A kind of modified limestone powder and its preparation method and concrete

A limestone powder and concrete technology, applied in the field of building materials, can solve problems such as sulfate corrosion of concrete, and achieve the effects of reducing porosity, green environmental protection cost, and improving sulfate corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

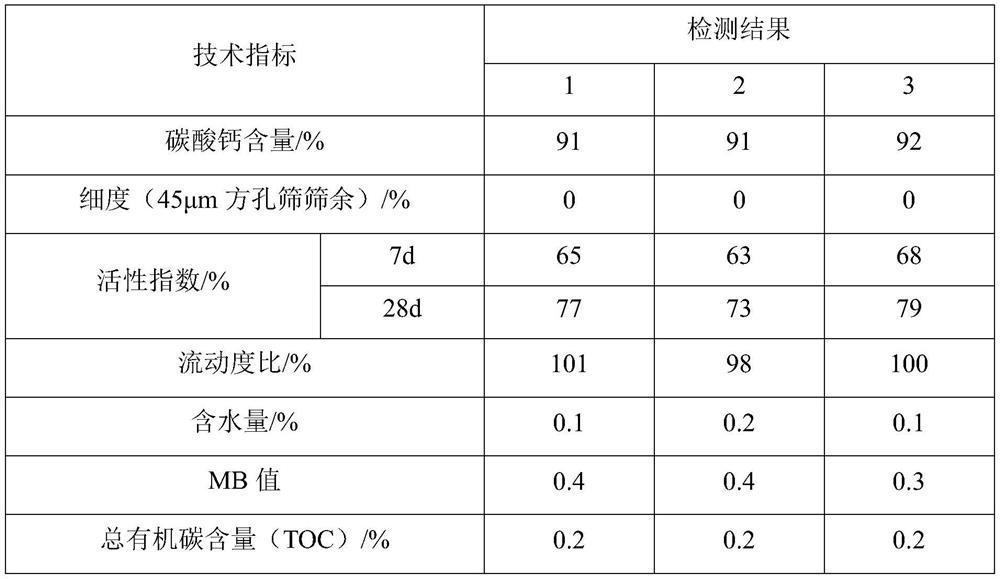

Examples

Embodiment Construction

[0024] In order to facilitate understanding, the present invention will be described more fully in conjunction with specific embodiments. However, the present invention can be implemented in many different forms, is not limited to the embodiments described herein. Conversely, the purpose of providing these embodiments is to make a more thorough understanding of the disclosure of the present invention.

[0025] All techniques and scientific terms used herein are identical to those skilled in the art, unless otherwise defined. The terminology used in the specification of the present invention is merely intended to describe the embodiments of the specific embodiments, and is not intended to limit the invention.

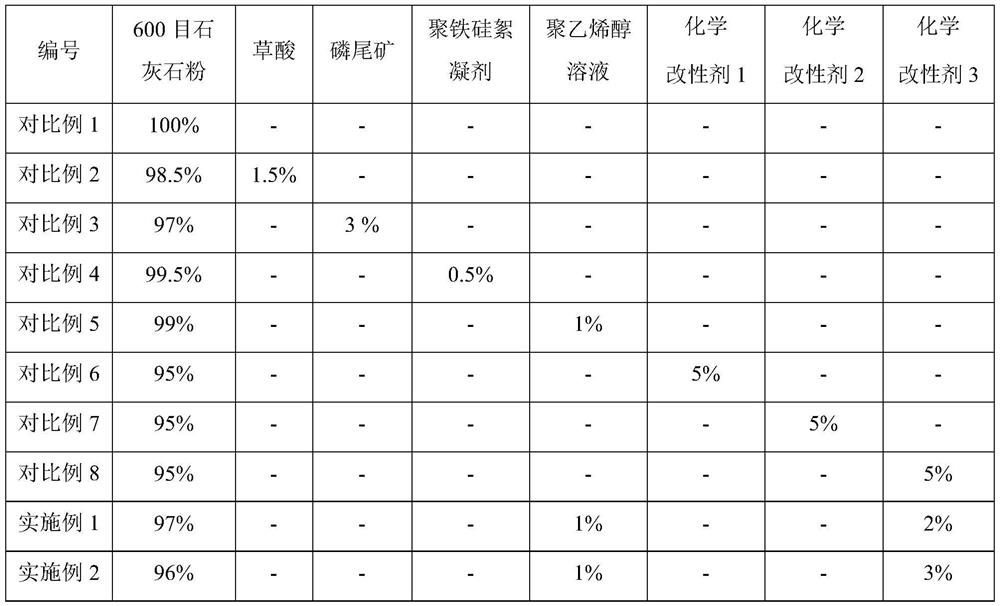

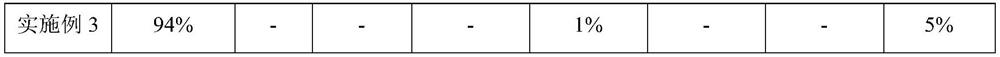

[0026] The preparation method of modified limestone powder in the following examples and comparative examples is: refer to the mass powder, physical modifier, and chemical modifier according to the mass percentage of the mass; then the limestone powder and the physics change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com