Ginsenoside compound in syringa pubescens turca and extraction method and application thereof

A technology of compounds and saponins, which is applied in the field of saponins in Qiaolinghua and its preparation, can solve the problems of incomplete non-saponin components in effective parts, health threats to operators, and low content of active ingredients, so as to achieve controllable quality , less pollution, clear chemical composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

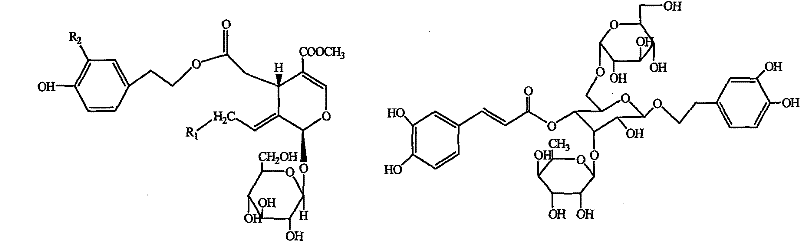

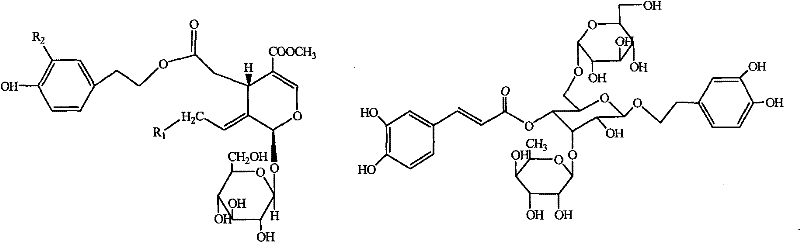

Image

Examples

Embodiment 1

[0028] Take dried and crushed 1Kg of Qiaoling Flower from Funiu Mountain in Western Henan to 40 meshes, add 12Kg of 50% ethanol to soak overnight, heat and reflux for extraction for 4 hours, add 70% ethanol to the residue for reflux extraction twice, each time for 4 hours, combine the extracts, Ethanol was recovered under reduced pressure to obtain 153 g of extract. The ethanol extract is dissolved with 10% ethanol, filtered, and chromatographically separated with 500 grams of macroporous adsorption resin, with ethanol-water (10%, 20%, 30%, 40%, 50%, 60%, 80% and 95 %) gradient elution, each gradient volume is 2.5BV, and the elution flow rate is 1.5BV / h. Collect 40-50% ethanol elution fractions, concentrate under reduced pressure at 50° C., and obtain 18 grams of dry total saponin powder. The contents of oleuropein, 10-hydroxyoleuropein, (8Z)-ligstroside and echinacoside were respectively 24.1%, 7.2%, 6.5%, 45.2% as measured by high performance liquid chromatography, and the t...

Embodiment 2

[0030] Take 2.5Kg of dried and crushed 50-mesh Qiaoling Flower from Funiu Mountain in Western Henan, add 33Kg of 70% ethanol to soak overnight, heat and reflux for extraction for 4 hours, add 70% ethanol to the residue for reflux extraction twice, each time for 4 hours, and combine the extracts , Ethanol was recovered under reduced pressure to obtain 364g of extract. The ethanol extract is dissolved in 20% ethanol, filtered, and chromatographically separated with 1200 grams of macroporous adsorption resin, with ethanol-water (10%, 20%, 30%, 40%, 50%, 60%, 80% and 95% %) gradient elution, each gradient volume is 2.5BV, and the elution flow rate is 1.5BV / h. Collect 40-50% ethanol elution fractions, concentrate under reduced pressure at 55° C., and obtain 42 grams of dry total saponin powder. The contents of oleuropein, 10-hydroxyoleuropein, (8Z)-ligstroside and echinacoside were respectively 22.1%, 7.2%, 5.5%, 42.2% as measured by high performance liquid chromatography, and the ...

Embodiment 3

[0032] Take dried and crushed 5.0Kg of Qiaoling Flowers from Funiu Mountain in Western Henan to 60 mesh, add 60Kg of 60% ethanol to soak overnight, heat and reflux for extraction for 4 hours, add 90% ethanol to the residue for reflux extraction twice, each time for 4 hours, and combine the extracts , Ethanol was recovered under reduced pressure to obtain 705g of extract. The ethanol extract is dissolved with 30% ethanol, filtered, and chromatographically separated with 2500 grams of macroporous adsorption resin, with ethanol-water (10%, 20%, 30%, 40%, 50%, 60%, 80% and 95% %) gradient elution, each gradient volume is 2.5BV, and the elution flow rate is 1.5BV / h. Collect 40-50% ethanol elution fractions, concentrate under reduced pressure at 60° C., and obtain 85 grams of dry total saponin powder. The contents of oleuropein, 10-hydroxyoleuropein, (8Z)-ligstroside and echinacoside were respectively 20.1%, 6.2%, 5.8%, 43.2% as measured by high performance liquid chromatography, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com