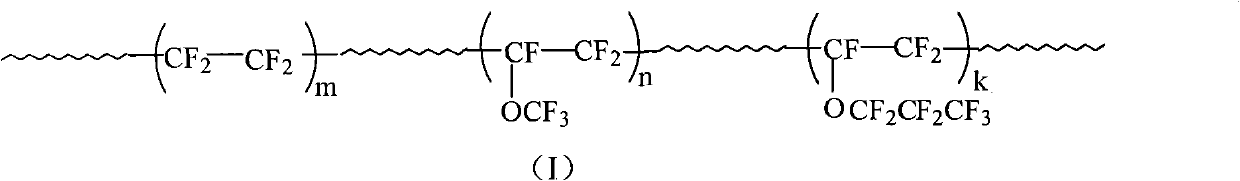

Tetrafluoroethylene triple perfluorinated resin and application thereof as ion-exchange membrane reinforcing material

A technology of tetrafluoroethylene and fluororesin, which is applied in the field of fluoropolymers, can solve the problems that it is difficult to melt and extrude into filaments, it is difficult to achieve, and it affects the thermal stability of polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 23.2g of melamine derivatives with perfluoroalkyl ether chain segments and 185g of distilled water as dispersant / solvent in a 1L high-pressure stainless steel reaction kettle equipped with stirring, heating, and nitrogen feeding devices, and perfluoropropyl vinyl ether 3.02g and 0.2g of benzoyl peroxide, replace the air in the reactor with high-purity nitrogen, introduce 105g of tetrafluoroethylene, 8.76g of perfluoromethyl vinyl ether, heat up to 80°C and stir for 6 hours. After the reaction Cool and deflate to make the pressure inside the kettle become normal pressure, release the product from the discharge pipe, precipitate in a large amount of water, filter to obtain a powder product, wash with distilled water several times, and dry under vacuum at 100°C. Dispersant and water product, liquid separation and recycling.

[0037] The prepared polymer material is tested by Fourier transform infrared and shows that the weight percentage of tetrafluoroethylene is 96.54...

Embodiment 2

[0039]Add 23.2g of melamine derivatives with perfluoroalkyl ether chain segments and 185g of distilled water as dispersant / solvent in a 1L high-pressure stainless steel reaction kettle equipped with stirring, heating, and nitrogen feeding devices, and perfluoropropyl vinyl ether 8.06g and 0.2g of benzoyl peroxide, replace the air in the reactor with high-purity nitrogen, pass through 105g of tetrafluoroethylene, 8.76g of perfluoromethyl vinyl ether, heat up to 80°C and stir for 6h, cool down after the reaction , release gas, make the pressure in the kettle become normal pressure, release the product from the discharge pipe, precipitate in a large amount of water, filter to obtain a powder product, wash with distilled water several times, and dry under vacuum at 100°C. Dispersant and water product, liquid separation and recycling.

[0040] The prepared polymer material is tested by Fourier transform infrared and shows that the weight percentage of tetrafluoroethylene is 95.58% ...

Embodiment 3

[0042] Add 23.2g of melamine derivatives with perfluoroalkyl ether chain segments and 185g of distilled water as dispersant / solvent in a 1L high-pressure stainless steel reaction kettle equipped with stirring, heating, and nitrogen feeding devices, and perfluoropropyl vinyl ether 3.02g and 0.2g of benzoyl peroxide, replace the air in the reactor with high-purity nitrogen, pass through 105g of tetrafluoroethylene, 21.81g of perfluoromethyl vinyl ether, heat up to 80°C and stir for 6h, cool down after the reaction , release gas, make the pressure in the kettle become normal pressure, release the product from the discharge pipe, precipitate in a large amount of water, filter to obtain a powder product, wash with distilled water several times, and dry under vacuum at 100°C. Dispersant and water product, liquid separation and recycling.

[0043] The prepared polymer material is tested by Fourier transform infrared and shows that the weight percentage of tetrafluoroethylene is 93.19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com