Method for synthesizing lauroyl L-carnitine hydrochloride

A technology of lauroyl-L-carnitine and hydrochloride, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as no lauroyl-L-carnitine hydrochloride synthesis report and the like, and achieve a simple method. Easy operation, high yield and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

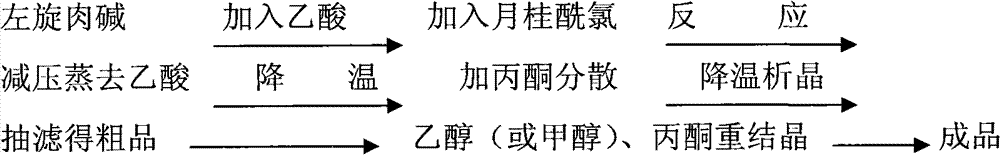

[0023] like figure 1 Shown, a kind of method of synthetic lauroyl-L-carnitine hydrochloride, it comprises the steps:

[0024] 1). Add 161.2g of weighed acetic acid into a four-necked flask (the capacity of the four-necked flask is 1L), and add 161.2g of L-carnitine under stirring to dissolve. After it is completely dissolved, add 221g of lauroyl chloride; then heat up to 75°C Constant temperature for 5 hours; after the reaction is completed, evaporate acetic acid in a vacuum of -0.09Mpa and a temperature below 80°C, add 600g of acetone when the temperature is lowered to 40°C, stir and disperse for 0.5 hours, cool down to below 5°C (including 5°C) for crystallization, and Insulate at 0-5°C for 2 hours; filter, wash the material with acetone, and suction-filter to obtain the crude product, and dry it under vacuum -0.09Mpa, 80-105°C to obtain 372.7g of the crude product of lauroyl-L-carnitine hydrochloride, with a yield of 98.1% .

[0025] 2). Take 200g of the crude product of ...

Embodiment 2

[0033] A method for synthesizing lauroyl L-carnitine hydrochloride, it comprises the steps:

[0034] 1). Add 200g of weighed acetic acid into a four-necked flask, and add 161.2g of L-carnitine to dissolve under stirring. After it is completely dissolved, add 263g of lauroyl chloride dropwise; then raise the temperature to 70°C for 8 hours; Vacuum -0.09Mpa, temperature below 80°C to evaporate acetic acid to precipitate a large number of crystals, cool down to 40°C, add 600g of acetone, fully stir and disperse for 0.5 hours, cool down to below 5°C to crystallize, and keep warm at 0-5°C for 2 hours; filter , to obtain the crude product by suction filtration, and dried at 80° C. with a vacuum of -0.09Mpa to obtain 374 g of the crude product of lauroyl-L-carnitine hydrochloride, with a yield of 98.4%.

[0035] 2). Take 200g of crude lauroyl-L-carnitine hydrochloride, add it into a reactor filled with 420g of anhydrous methanol and stir to dissolve; raise the temperature to 65°C and...

Embodiment 3

[0037] The charge of lauroyl chloride was 218.76g, and the other implementation steps were the same as in Example 2, with a total yield of 92.5%, and the mass content measured under the same high-efficiency liquid phase conditions as in Example 1 was 99.23%. Optical rotation: -25.3° (c=10, H2O), pH value: 2.5, white crystalline powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical rotation | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com