Stripping processing method of textile printing defective items

A technology for textile printing, dyeing, and processing methods, which is applied in the field of photocatalytic low-temperature peeling, can solve the problems of large chemical consumption, chemical environmental threats, low thermal initiation efficiency, etc., and achieves less pollutant residues and high initiation and catalytic efficiency. , the effect of simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

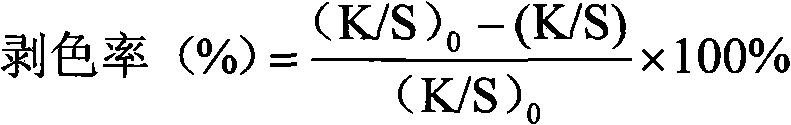

[0020] The present embodiment adopts hydrogen peroxide (H 2 o 2 ) the ultraviolet light low temperature triggers the impregnation catalytic stripping method to carry out the stripping process to the dyed defective products, and the stripping solution is composed of a concentration of 1.20g L -1 of hydrogen peroxide (H 2 o 2 ) aqueous solution, and adjust the pH of the solution to 4.0; then add it to the reaction device at a bath ratio of 1:50.

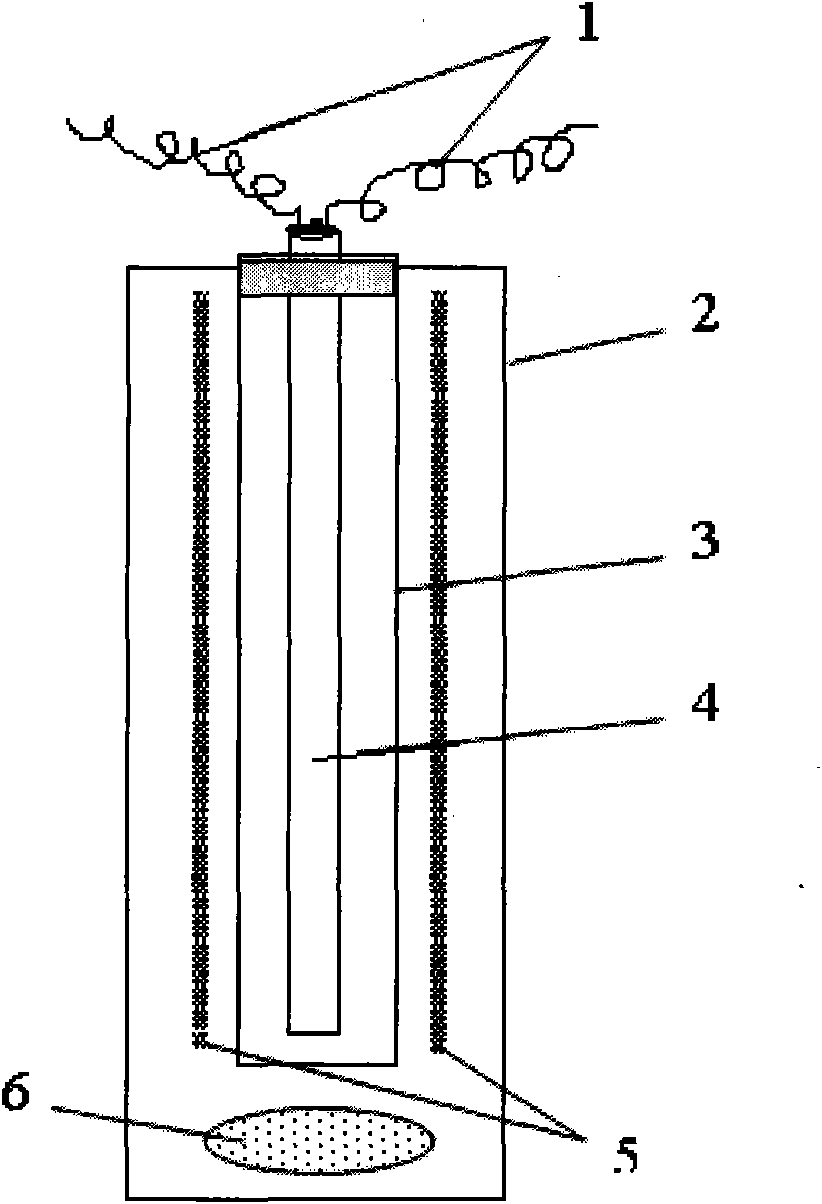

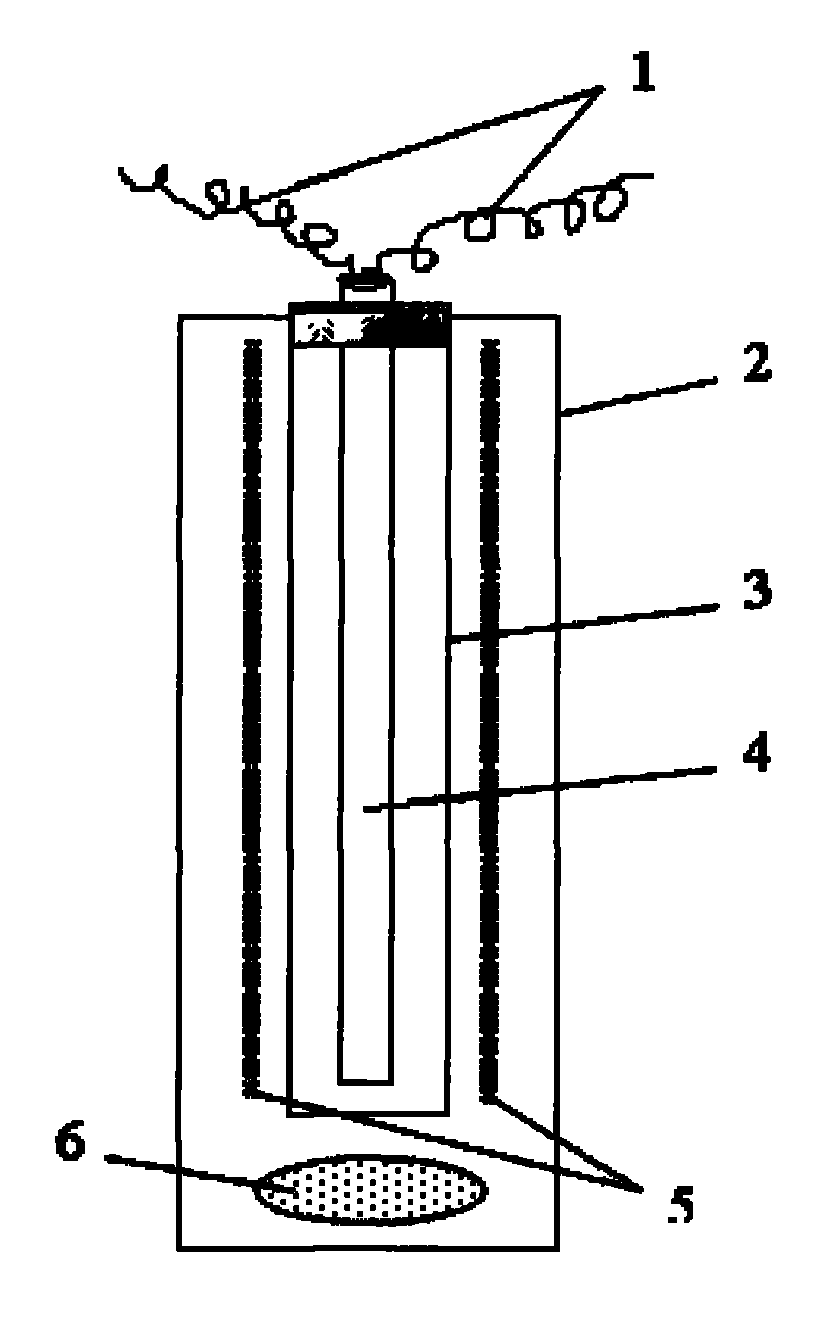

[0021] The reaction device used in this embodiment is a batch reaction device. See attached figure 1 , in the intermittent processing unit 2, install the oxygen increasing device 6, adopt the oxygen increasing pump to constantly pass into air in the stripping bath; Install the quartz glass tube 3 and the low-pressure mercury lamp 4, the present embodiment is with 1 8W low-pressure mercury lamp It is an ultraviolet light source, and the power connection 1 (power supply is not shown) is connected to a low-pressure mercury lamp. Afte...

Embodiment 2

