Method for preparing nanometer composite film consisting of titanium dioxide nanotube and nanocrystalline

A titanium dioxide and nanocomposite technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of low electron transport capacity of nanocrystals, difficult to further improve the specific surface area of nanotubes, etc., and achieve controllable film structure and low cost. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

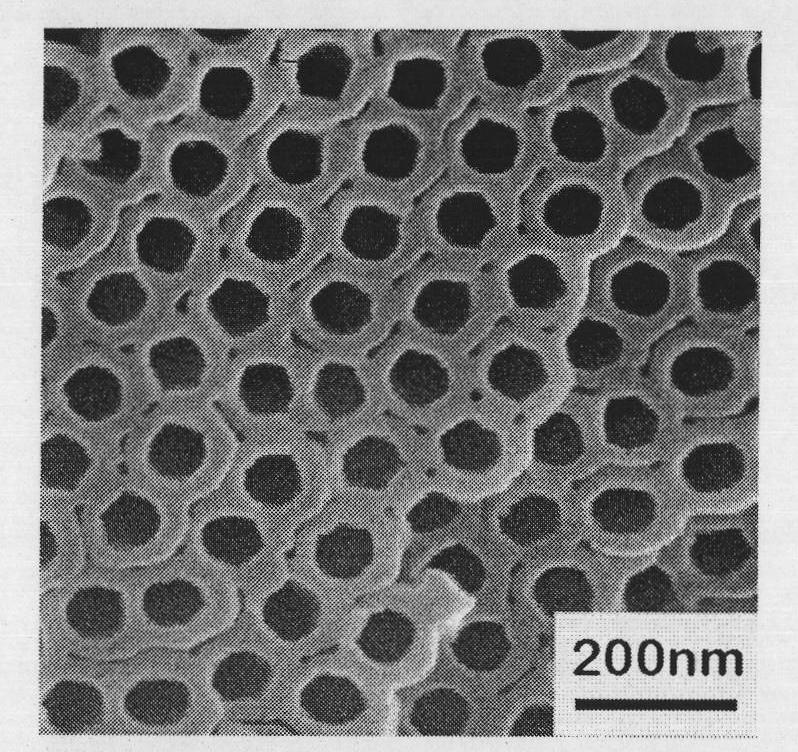

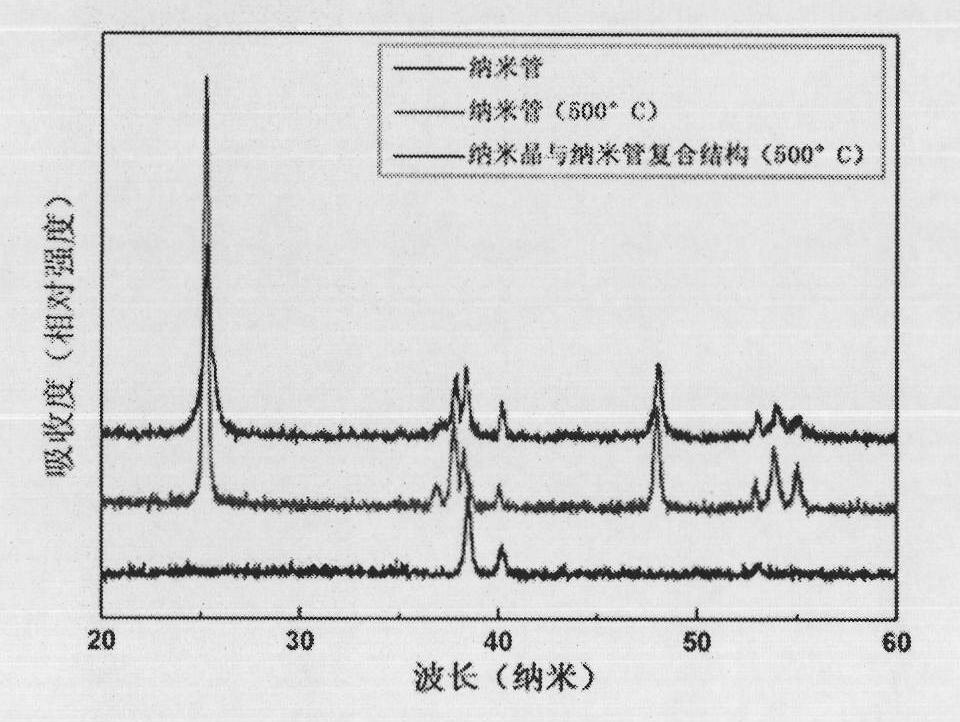

[0014] Put the titanium metal sheet in 0.4% NH 4 F In ethylene glycol solution, applied voltage 80V, reacted for 9h, took out the sample and washed it with absolute ethanol, N 2 Blow dry to get TiO perpendicular to the titanium sheet substrate 2 nanotube film. At room temperature, dissolve 1.58 g of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polymer in 15 ml of absolute ethanol, stir and drop 0.2 ml of acetylacetone and 7 ml of n-butyl titanate after completely dissolving ester, and then added 1ml of concentrated hydrochloric acid and 0.2ml of deionized water; stirred at room temperature for 0.5 hours to obtain a titanium dioxide precursor sol. TiO prepared by anodic oxidation method by immersion 2 The nanotube film is immersed in the titanium dioxide precursor sol, and the surface is washed with absolute ethanol after the gel is formed. Insulate at 500°C for 2.5 hours, and cool to room temperature naturally. In this way, a nanocomposite film composed of ti...

Embodiment 2

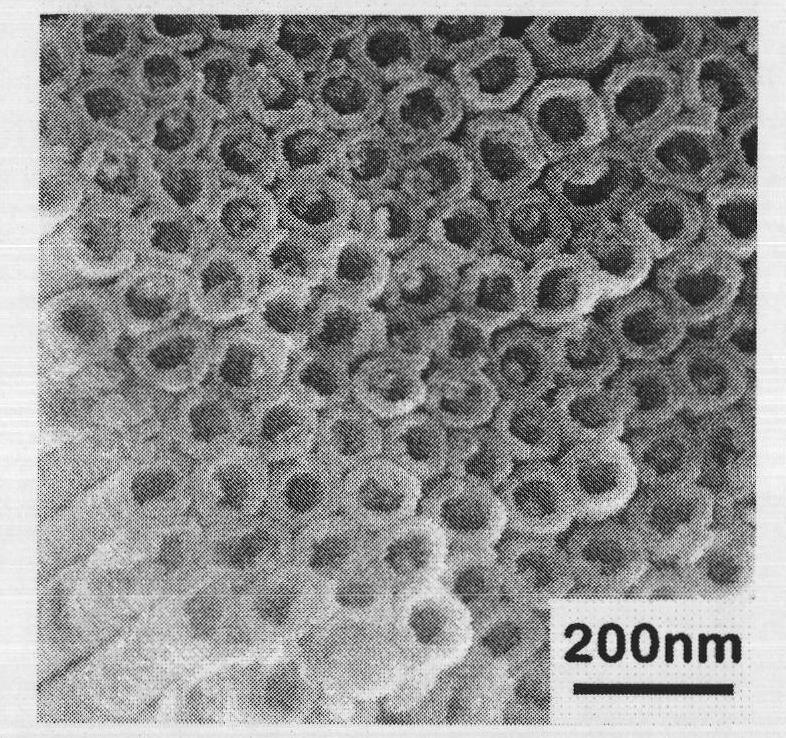

