Preparation method of bismuth telluride based bulk nano crystalline thermoelectric material

A thermoelectric material, bismuth telluride technology, which is applied in the manufacture/processing of thermoelectric devices, etc., can solve the problems of inability to effectively reduce the sintering temperature, difficult to meet the development of industrialization, and uneven performance of the sintered body, so as to reduce the thermal conductivity of the lattice. , The effect of short sintering time and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a bismuth telluride-based bulk nanocrystalline thermoelectric material, the preparation method is as follows:

[0030] Preparation of Bismuth Telluride-Based Alloy Nanopowders by Mechanical Alloying in the First Step

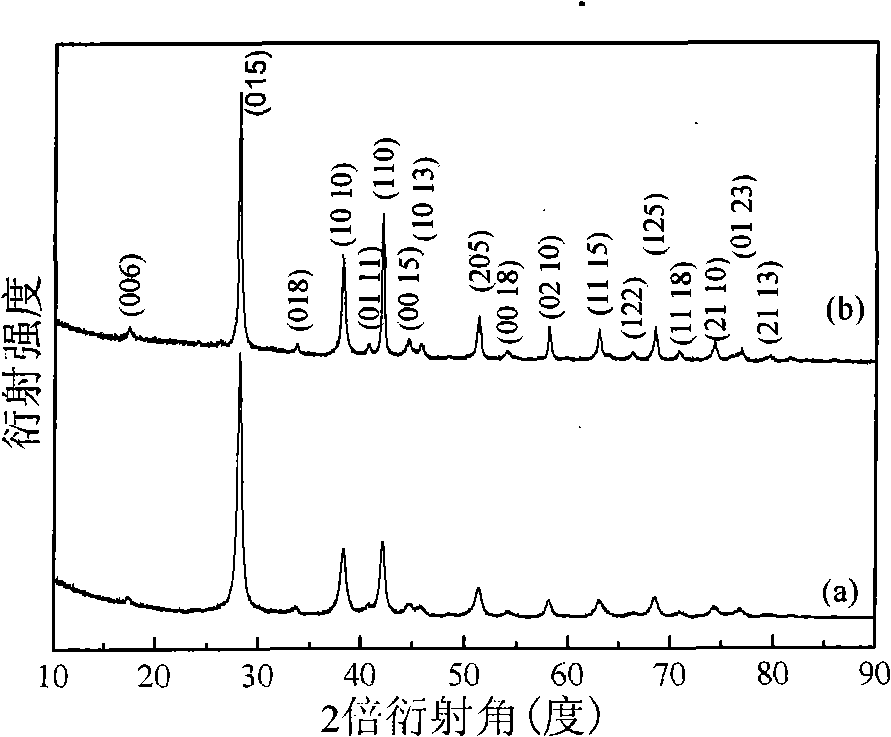

[0031] Using Bi, Sb and Te elemental powders with a mass percentage greater than 99.99% as raw materials, according to (Sb x Bi 1-x ) 2 Te 3 The ingredients of the chemical formula, 0.75≤x≤0.78, are uniformly mixed, and then ball milled with a ball mill to prepare bismuth telluride-based alloy nano powder.

[0032] The technical parameters of the ball milling treatment described in this embodiment are: the mass ratio of balls to materials is 20:1-25:1, the rotational speed of the ball mill is 300-350 r / min, the ball milling time is 30-42 hours, and an inert gas protection is used during ball milling.