[0036] The present embodiment adopts hydrogen peroxide (H 2 o 2 ) The ultraviolet light low temperature triggers the padding catalytic stripping method to carry out the stripping treatment on the dyed defective products. According to the bath ratio of 1:30, it contains 0.90g L -1 Hydrogen peroxide aqueous solution, adjust pH to 6.0, use this solution as padding liquid, with the dyed cotton fabric defective product in embodiment 1 two dipping two rollings (passing off rate is 100%), then fabric is placed in the attached figure 1 Middle quartz casing 3 periphery, according to the method for embodiment 1, carry out photocatalytic stripping place 20min and 40min respectively under room temperature condition (25 ℃) to the cotton fabric dyed with reactive red M-3BE 100% dyestuff, its specific steps And other conditions are as described in Example 1.

[0037] Table 2 is the result of the catalytic stripping test of reactive red M-3BE 100% dyed defective products using the method d...

Embodiment 3

[0042] The present embodiment adopts potassium persulfate (K 2 S 2 o 8 ) the ultraviolet light low temperature triggers the impregnation catalytic stripping method to carry out the stripping process to the dyed defective products, and the stripping solution is 0.60g L respectively -1 and 2.00g L -1 Potassium persulfate (K 2 S 2 o 8 ) aqueous solution, and adjust the pH of the solution to 2.0. Then join in the batch reaction device by the bath ratio of 1: 30, press the method for embodiment 1, carry out photocatalytic stripping 30min under room temperature condition (20 ℃) to the dyed defective product of cotton fabric in embodiment 1, its The steps and other conditions are as described in Example 1.

[0043] Table 3 is the result of the catalytic stripping test of reactive red M-3BE 100% dyed defective products using the method described in this example.

[0044] table 3

[0045]

[0046] As can be seen from the data shown in table 3, even at the lower concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com