Anti-solder-adhering flame-retardant ABS modified resin and preparation method thereof

A technology of ABS resin and modified resin, which is applied in the field of modified resin and its preparation, can solve problems such as increasing the contact area between parts and tin bath, low thermal decomposition temperature of flame retardants, and threats to life and property safety, so as to reduce viscosity. Risks of tin, reduction of usage, effects of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

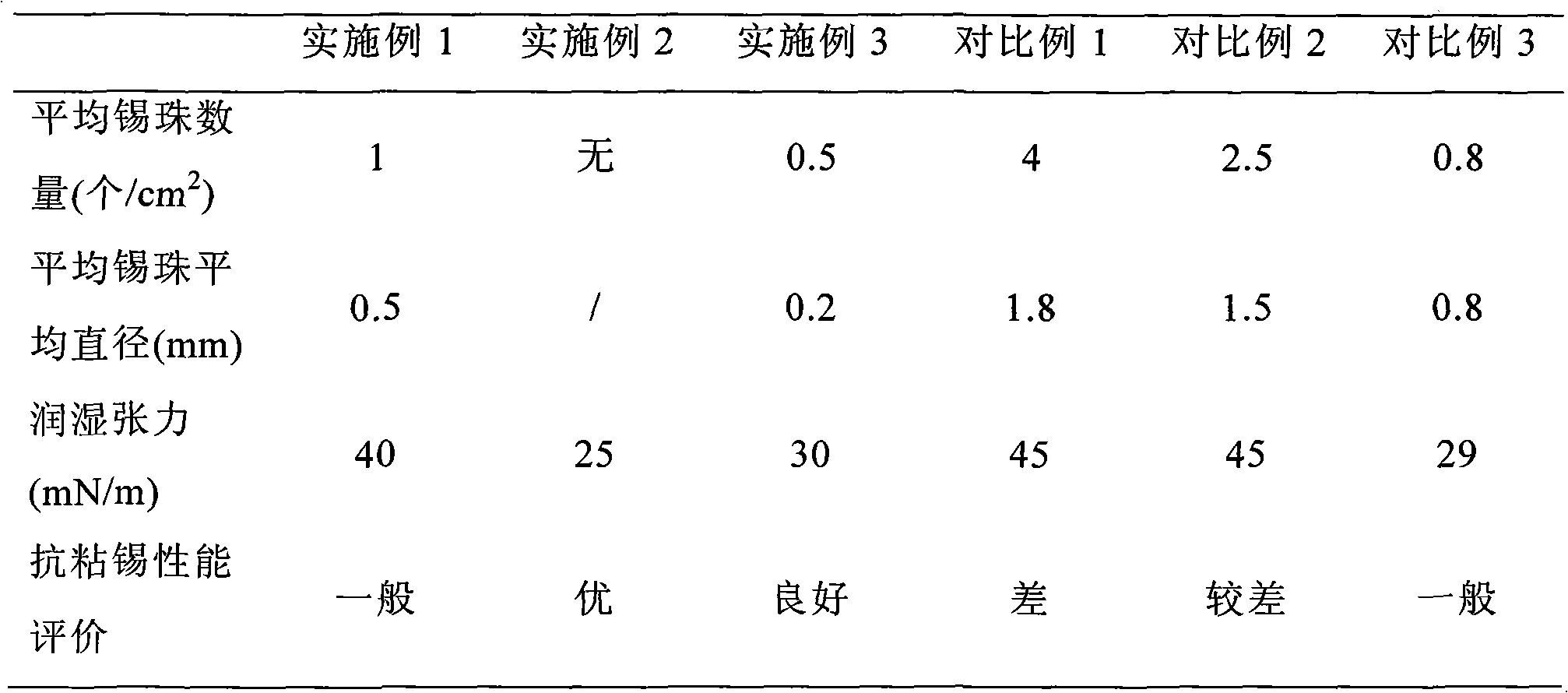

Embodiment 1

[0049] A preparation method of an anti-sticking tin-resistant flame-retardant ABS modified resin, the method comprising the following steps:

[0050] (1) Prepare materials according to the following components and contents: 100kg ABS resin, 20kg brominated flame retardant FR245, 6kg antimony-based flame retardant antimony pentoxide, 20kg heat-resistant masterbatch, 0.3kg anti-dripping agent polytetrafluoroethylene (PTFE), 0.5kg low surface energy active substance polyethylene wax, 0.3kg antioxidant, 0.5kg lubricant, wherein ABS resin is PA757, purchased from Taiwan CHIMEI company; FR245, bromine content is 67%, purchased from Israel Dead Sea Bromide Company; antimony pentoxide was purchased from Hunan Shanxing; heat-resistant masterbatch, which is homemade ABS resin loaded with heat-resistant agent styrene-N-phenylmaleimide-maleic anhydride terpolymer, Heat-resistant agent content is 20% (wt%); Antioxidant is Irganox 1076, purchased from Ciba; PTFE is purchased from Guangzhou ...

Embodiment 2

[0053] A preparation method of a tin-sticking-resistant flame-retardant ABS modified resin, the method comprising the following steps: 100kg ABS resin, 20kg brominated flame retardant FR245, 6kg antimony-based flame retardant antimony pentoxide, 20kg heat-resistant masterbatch , 0.3kg anti-dripping agent polytetrafluoroethylene (PTFE), 0.5kg low surface energy active material polyvinylidene fluoride, 0.3kg antioxidant, 0.5kg lubricant, wherein ABS resin is PA757, purchased from Taiwan CHIMEI company ; The bromine content of FR245 is 67%, which was purchased from Dead Sea Bromine Company of Israel; Antimony pentoxide was purchased from Hunan Shanxing; The ABS resin of toic anhydride terpolymer, heat resistant agent content is 70% (wt%); Antioxidant is Irganox 1076, purchased from Ciba company; PTFE is purchased from Guangzhou Entropy Energy Polymer Company; Polyvinylidene fluoride is purchased from 3M Company; the lubricant is commercially available EBS (ethylene bisstearamide)...

Embodiment 3

[0056] A preparation method of a tin-sticking-resistant flame-retardant ABS modified resin, the method comprising the following steps: 100kg ABS resin, 20kg brominated flame retardant FR245, 6kg antimony-based flame retardant antimony pentoxide, 20kg heat-resistant masterbatch , 0.3kgPTFE, 0.5kg low surface energy active material siloxane, 0.3kg antioxidant, 0.5kg lubricant, wherein the ABS resin is PA757, purchased from Taiwan CHIMEI company; the bromine content of FR245 is 67%, purchased from Israel Dead Sea Bromine Company; antimony pentoxide was purchased from Hunan Shanxing; the heat-resistant masterbatch was homemade ABS resin loaded with polyurethane, and the heat-resistant agent content was 50% (wt%); the antioxidant was Irganox 1076, purchased from Ciba company PTFE was purchased from Guangzhou Entropy Energy Polymer Co., Ltd.; siloxane was purchased from Dow Corning Corporation of the United States; the lubricant was commercially available EBS (ethylene bis stearic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com