Novel ballast water treatment method and device

A treatment device and treatment method technology, applied in the direction of water/sewage multi-stage treatment, electrochemical water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of environmental secondary pollution, carcinogen chloroform, etc., and achieve The equipment is simple, easy to sterilize, and has a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Implementation example one is the method of the present invention; implementation example two is the device of the present invention.

[0053] Implementation example one

[0054] A new type of ballast water treatment method is characterized in that: no chemical substances are added during the treatment process, and it is realized only through a combination of mechanical, physical and electrochemical methods; it includes the following steps:

[0055] A. Mechanical treatment: remove organisms larger than 50 μm in ballast water by filtration;

[0056] B. Combined physical and electrochemical treatment: ultrasonically crushing and removing organisms and controlling the amount of hydroxyl free radicals produced to remove residual organisms in the ship's ballast water treated in step A;

[0057] C. Discharging the ship's ballast water that has been processed in step B.

Embodiment 2

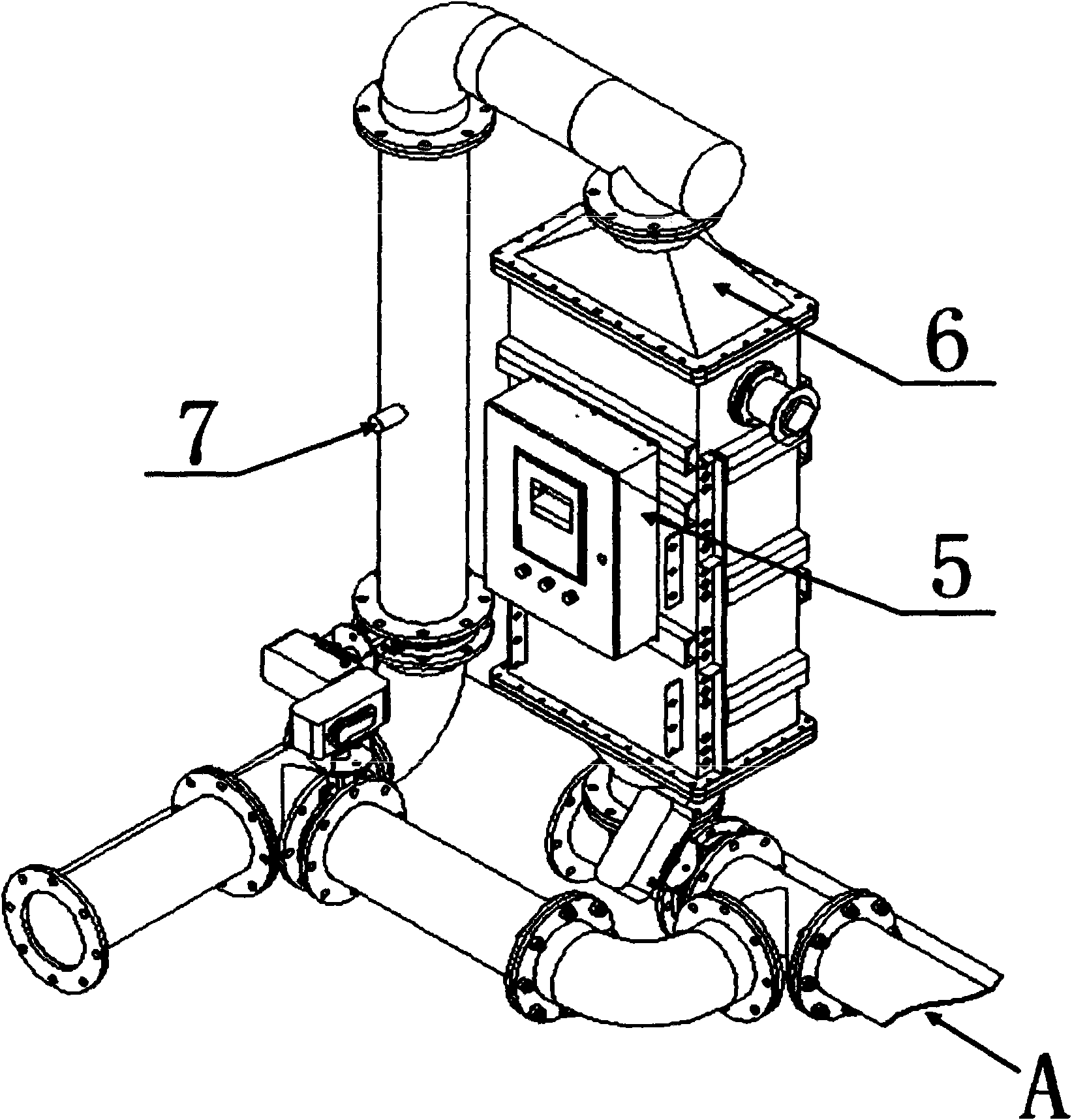

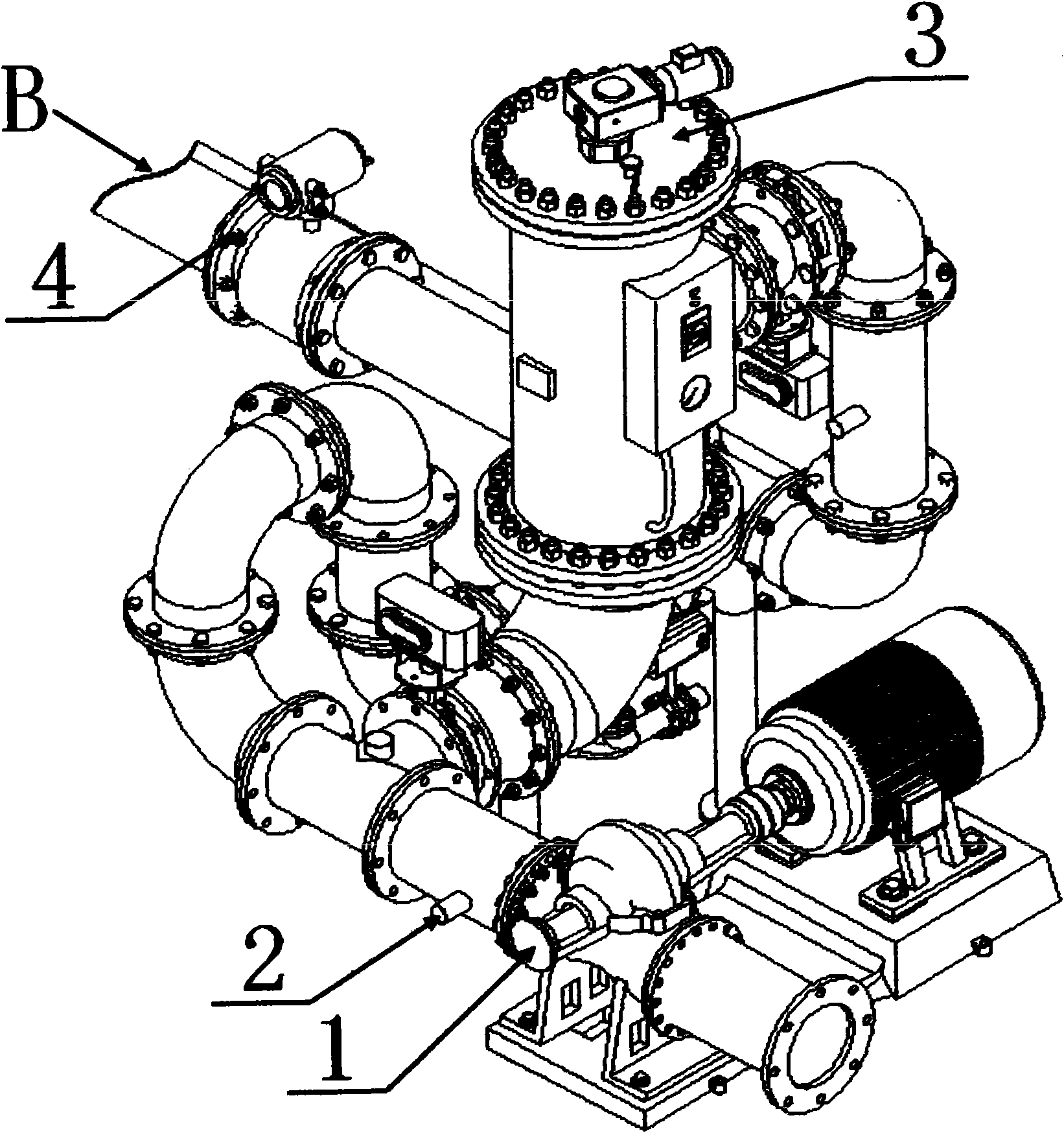

[0059] See figure 1 and figure 2 , figure 1 The pipeline in A is the same as figure 2 The pipes in are integrated at B. A ballast water treatment device, which includes a valve, a ballast water pump 1, a power supply and pipelines, is characterized in that it also includes a filter part 3, a treatment part 6 and a control part 5; the filter part includes a filter unit, a backwash unit and a control unit unit; the processing part is composed of an electrocatalytic unit and an ultrasonic unit; the control part includes an automatic control unit, a monitoring unit and an alarm unit for the system; the monitoring unit includes a conductivity sensor 2, a flow sensor 4 and a total residual oxide sensor 7; the ballast One side of the water pump is connected to the front-end water inlet pipe, and the other side is connected to the rear-end water inlet pipe; the conductivity sensor is installed on the rear-end water inlet pipe; the rear-end water inlet pipe is connected to the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com