Sulfate-corrosion-resistance concrete additive and preparation method thereof

A concrete admixture and sulfate-resistant technology, which is applied in the field of building materials, can solve problems such as failure to achieve good results, and achieve the effects of improving the ability of sulfate corrosion resistance, wide application range, high social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

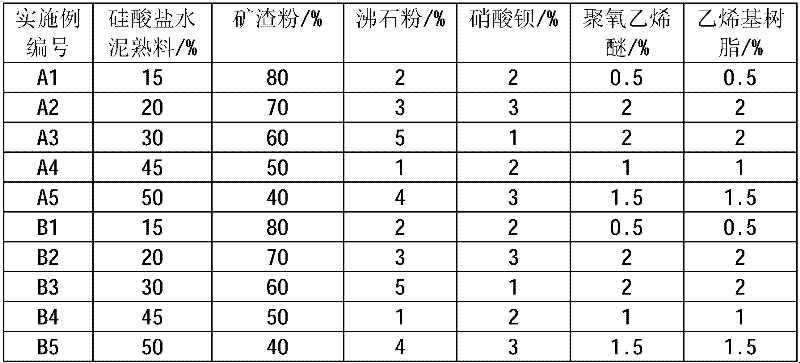

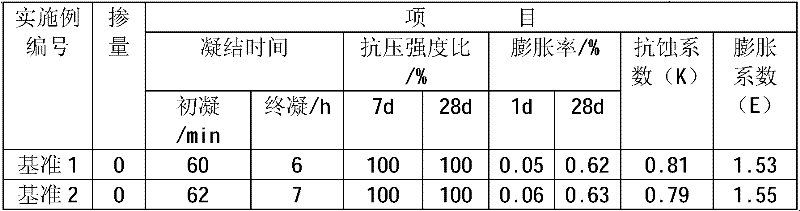

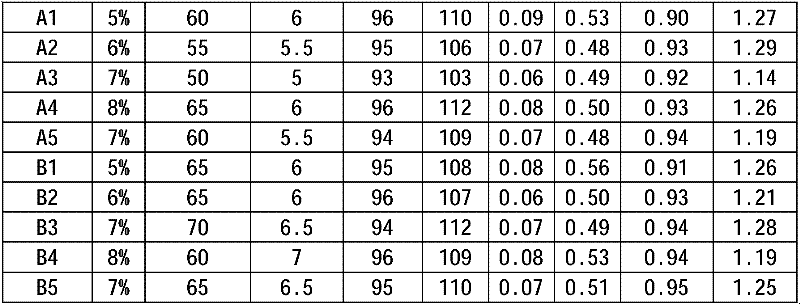

[0015] The present invention will be specifically described below in conjunction with the examples, but the present invention is not limited to the following examples. Two groups of benchmark mortars that meet the standard of "Concrete Anti-Sulphate Corrosion Anticorrosion Agent" are used as a comparison, and the numbers are benchmark 1 and benchmark 2.

[0016] 1. Admixture production

[0017] Group A cement clinker adopts the fineness of 350m produced by Jidong Cement Co., Ltd. 2 / kg, corresponding to cement clinker with a compressive strength of 45MPa at 28 days. Group B cement clinker adopts the fineness of 450m produced by Jidong Cement Co., Ltd. 2 / kg, corresponding to cement clinker with a compressive strength of 55MPa at 28 days. The other component materials are the same, the slag powder is S95 grade slag powder produced by Beijing Shougang Building Material Chemical Factory, and the technical indicators meet the domestic GB / T18046-2000 standard; the zeolite powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com