Parison forming device

A technology for forming molds and blanks, which is applied in the field of parison forming devices, can solve the problems of foreign matter being drawn in, and achieve the effect of improving airtightness and good wall thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

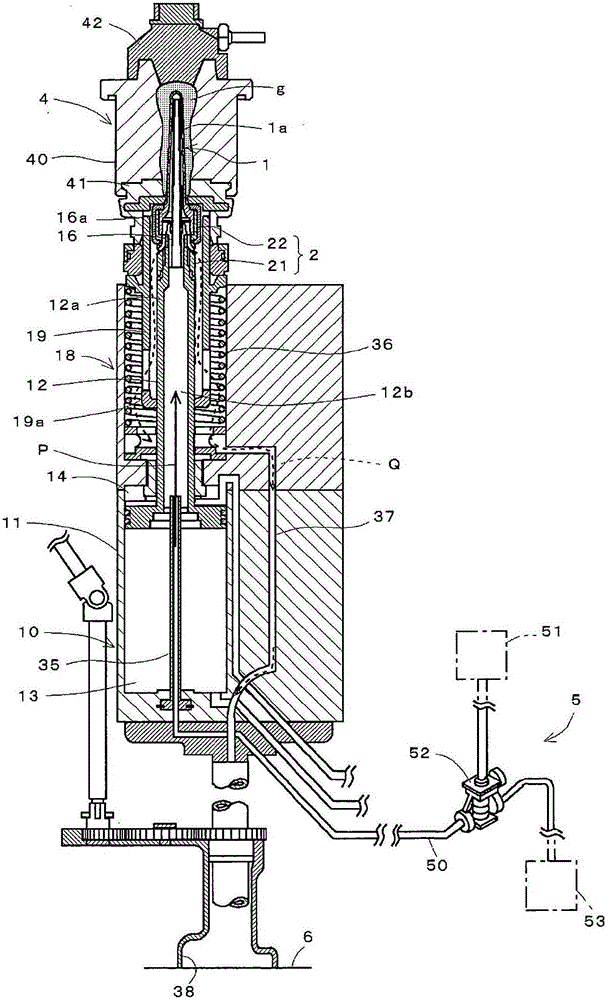

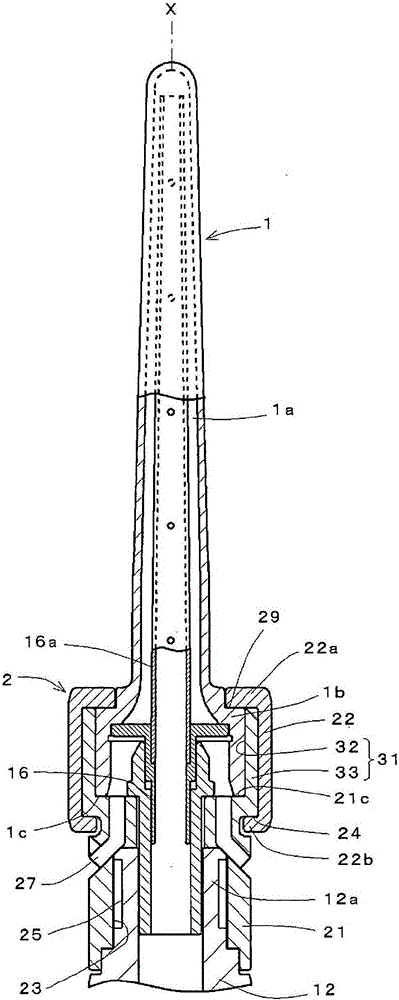

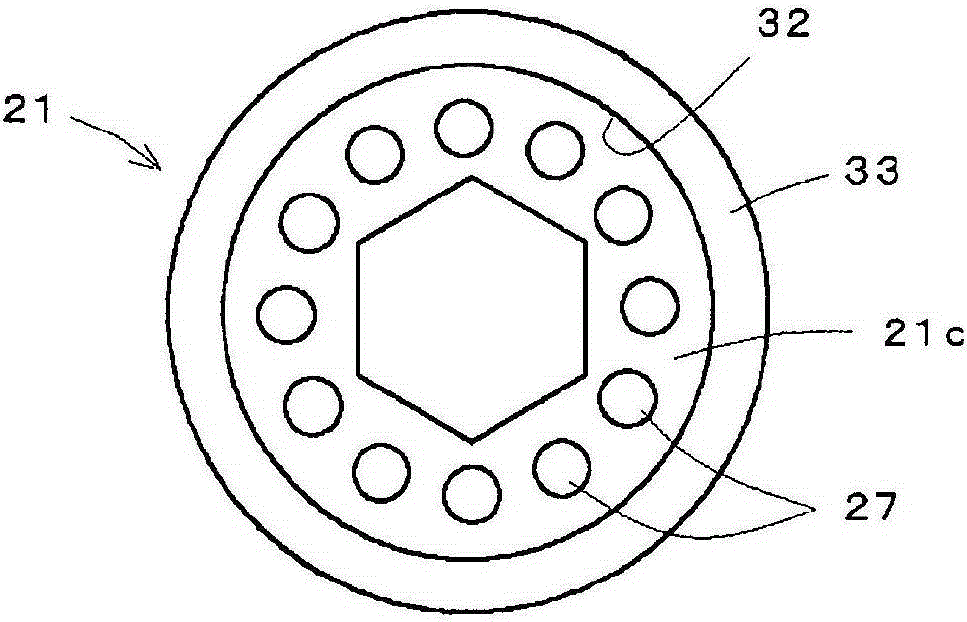

[0058] figure 1 The overall structure of the parison molding apparatus which is one Example of this invention is shown.

[0059] The parison forming device of this embodiment is used for forming a glass bottle whose overall wall thickness is thin, especially for forming a parison which is used to form an ultra-lightweight bottle whose lightness index is less than 0.7 and is called It is a glass bottle with carbonated beverage as the content of "gas-containing substance" (Japanese: ガス物). Here, the "lightness index" (referred to as "L value"; refer to the homepage of the Japan Glass Bottle Association) refers to the lightness index obtained by calculating the relationship between the capacity of the bottle and the mass of the bottle (the amount of glass used) using a function. The index of the measure. Specifically, the mass (g) of the bottle is divided by the power of 0.77 of the full capacity (ml) of the bottle, and then multiplied by a coefficient of 0.44 on this basis to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com