Lamella heat exchanger and manufacturing method thereof and lamella evaporative condensing equipment

A technology of condensing equipment and heat exchangers, which is applied in the field of plate and shell evaporative steam condensing equipment, plate and shell heat exchangers and their manufacturing, and can solve the problems of lower heat exchange efficiency, poor heat exchange and cooling effect, and poor heat exchange effect and other problems, to achieve the effect of good heat transfer effect, high heat transfer efficiency and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

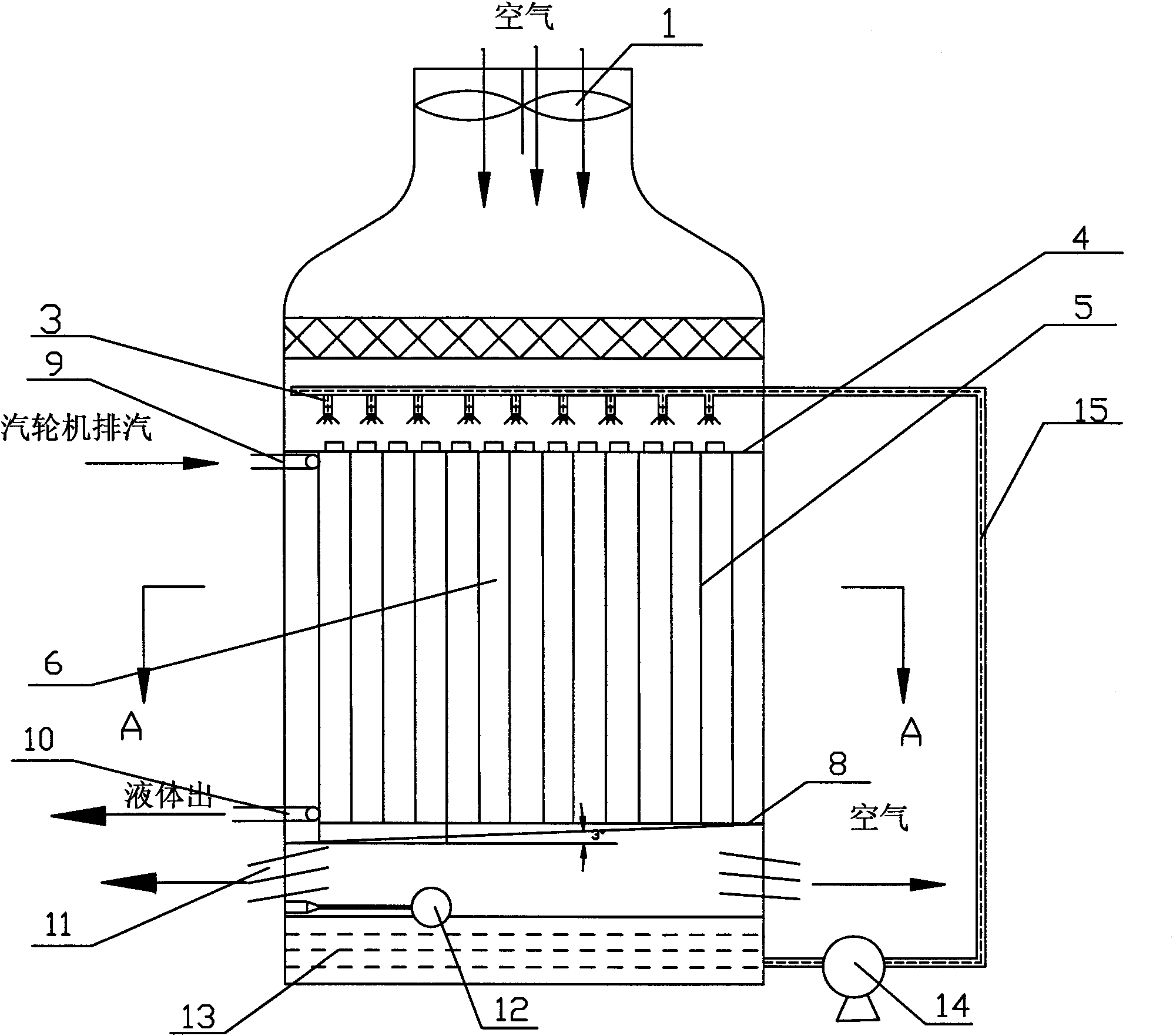

[0031] Attached below figure 1 The parallel-flow plate-shell evaporative and condensing equipment in the present invention is described.

[0032] Such as figure 1 As shown, the plate-shell evaporative steam-condensing equipment of the present invention includes a rectangular parallelepiped upper box, a lower box and a plate-shell heat exchanger 6 . There is an air inlet on the top of the upper box, and a fan 1 and a spray device 3 are arranged in sequence below the air inlet to realize the air circulation and water distribution of the condensing equipment; the plate-shell heat exchanger 6 is located in the spray device 3 The lower part is connected to the upper box by bolts or welding; the lower part of the lower box is lower than the plate and shell heat exchanger 6. There is an air outlet grid 11, which can make the humid air move out of the lower box in time, and at the same time, the lower box The bottom is also provided with a water collection tank 13 and a float valve ...