[0016] Put the titanium metal sheet in the HF aqueous solution with a mass concentration of 0.2%, apply a voltage of 20V, and react for 0.25h, take out the sample and rinse it with absolute ethanol, N 2 Blow dry to obtain a TiO with a height perpendicular to the titanium sheet substrate with a thickness of about 0.35 microns 2 nanotube film. At room temperature, dissolve 3 grams of polystyrene-polyoxyethylene block polymer in 25 ml of absolute ethanol, and after complete dissolution, add 1.0 ml of acetylacetone and 15 ml of isopropyl titanate dropwise, and then add 3 ml of Concentrated hydrochloric acid and 1ml deionized water; stirred at room temperature for 6 hours to obtain a titanium precursor sol. TiO prepared by anodic oxidation method by immersion 2 The nanotube film is immersed in the titanium dioxide precursor sol, and the surface is washed with absolute ethanol after the gel is formed. Keep the temperature at 550° C. for 1 hour, and cool to room temperature natura...

Embodiment 3

[0018] Put the titanium metal sheet in 0.8% NH 4 F In ethylene glycol solution, apply a voltage of 60V, react for 18h, take out the sample and rinse it with absolute ethanol, N 2 Blow dry to obtain TiO with a height perpendicular to the titanium sheet substrate 2 nanotube film. At room temperature, 1 gram of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock polymer was dissolved in 10 ml of absolute ethanol, and after complete dissolution, 0.2 ml of acetylacetone and 5 ml of ethyl titanate were added dropwise, Then add 1 ml of concentrated hydrochloric acid and 0.2 ml of deionized water; stir at room temperature for 0.5 hours to obtain a titanium precursor sol. TiO prepared by anodic oxidation method by immersion 2 The nanotube film is immersed in the titanium precursor, and the surface is rinsed with absolute ethanol after the gel is formed. Insulate at a temperature of 450°C for 3 hours, and cool to room temperature naturally. In this way, a nanocomposite film c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com