Microchannel heat exchange-based waste-heat direct power generation device

A technology of micro-channel heat exchanger and power generation device, which is applied in the direction of generators/motors, electrical components, etc., can solve problems such as changes, achieve strong heat exchange capacity, good heat exchange effect, and ensure temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

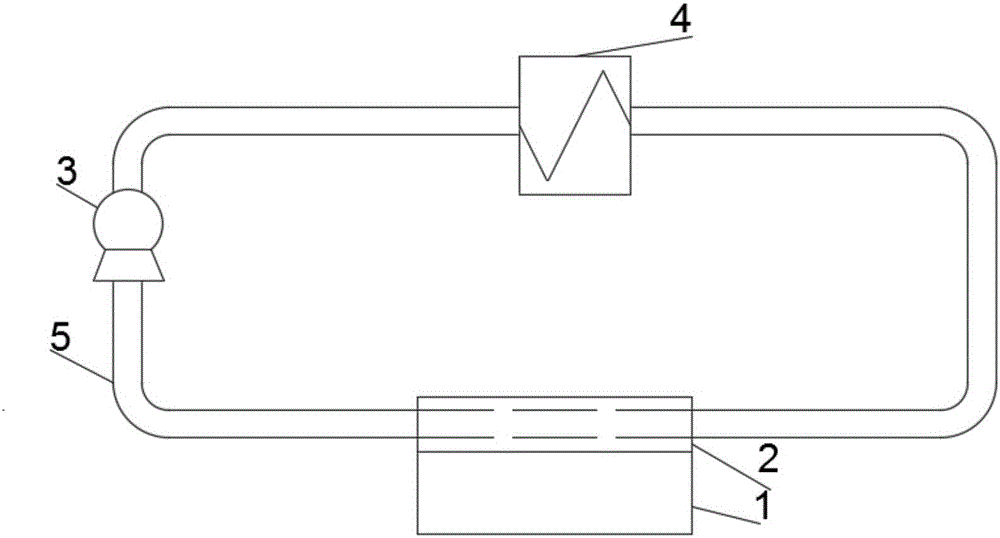

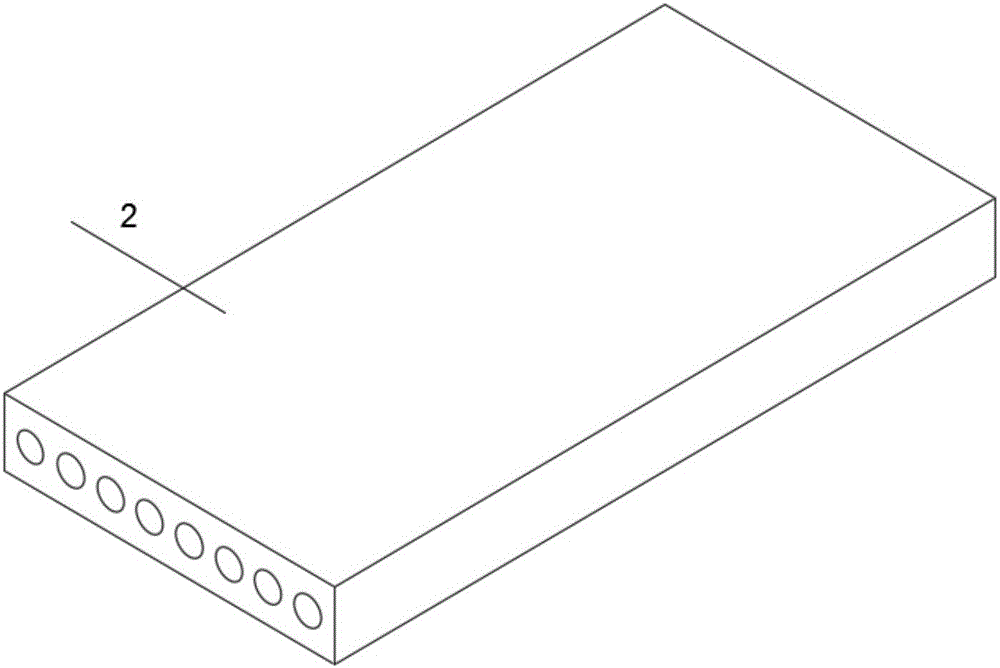

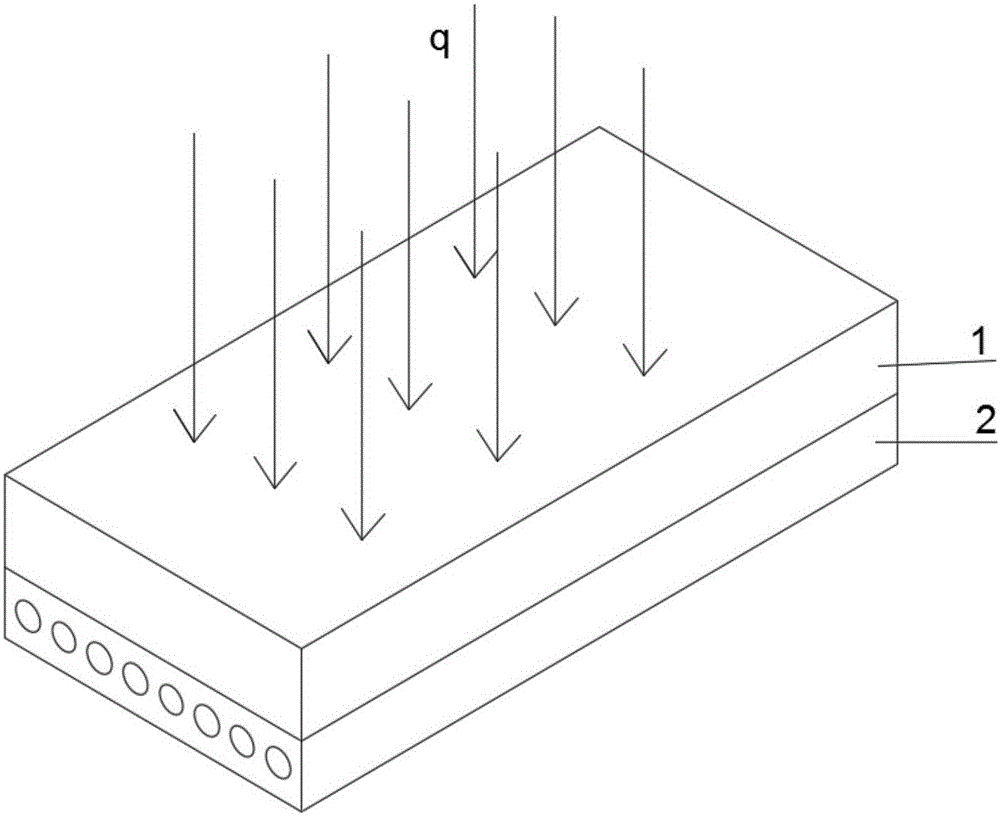

[0018] Embodiment 1: The power generation device includes thermoelectric material 1, microchannel heat exchanger 2, working medium pump 3, common heat exchanger 4 and pipeline 5; microchannel heat exchanger 2, working medium pump 3 and common heat exchanger 4 are connected in series through the pipeline 5 to form a closed-loop channel. The working medium flows through the circulation of boiling and liquefaction in the closed channel, and the cold end surface of the thermoelectric material 1 is in close contact with the end surface of the microchannel heat exchanger 2 .

[0019] The working medium is R30 or R21, and the working medium in the microchannel of the microchannel heat exchanger 2 and the cold end of the thermoelectric material 1 perform high-efficiency boiling heat exchange, so that the cold end of the thermoelectric material 1 maintains a stable low temperature condition, ensuring that the thermoelectric Conversion efficiency: The boiling working fluid transfers heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com