Embodiment 2

[0036] Such as figure 2 As shown, it is a cross-flow plate-shell evaporative steam condensing device. This embodiment is similar to Embodiment 1, the difference is that the position of the air outlet and the fan 1 are set at the top of the upper box, next to the air inlet, and at the same time There is also a section of PVC packing layer 7 under the plate and shell heat exchanger 6. When the hot and humid circulating water passes through the packing layer, the contact time between it and the packing layer 7 is prolonged, thereby better reducing the circulating water temperature. The filler layer 7 and the side of the plate-shell heat exchanger 6 close to the air outlet are also provided with a water baffle 2 for guiding the spray water flowing out of the plate-shell heat exchanger 6 to the PVC filler.

Embodiment 3

[0038] The manufacturing process of the combined plate and shell evaporative steam condensing equipment with the plate and shell heat exchanger of the present invention comprises the following steps:

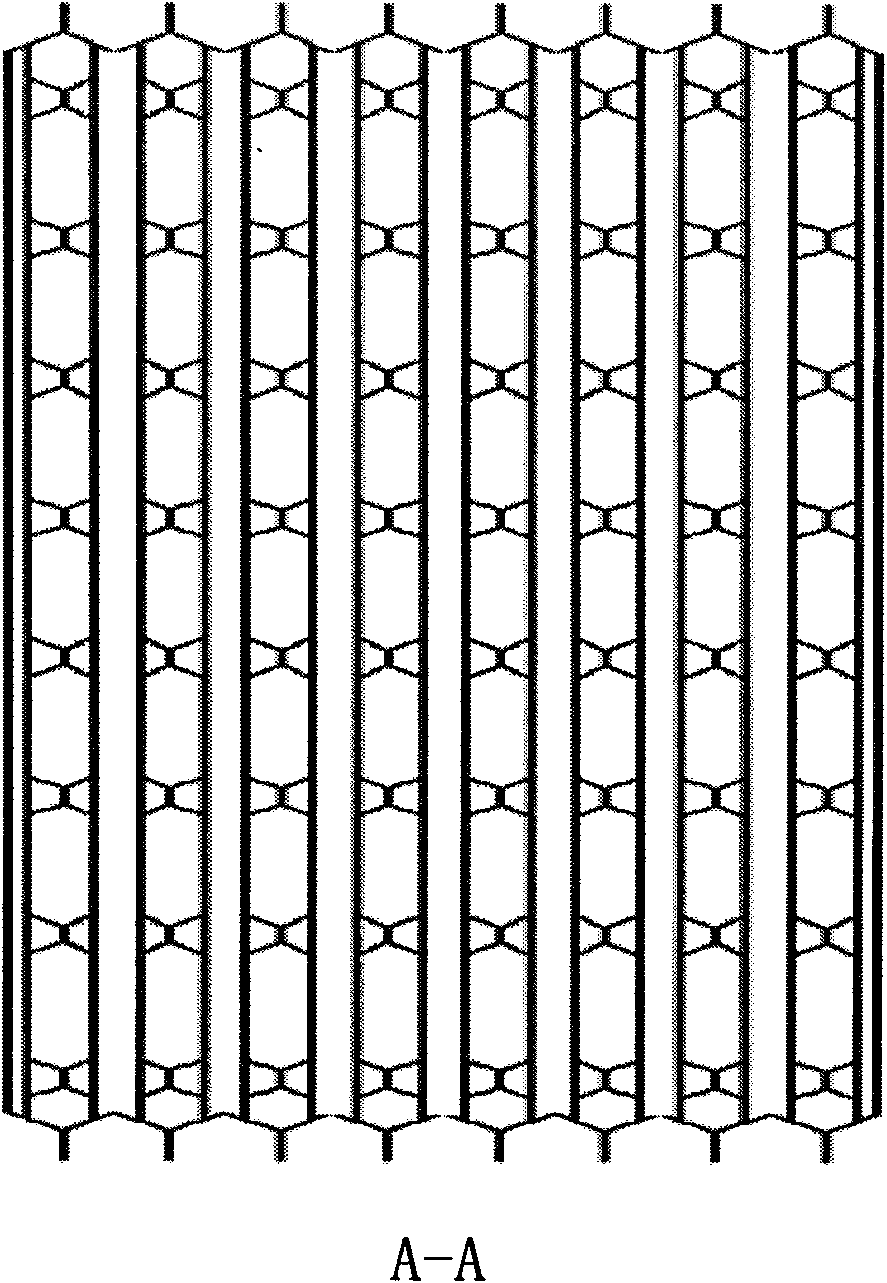

[0039] A. First stamp the stainless steel plate to form transverse and longitudinal grooves and / or flanges, and process one end of it into a sawtooth structure to obtain a heat exchange plate unit;

[0040] B. Then take two heat exchange plate units, fold the heat exchange plate flange to flange, and groove to groove symmetrically, and weld the adjacent longitudinal edges and transverse edges of the heat exchange plate to form a Integral, forming a single heat exchange plate bundle, such as Figure 4 , 5 shown;

[0041] C. Take a plurality of plate-shell heat exchange plate bundles 5, symmetrically overlap the flanges of the heat exchange plate bundles with the flanges, and the grooves with the grooves. The edges are correspondingly welded into one;

[0042] D. Weld the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com