Technique and installation for preparing guaiacol by continuously hydrolyzing diazonium salt of o-amino pheylmethyl ether

A technology of o-anisole and guaiacol, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of enlarged pipeline and material flow, low production efficiency, catalyst change, etc. Efficient mass transfer and heat transfer efficiency, short start and stop time, and reduce the effect of material back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

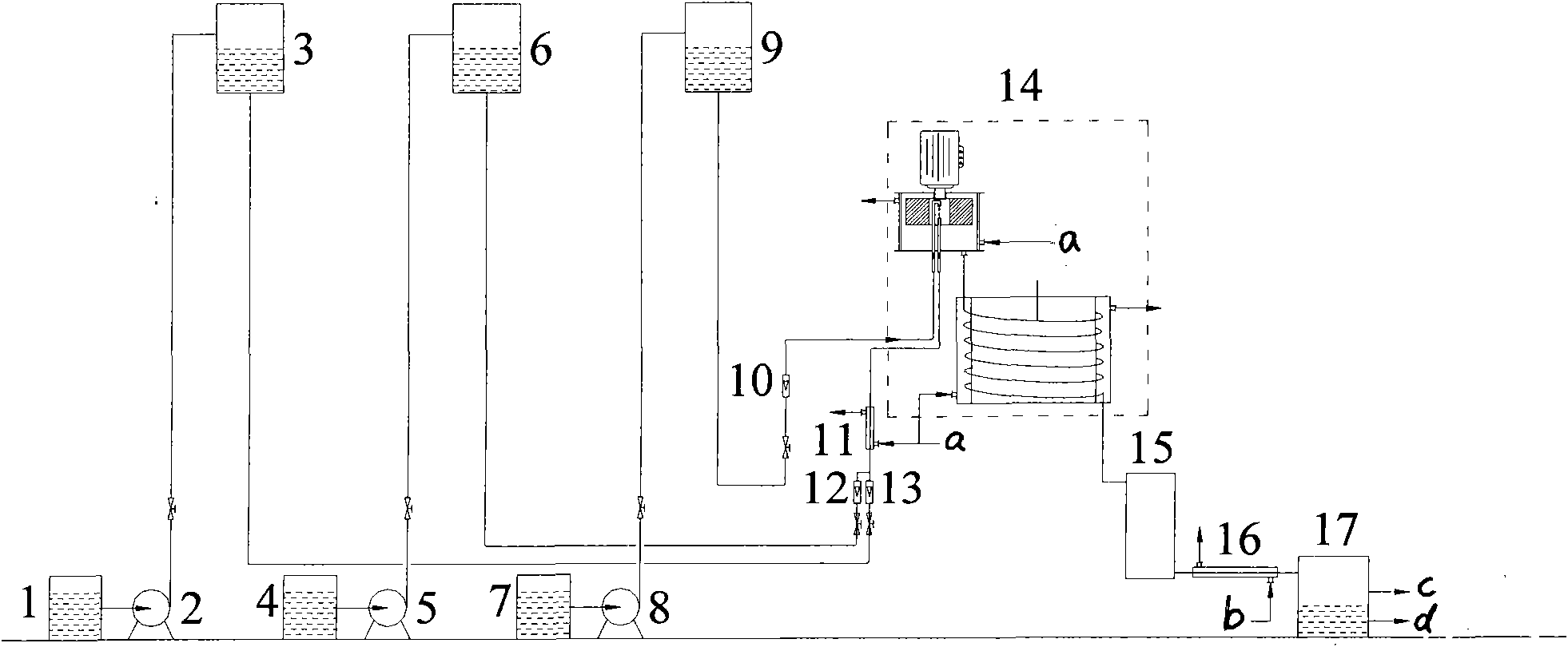

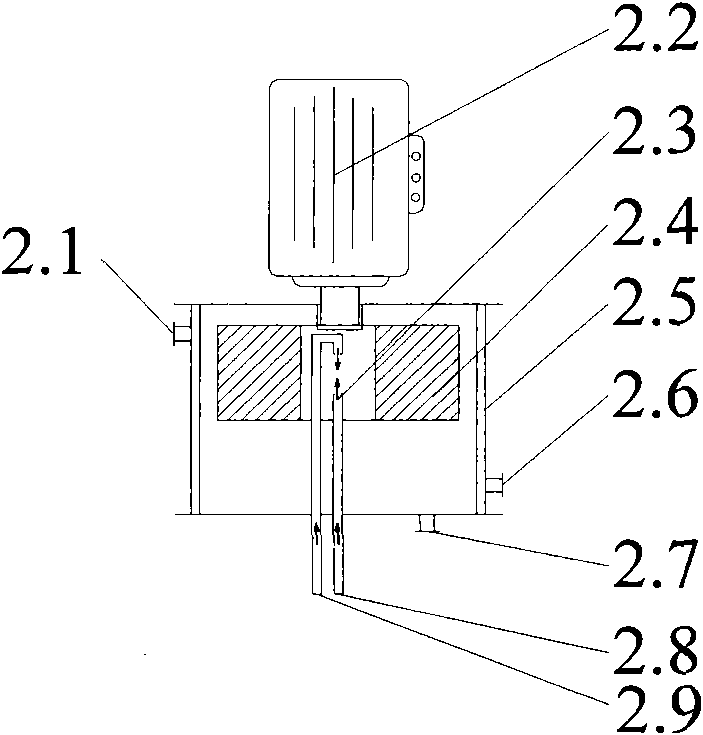

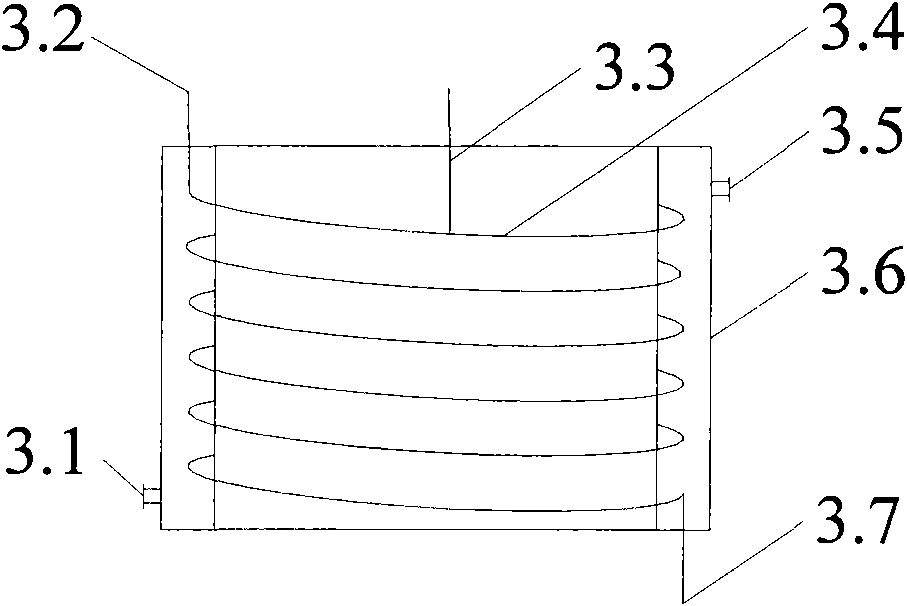

[0046] The diazonium salt solution of anthranilic acid is sent into the diazonium salt solution head tank 9 with pump III8 from the diazonium salt solution storage tank 7, and the hydrolyzate is sent into the head tank with the pump I2 from the hydrolyzate storage tank 1 3, the extractant is sent into the extractant head tank 6 with the pump II 5 from the extractant storage tank 4; the hydrolysis reactor 14 is started, and the rotating speed of the rotary packed bed is adjusted to be 600r / min; to the preheater 11, the rotary packed bed The heating medium is passed into the jacket 2.5 and the sleeve heat exchanger 3.6 respectively; the agitator 15 and the condenser 16 are turned on; Liquid inlet II 2.9, the flow rate of diazonium salt solution