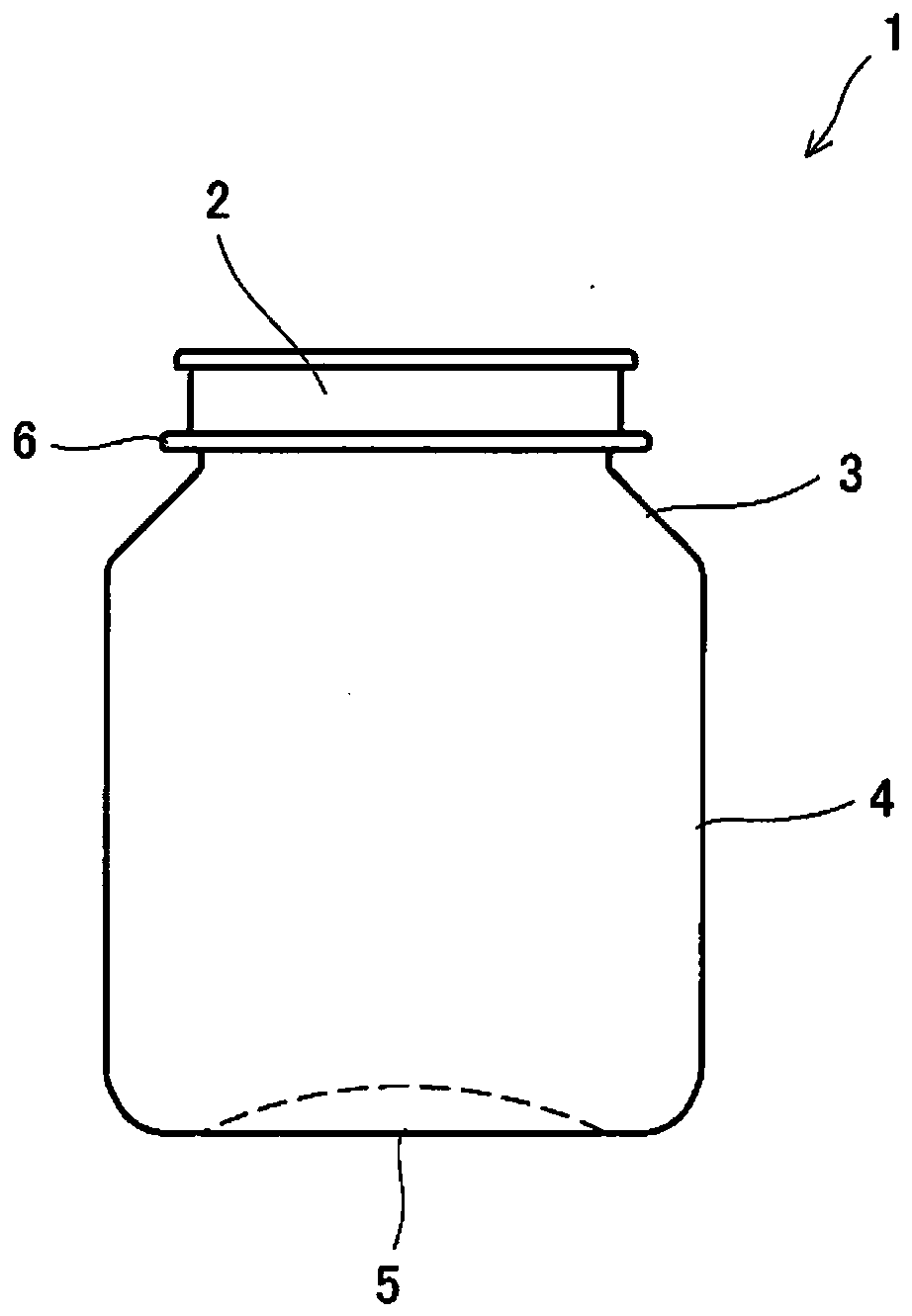

[0039] Such as figure 1 As shown, the resin container 1 is a small and lightweight container made of synthetic resin such as polyethylene terephthalate (PET), polypropylene (PP), polyethylene (PE), and used for storing beverages, for example. A resin container (small and lightweight container) 1 has a neck (mouth) 2 provided at the upper end, a substantially cylindrical main body 4 continuous from the neck 2 via a shoulder 3 , and a bottom closing the bottom of the main body 4 5. In addition, a support ring 6 is provided on the outer peripheral surface of the neck 2 in the vicinity of the boundary between the neck 2 and the shoulder 3 . In addition, the above-mentioned resin container 1 sets the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com