Heat dissipating working medium of heat radiator and preparation method thereof

A heat dissipation working fluid and heat sink technology, which is applied in the field of heat dissipation, can solve the problems of base fluid thermal conductivity decline, reduced heat transfer effect, high fluid viscosity, etc., and achieve stable working conditions, good heat transfer effect, and high specific heat capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

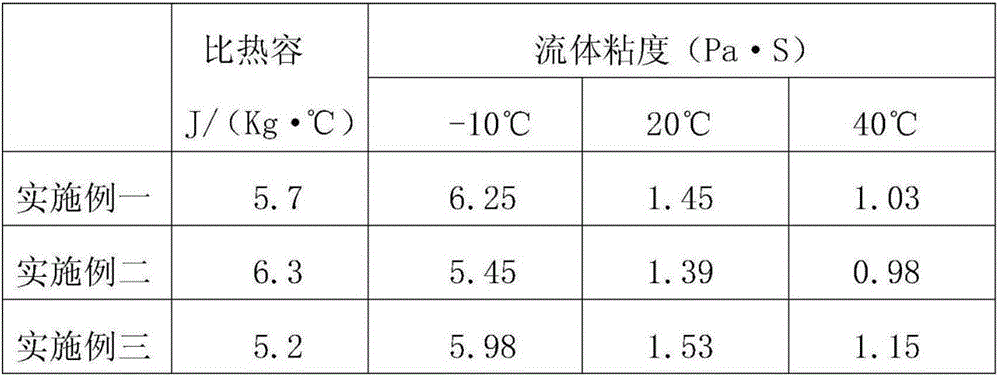

Examples

Example Embodiment

[0014] Example 1

[0015] A kind of preparation method of the radiating working medium of radiator, is made by following steps:

[0016] (1) Weigh the following raw materials in parts by weight: 5 parts of n-octadecane, 3 parts of glycerol, 6 parts of triazole toluene, 1 part of ethyl acetate, 5 parts of phenoxyethanol, 2 parts of diethanolamine, acetone 3 parts, 1 part of methanol, 3 parts of isopropanol and 20 parts of distilled water;

[0017] (2) The distilled water, n-octadecane, glycerol, triazole toluene, ethyl acetate and phenoxyethanol weighed in step (1) were added to the mixing tank in turn for stirring and mixing, and heated to 50°C, and kept the temperature 5min;

[0018] (3) Add the diethanolamine, acetone, methanol and isopropanol weighed in step (1) into the mixing tank in sequence for stirring and mixing, and heat to 30° C., and maintain the temperature for 10 min;

[0019] (4) After cooling, use a filter to perform secondary filtration to remove impurities...

Example Embodiment

[0020] Example 2

[0021] A kind of preparation method of the radiating working medium of radiator, is made by following steps:

[0022] (1) Weigh the following raw materials in parts by weight: 7 parts of n-octadecane, 4 parts of glycerol, 7 parts of triazole toluene, 2 parts of ethyl acetate, 7 parts of phenoxyethanol, 4 parts of diethanolamine, acetone 4 parts, methanol 2 parts, isopropanol 4 parts and distilled water 25 parts;

[0023] (2) The distilled water, n-octadecane, glycerol, triazole toluene, ethyl acetate and phenoxyethanol weighed in step (1) were added to the mixing tank in turn for stirring and mixing, and heated to 50°C, and kept the temperature 5min;

[0024] (3) Add the diethanolamine, acetone, methanol and isopropanol weighed in step (1) into the mixing tank in sequence for stirring and mixing, and heat to 30° C., and maintain the temperature for 10 min;

[0025] (4) After cooling, use a filter to perform secondary filtration to remove impurities.

Example Embodiment

[0026] Example 3

[0027] A kind of preparation method of the radiating working medium of radiator, is made by following steps:

[0028] (1) Weigh the following raw materials in parts by weight: 9 parts of n-octadecane, 5 parts of glycerol, 8 parts of triazole toluene, 3 parts of ethyl acetate, 9 parts of phenoxyethanol, 5 parts of diethanolamine, acetone 5 parts, methanol 3 parts, isopropanol 5 parts and distilled water 30 parts;

[0029] (2) The distilled water, n-octadecane, glycerol, triazole toluene, ethyl acetate and phenoxyethanol weighed in step (1) were added to the mixing tank in turn for stirring and mixing, and heated to 50°C, and kept the Temperature 5min;

[0030] (3) Then add the diethanolamine, acetone, methanol and isopropanol weighed in step (1) into the mixing tank in sequence for stirring and mixing, and heat to 30° C., and maintain the temperature for 10 minutes;

[0031] (4) After cooling, use a filter to perform secondary filtration to remove impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com