Gas treatment method, device and application

A gas treatment and gas technology, which is used in combustible gas purification, combustible gas purification/transformation, condensed non-gaseous material gas purification, etc. It can solve the problems of large measurement distortion, inability of long-term stable operation of the analyzer, and short service cycle. To achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

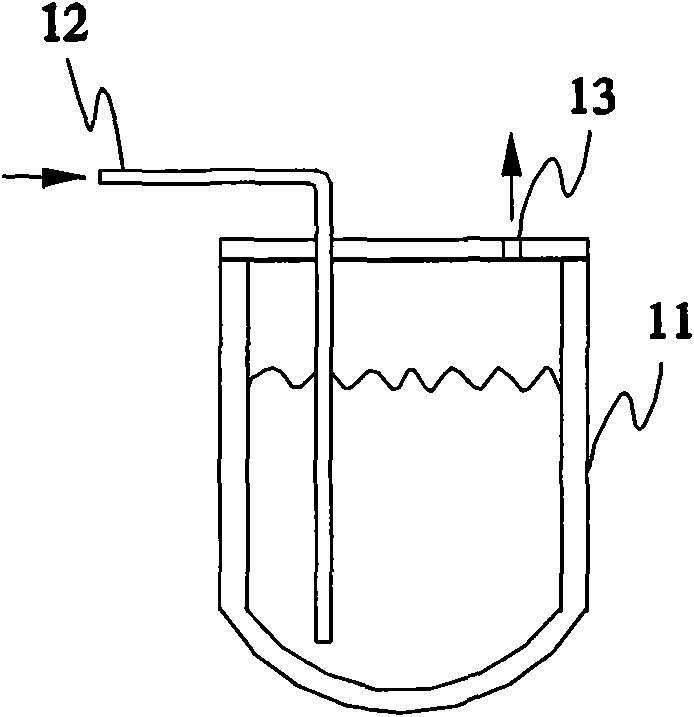

[0041] Such as figure 1 As shown, a gas processing device is used in the coal chemical industry, specifically to treat coke oven gas, so that the H in coke oven gas can be analyzed online. 2 S content, coke oven gas contains tar and hydrogen sulfide. The gas treatment device includes:

[0042] The sealed tank body 11 is made of glass, and phosphoric acid solution is housed in the tank body, and the concentration of phosphoric acid is 80%;

[0043] Intake pipe 12, the position of one open end thereof is lower than the liquid level of phosphoric acid solution; Intake pipe 12 adopts the material that does not adsorb hydrogen sulfide, such as Teflon. The coke oven gas enters the phosphoric acid solution through the inlet pipe 12 and rises in the form of bubbles. During the rising process, the high-concentration phosphoric acid reacts with the tar in the gas to remove the tar in the gas; at the same time, there is no gap between concentrated phosphoric acid and hydrogen sulfide. ...

