Method for processing surface of superhigh molecular weight polyethylene artificial cotyla

An ultra-high molecular weight, artificial joint technology, applied in the field of surface treatment of ultra-high molecular weight polyethylene artificial joints, can solve the problems of high-energy particle injection method, complex equipment, reinforced ultra-high molecular weight polyethylene, and high technical requirements for staff. The treatment effect is uniform, the process is simple, and the process is environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] A specific embodiment of the present invention is: a surface treatment method of ultra-high molecular weight polyethylene artificial joint socket, the specific steps of which are:

[0023] A. Put the ultra-high molecular weight polyethylene artificial joint socket into the vacuum chamber of the electron cyclotron resonance microwave plasma chemical vapor deposition device, and the vacuum chamber is evacuated to 2×10 -3 Pa;

[0024] B. Introduce oxygen into the vacuum chamber until the pressure is 2Pa;

[0025] C. Set the microwave source power of the deposition device to 400W, turn on the microwave power supply, perform gas discharge, and form plasma; at the same time, turn on the bias power supply of the deposition device, and carry out surface treatment on the artificial joint socket for 10 minutes, and the bias power supply during processing The frequency is 15kHZ, the duty cycle is 10%, and the amplitude is -300V.

[0026] The artificial joint socket obtained afte...

Embodiment 2

[0035] The method of this example is basically the same as that of Example 1, except that in the B step, the vacuum chamber is filled with argon.

