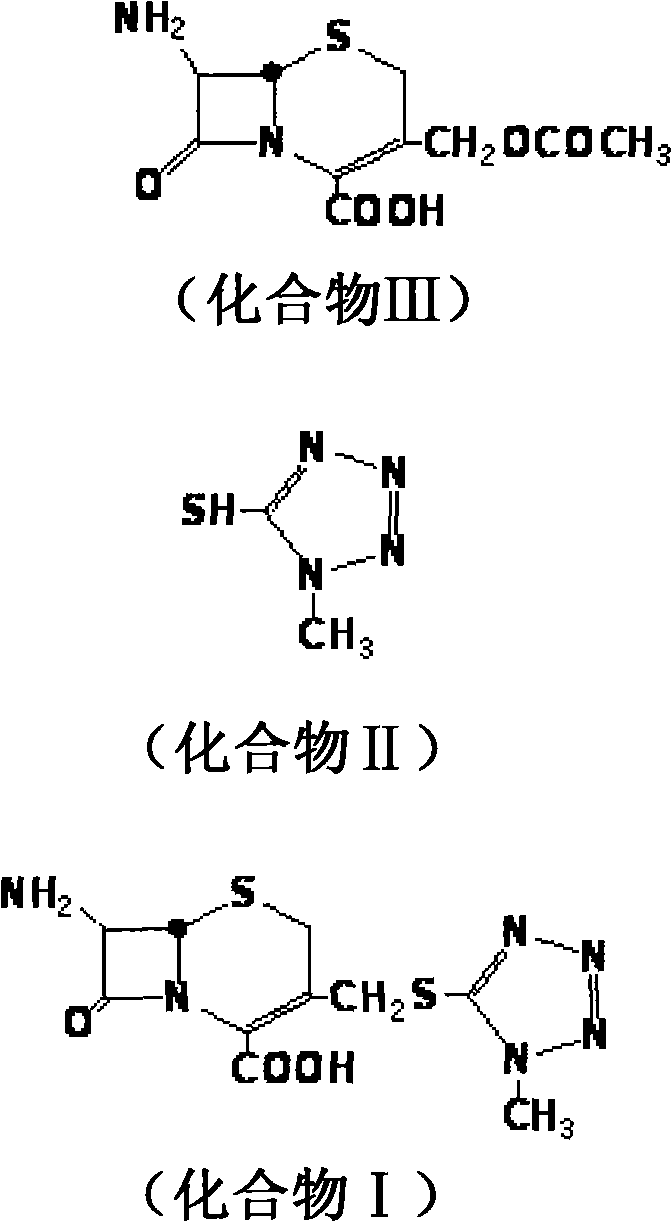

Preparation method of 7-aminocephalo-5-mercapto-1-methyltetrazole

A technology for tetrazolium and amino cephalosporins is applied in the field of preparation of cephalosporin intermediates 7-aminocephedrine tetrazolium, and can solve the problems of low content, poor quality, poor stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In a dry reaction flask, add 272g (1.0mol) of 7-ACA, 140g (1.2mol) of 5-mercapto-1-methyltetrazole and 1500ml of acetonitrile, cool to 0°C, add 1200ml of boron trifluoride-acetonitrile solution, Raise the temperature to 25°C, stir for 3 hours, and cool to 0°C in an ice bath. Under stirring, pour the reaction solution into 2000ml of 0.25% sodium bisulfite solution containing 0.5g EDTA pre-cooled to 0°C, adjust the pH of the solution to 2.5 with ammonia water at 0-2°C, continue stirring for 1h, filter, and filter cake Wash with acetonitrile, 30ml of water and acetone, and dry under vacuum below 40°C to obtain 298g of white powder with a weight yield of 110% and a melting point of 263-265°C.

Embodiment 2

[0016] In a dry reaction bottle, add 7-ACA 272g (1.0mol), 5-mercapto-1-methyltetrazole 140g (1.2mol) and acetonitrile 1500ml, cool to 5°C, add boron trifluoride-acetonitrile solution 1200ml, Raise the temperature to 25°C, stir for 3 hours, and cool to 5°C in an ice bath. Under stirring, pour the reaction solution into 2000ml of 0.25% sodium bisulfite solution containing 0.5g EDTA pre-cooled to 5°C, adjust the pH of the solution to 2.5 with ammonia water at 0-2°C, continue stirring for 1h, filter, and filter cake Wash with acetonitrile, 30ml of water and acetone, and dry under vacuum at below 40°C to obtain 305g of white powder with a weight yield of 112% and a melting point of 263-265°C.

Embodiment 3

[0018] In a dry reaction bottle, add 7-ACA 272g (1.0mol), 5-mercapto-1-methyltetrazole 140g (1.2mol) and acetonitrile 1500ml, cool to 5°C, add boron trifluoride-acetonitrile solution 1200ml, Raise the temperature to 30°C, stir for 3 hours, and cool to 0°C in an ice bath. Under stirring, pour the reaction solution into 2000ml of 0.25% sodium bisulfite solution containing 0.5g EDTA pre-cooled to 0°C, adjust the pH of the solution to 2.5 with ammonia water at 0-2°C, continue stirring for 1h, filter, and filter cake Wash with acetonitrile, 30ml of water and acetone, and dry under vacuum at below 40°C to obtain 302g of white powder with a weight yield of 111% and a melting point of 263-265°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com