Embodiment 2

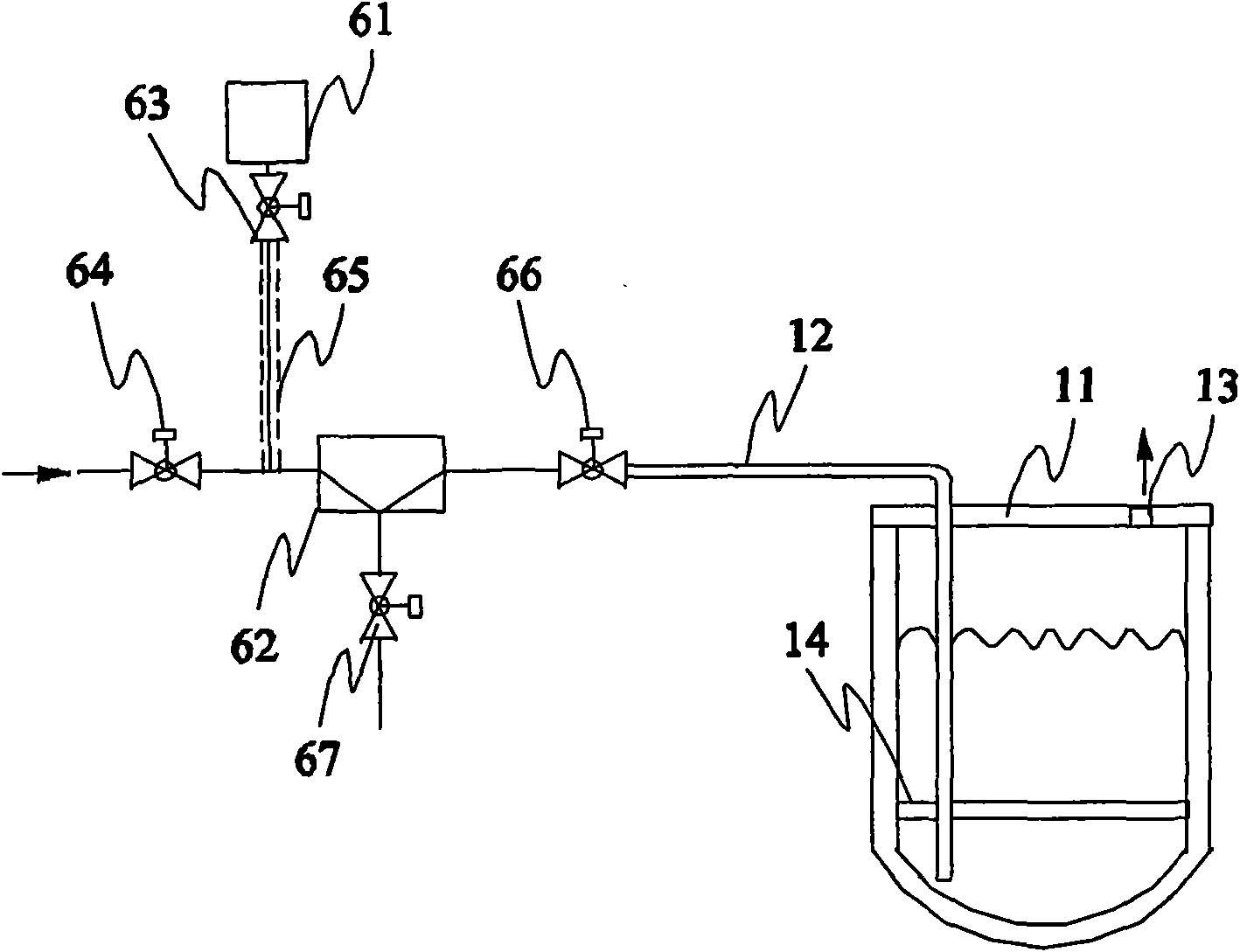

[0050] Such as figure 2 As shown, a gas processing device is used in the coal chemical industry, specifically to treat coke oven gas, so that the H in coke oven gas can be analyzed online. 2 S content, coke oven gas contains tar and hydrogen sulfide. The difference with embodiment 1 is:

[0051] 1. The concentration of phosphoric acid is 85%;

[0052] 2. One end of the inlet pipe 12 is connected to the tank 11 containing phosphoric acid solution, and the other end is connected to the condensing device 62 through the valve 66. The condensing device 62 is connected to the purge gas source 61 through the gas pipeline 65 and the valve 63. The purge gas source provides For gases that do not interact with hydrogen sulfide and phosphoric acid, such as nitrogen, a heating device is provided on the gas pipeline 65; the substance in the condensing device 62 is discharged through the pipeline, and a valve 67 is provided on the pipeline. When the coke oven gas passes through the conde...

Embodiment 3

[0061] Such as image 3 As shown, a gas processing device is used in the iron and steel field, specifically to treat coke oven gas, so that the H in coke oven gas can be analyzed online. 2 S content, coke oven gas contains tar and hydrogen sulfide. The difference with embodiment 2 is:

[0062] 1. The concentration of phosphoric acid in the tank body 11 is 88%;

[0063] 2. A heating device is also installed on the gas source 61. The gas pipeline downstream of the valve 63 is divided into two parts, one part is connected to the pipeline between the valve 64 and the condensing device 62, and the other part is connected to the pipeline between the valve 66 and the condensing device 62;

[0064] 3. The second tank body 21 is also provided with an air intake pipe 22 and an exhaust port 23, and a broken foam net 24 is set in the tank body 21. The concentration of phosphoric acid in the tank body 21 is 94%, and the tank body 11 The exhaust port 13 communicates with the intake pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com