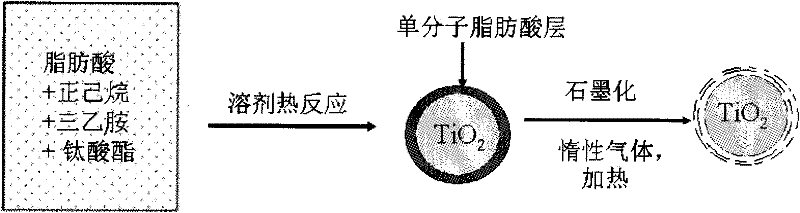

TiO2 @ graphitized carbon nuclear shell compound photocatalyst with high visible light catalytic activity and preparation method thereof

A high catalytic activity, titanium dioxide technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of small specific surface area and large particles, and achieve large specific surface area, small particle size, The effect of rapid catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

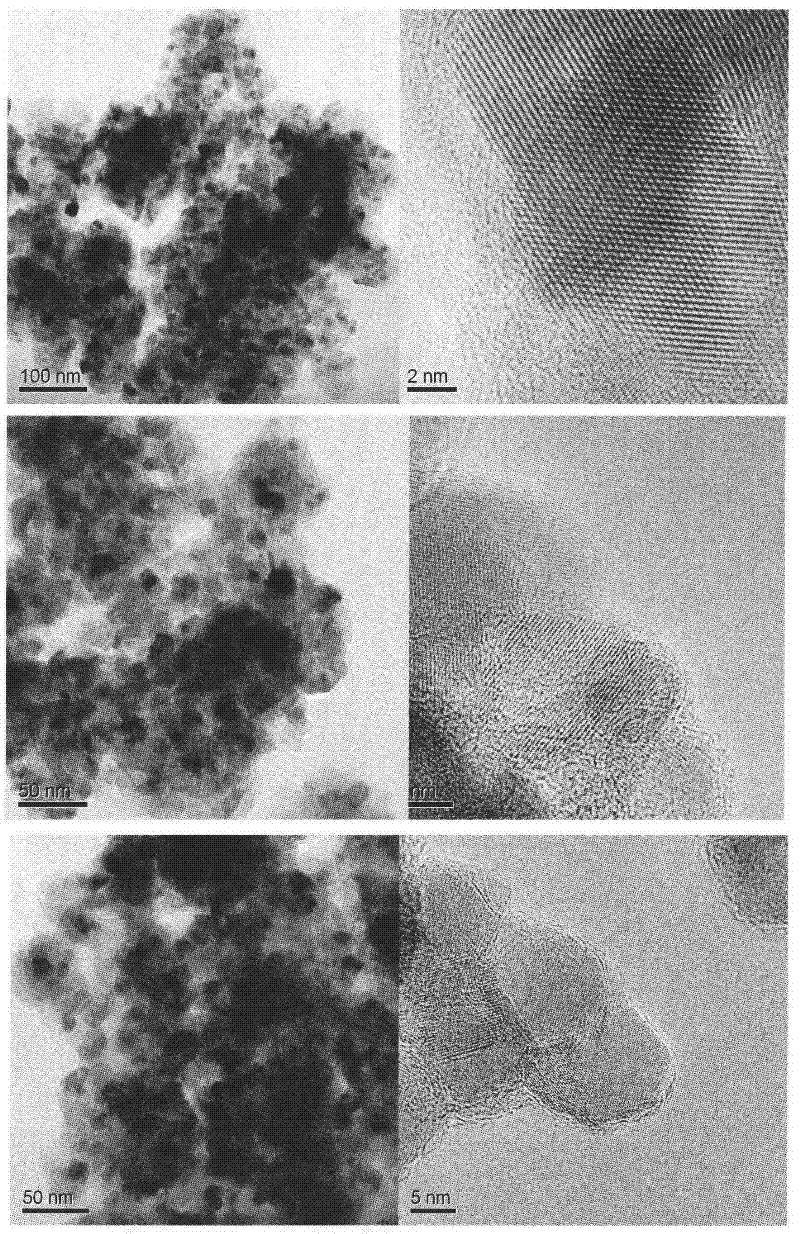

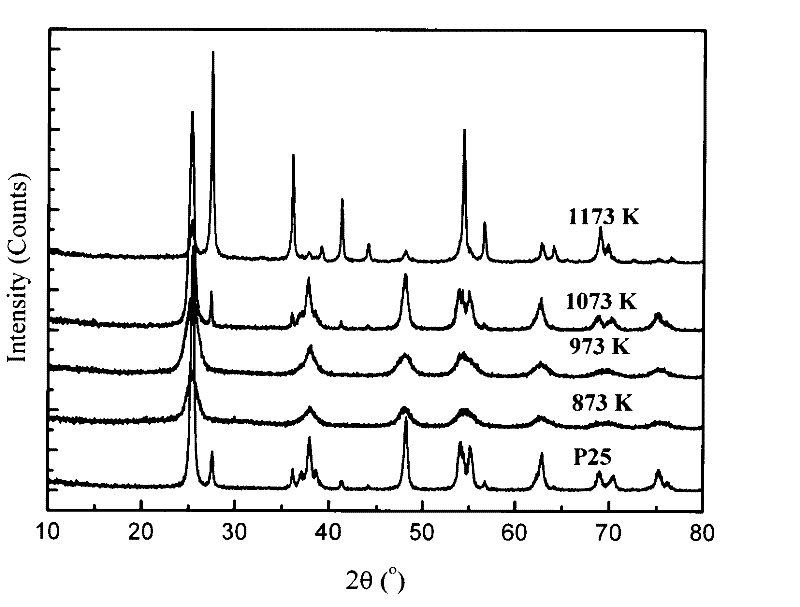

Embodiment 1

[0037] Mix 10ml triethylamine, 30ml oleic acid, 40ml cyclohexane, and 2ml n-butyl titanate, add 100ml hydrothermal kettle, keep warm at 165°C for 24h, cool, centrifuge and wash 5 times with absolute ethanol, 80°C Vacuum drying for 12 hours, and then under the protection of high-purity argon, heat treatment at 500°C for 5 hours to obtain a titanium dioxide graphitized carbon core-shell composite photocatalyst. X-ray diffraction test shows that the crystal form of titanium dioxide is 100% anatase, and its crystal grain is about 3.4nm according to Scherrer's formula.

Embodiment 2

[0039] Mix 10ml triethylamine, 30ml oleic acid, 40ml cyclohexane, and 2ml n-butyl titanate, add 100ml hydrothermal kettle, keep warm at 165°C for 24h, cool, centrifuge and wash 5 times with absolute ethanol, 80°C Vacuum drying for 12 hours, and then under the protection of high-purity argon, heat treatment at 600°C for 5 hours to obtain a titanium dioxide graphitized carbon core-shell composite photocatalyst. X-ray diffraction test shows that the crystal form of titanium dioxide is 100% anatase, and the crystal grain is about 5.8nm according to Scherrer's formula.

Embodiment 3

[0041] Mix 10ml triethylamine, 30ml oleic acid, 40ml cyclohexane, and 2ml n-butyl titanate, add 100ml hydrothermal kettle, keep warm at 165°C for 24h, cool, centrifuge and wash 5 times with absolute ethanol, 80°C Vacuum drying for 12 hours, and then under the protection of high-purity argon, heat treatment at 700°C for 5 hours to obtain a titanium dioxide graphitized carbon core-shell composite photocatalyst. X-ray diffraction test shows that the crystal form of titanium dioxide is 100% anatase, and its crystal grain is about 9.8nm according to Scherrer's formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com