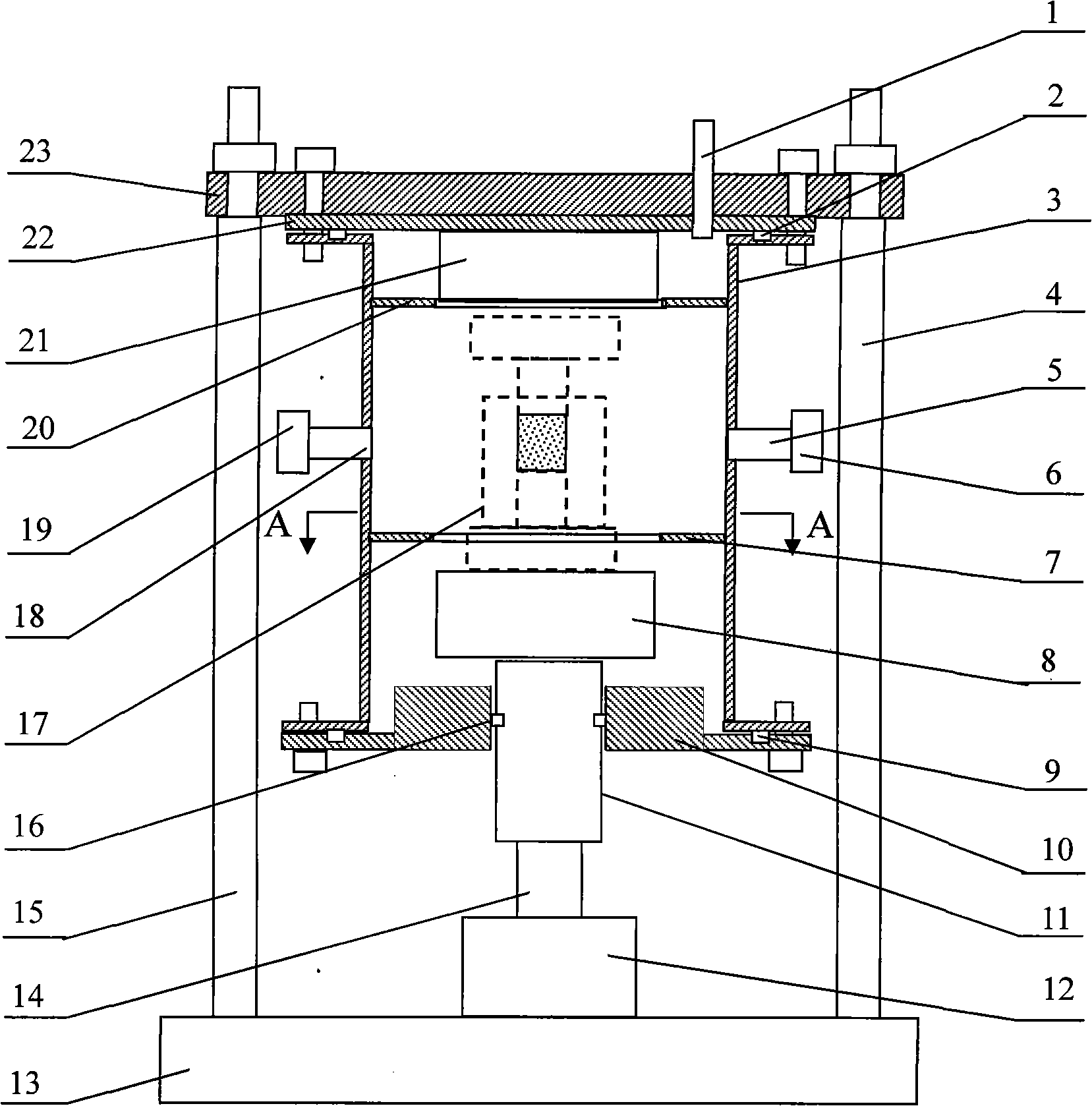

[0033] Preparation of Bismuth Telluride-Based Bulk Nanocrystalline Thermoelectric Materials by Microwave Irradiation and Pressur...

Embodiment 2

[0037] A method for preparing a bismuth telluride-based bulk nanocrystalline thermoelectric material. Except following technical parameter, all the other are with embodiment 1:

[0038] Preparation of Bismuth Telluride-Based Alloy Nanopowders by Mechanical Alloying in the First Step

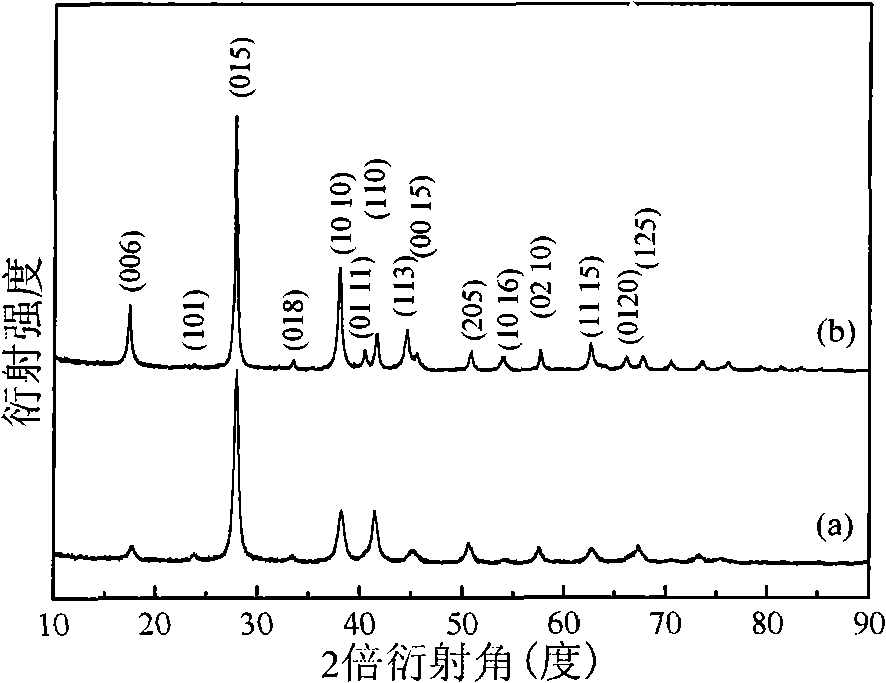

[0039] Press (Sb x Bi 1-x ) 2 Te 3 Chemical formula ingredients, 0.78≤x≤0.80;

[0040] The technological parameters of the ball milling treatment are: the mass ratio of balls to materials is 15:1-20:1, the rotational speed of the ball mill is 350-400r / min, and the ball milling time is 20-30h.

[0041] Preparation of Bismuth Telluride-Based Bulk Nanocrystalline Thermoelectric Materials by Microwave Irradiation and Pressure Sintering in the Second Step

[0042] The temperature is raised to 420-450° C. under the condition that the pressure applied to the powder is 20-25 MPa, and then the temperature is kept for 20-30 minutes under the condition that the pressure applied to the powder is 55-60 ...

Embodiment 3

[0045] A method for preparing a bismuth telluride-based bulk nanocrystalline thermoelectric material. Except following technical parameter, all the other are with embodiment 1:

[0046] Preparation of Bismuth Telluride-Based Alloy Nanopowders by Mechanical Alloying in the First Step

[0047] Press (Sb x Bi 1-x ) 2 Te 3 Chemical formula ingredients, 0.80≤x≤0.82;

[0048] The technological parameters of the ball milling treatment are: the mass ratio of balls to materials is 20:1-25:1, the rotational speed of the ball mill is 450-500r / min, and the ball-milling time is 60-72h.

[0049] Preparation of Bismuth Telluride-Based Bulk Nanocrystalline Thermoelectric Materials by Microwave Irradiation and Pressure Sintering in the Second Step

[0050] The temperature is raised to 350-420° C. under the condition that the pressure applied to the powder is 25-35 MPa, and then the temperature is kept for 45-60 minutes under the condition that the pressure applied to the powder is 38-48 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com