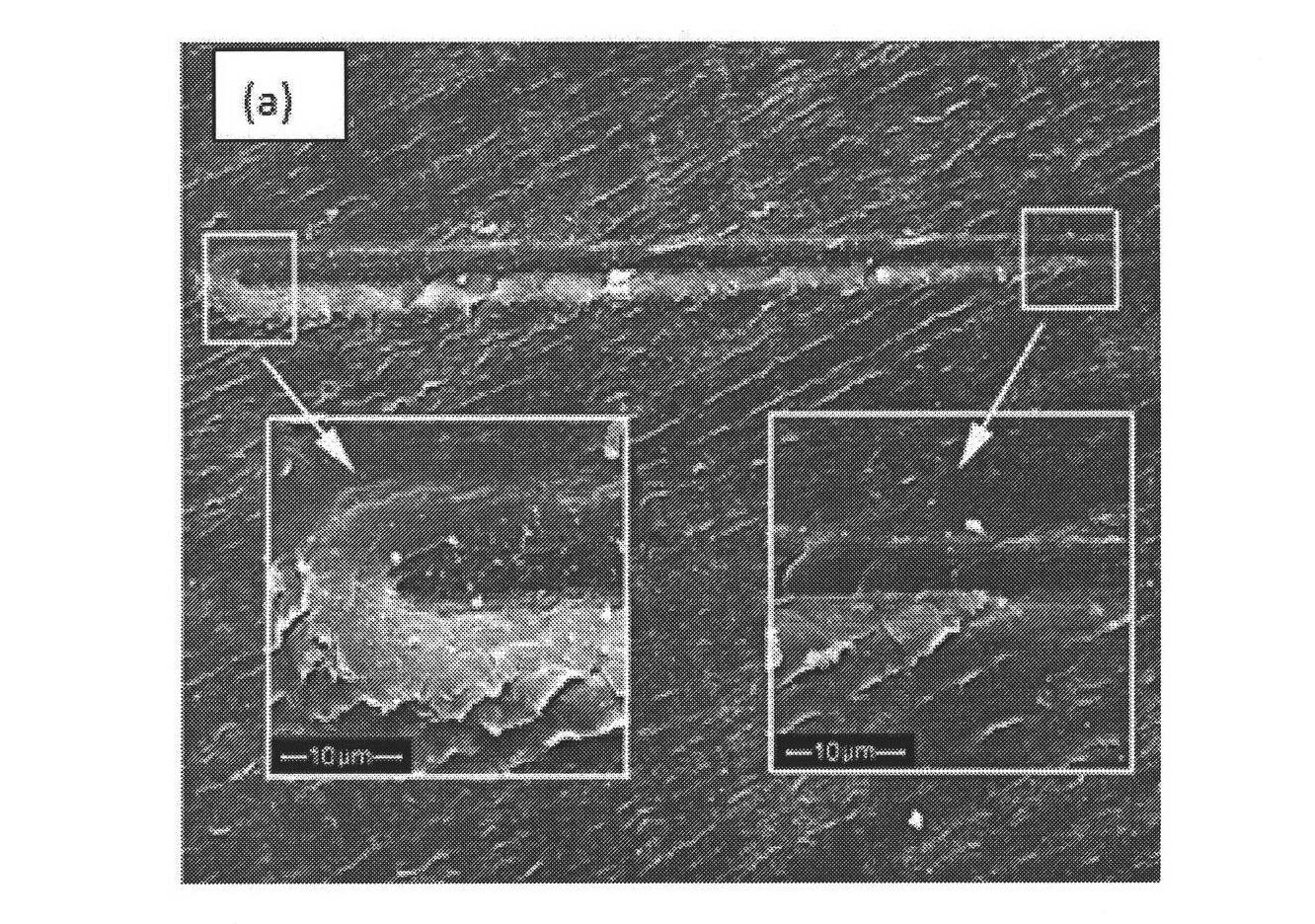

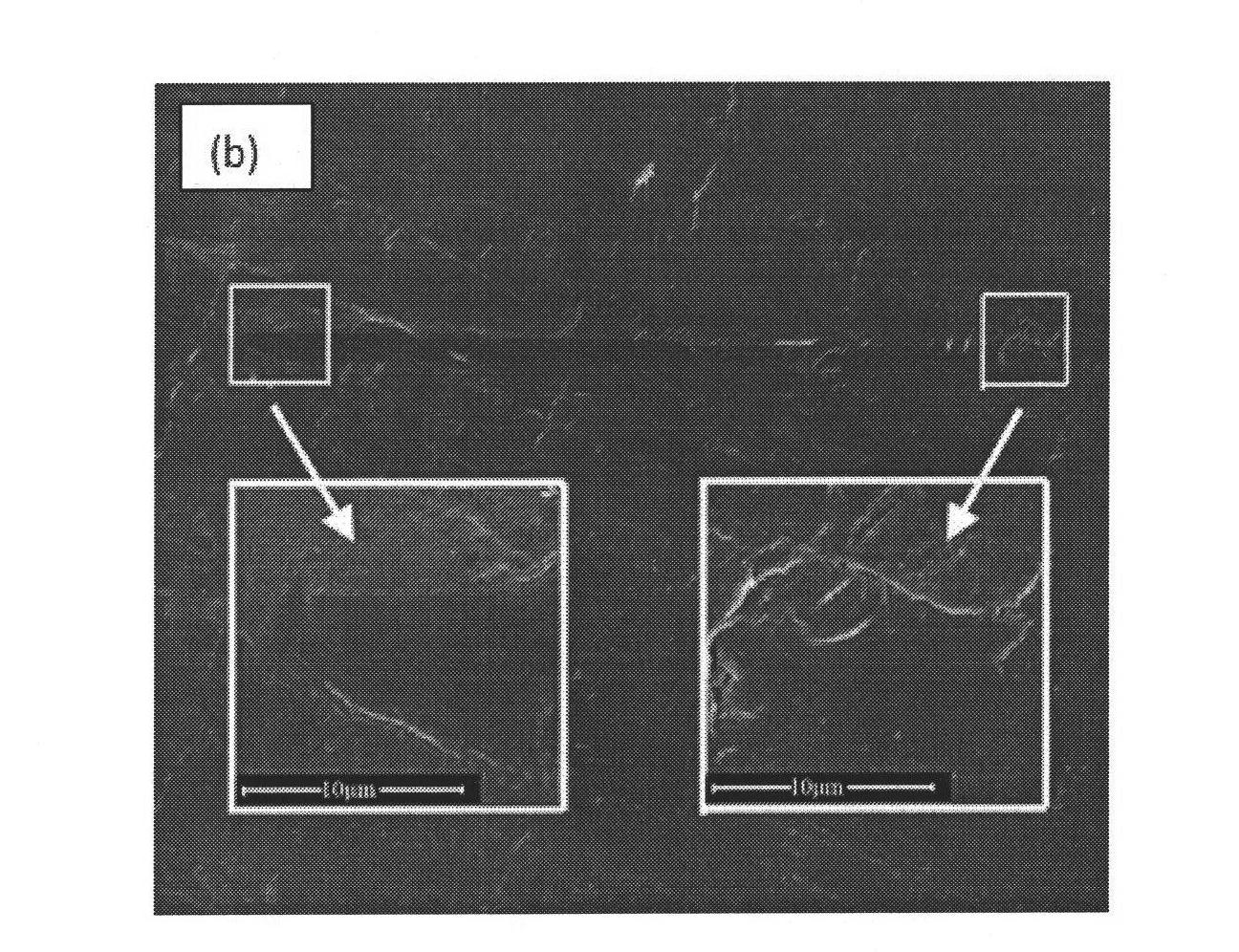

[0036] Figure 4 It is the wear morphology diagram after the friction and wear test of the UHMWPE artificial joint socket treated by the method of this example. The experimental conditions are the same as the friction experiment in Example 1. Depend on Figure 4 It can be seen that the artificial joint socket treated by the argon plasma method in this example has no cracking and peeling except for a small amount of plastic deformation and furrow, indicating that the wear resistance of the surface of the UHMWPE artificial joint socket has been improved. Embodiment 3-12

Embodiment 3~12

[0037] The operation of embodiment 3~12 is basically the same as embodiment 1, and the concrete parameter during just operation changes to some extent, and its concrete parameter is as follows: (for the convenience of comparison, the parameter of embodiment 1 and embodiment 2 is also listed in the table .)

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com