is adjusted to 0.5m 3 / h, at the same time, the hydrolyzate in the hydrolyzate head tank 3 and the extractant in the extractant head tank 6 pass through the liquid flow meters 13 and 12 respectively, mix first, and then pass through the p...

Embodiment 2

[0048] Under the operation of Example 1, the rotating speed of the rotating packed bed is adjusted to be 600r / min; the flow rate of the diazonium salt solution is adjusted to 1.0m 3 / h, the flow rate of the hydrolyzate is adjusted to 0.5m 3 / h, the flow of toluene is adjusted to 0.2m 3 / h; the mixture of hydrolyzate and toluene is heated to 100°C, and the temperature of the liquid at the outlet of the impinging flow rotating packed bed is heated to 105°C; the total residence time of the reactants flowing through the hydrolysis reactor is adjusted to 7.0min. The yield of guaiacol was 87.5%.

Embodiment 3

[0050] Under the operation of Example 1, the rotating speed of the rotating packed bed is adjusted to be 1200r / min; the flow rate of the diazonium salt solution is adjusted to 1.5m 3 / h, the flow rate of the hydrolyzate is adjusted to 0.8m 3 / h, the flow of toluene is adjusted to 0.4m 3 / h; the total residence time of the reactant flow through the hydrolysis reactor is adjusted to 6.2min. The yield of guaiacol was 90.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com