Anti-erosion agent for concrete, preparation method and application thereof

An anti-corrosion agent and concrete technology, applied in the field of building materials, can solve problems affecting the safety of concrete structures, structural failure, low early strength, etc., achieve good freeze-thaw cycle resistance, maintain fluidity loss, reduce large The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of concrete anti-corrosion agent (this concrete anti-corrosion agent is the concrete anti-corrosion agent based on undisturbed ultrafine fly ash microbead), the method comprises the following steps:

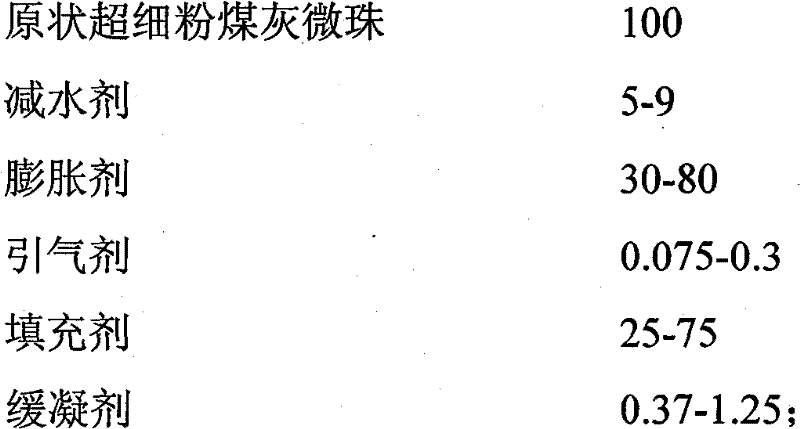

[0045] (1) Prepare materials according to the following components and content (Kg):

[0046]Undisturbed ultrafine fly ash microbeads 100

[0047] Lignosulfonate superplasticizer 6

[0048] Sulfoaluminate expansion agent 45

[0049] Sodium lauryl sulfate 0.03

[0050] Sodium dodecylbenzenesulfonate 0.08

[0051] Agglomerated silica fume 25

[0052] Trisodium citrate 0.3

[0053] Sodium gluconate 0.2

[0054] (2) Put the original ultrafine fly ash microbeads and water reducing agent into the dry powder mixer for mechanical mixing for 2-5 minutes;

[0055] (3) Put in expansion agent, air-entraining agent, filler, and setting retarder in sequence, and mix evenly. The total mechanical mixing time is 5-7 minutes to obtain the concrete anti-co...

Embodiment 2

[0058] A kind of preparation method of concrete anti-corrosion agent (this concrete anti-corrosion agent is the concrete anti-corrosion agent based on undisturbed ultrafine fly ash microbead), the method comprises the following steps:

[0059] (1) Prepare materials according to the following components and content (Kg):

[0060] Undisturbed ultrafine fly ash microbeads 100

[0061] Lignosulfonate superplasticizer 8

[0062] Sulfoaluminate expansion agent 70

[0063] Sodium lauryl sulfate 0.04

[0064] Sodium dodecylbenzenesulfonate 0.08

[0065] Agglomerated silica fume 50

[0066] Trisodium citrate 0.6

[0067] Sodium gluconate 0.4

[0068] (2) Put the original ultrafine fly ash microbeads and water reducing agent into the dry powder mixer for mechanical mixing for 2-5 minutes;

[0069] (3) Put in expansion agent, air-entraining agent, filler, and setting retarder in sequence, and mix evenly. The total mechanical mixing time is 5-7 minutes to obtain the concrete anti-c...

Embodiment 3

[0072] A kind of preparation method of concrete anti-corrosion agent (this concrete anti-corrosion agent is the concrete anti-corrosion agent based on undisturbed ultrafine fly ash microbead), the method comprises the following steps:

[0073] (1) Prepare materials according to the following components and content (Kg):

[0074] Undisturbed ultrafine fly ash microbeads 100

[0075] Lignosulfonate superplasticizer 7

[0076] Sulfoaluminate expansion agent 60

[0077] Sodium lauryl sulfate 0.04

[0078] Sodium dodecylbenzenesulfonate 0.09

[0079] Agglomerated silica fume 40

[0080] Trisodium citrate 0.4

[0081] Sodium gluconate 0.2

[0082] (2) Put the original ultrafine fly ash microbeads and water reducing agent into the dry powder mixer for mechanical mixing for 2-5 minutes;

[0083] (3) Put in expansion agent, air-entraining agent, filler, and setting retarder in sequence, and mix evenly. The total mechanical mixing time is 5-7 minutes to obtain the concrete anti-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com