Heat accumulating type food heat-preservation device with metal porous structure

A technology of porous metal and thermal insulation devices, applied in heating devices, household appliances, tableware, etc., can solve the problems of reduced device life, local temperature rise, low thermal conductivity, etc., to reduce contact thermal resistance, accelerate melting, Enhance the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

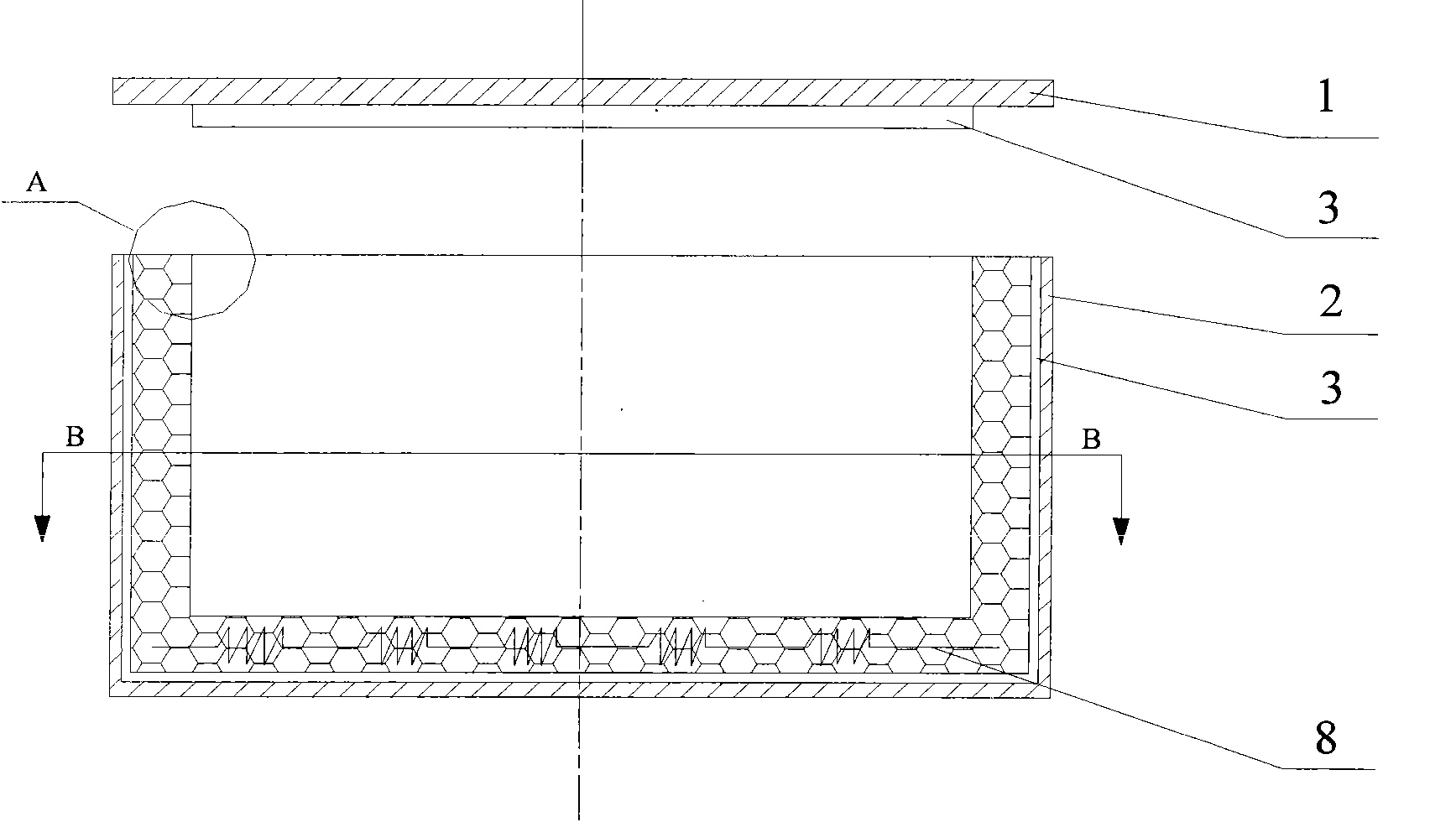

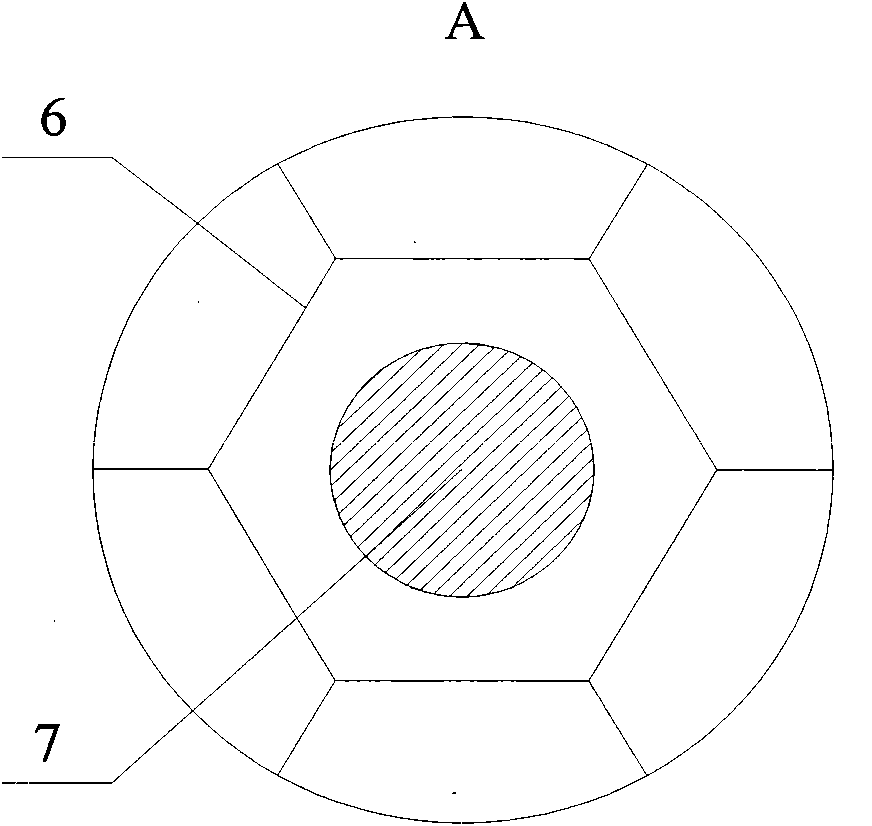

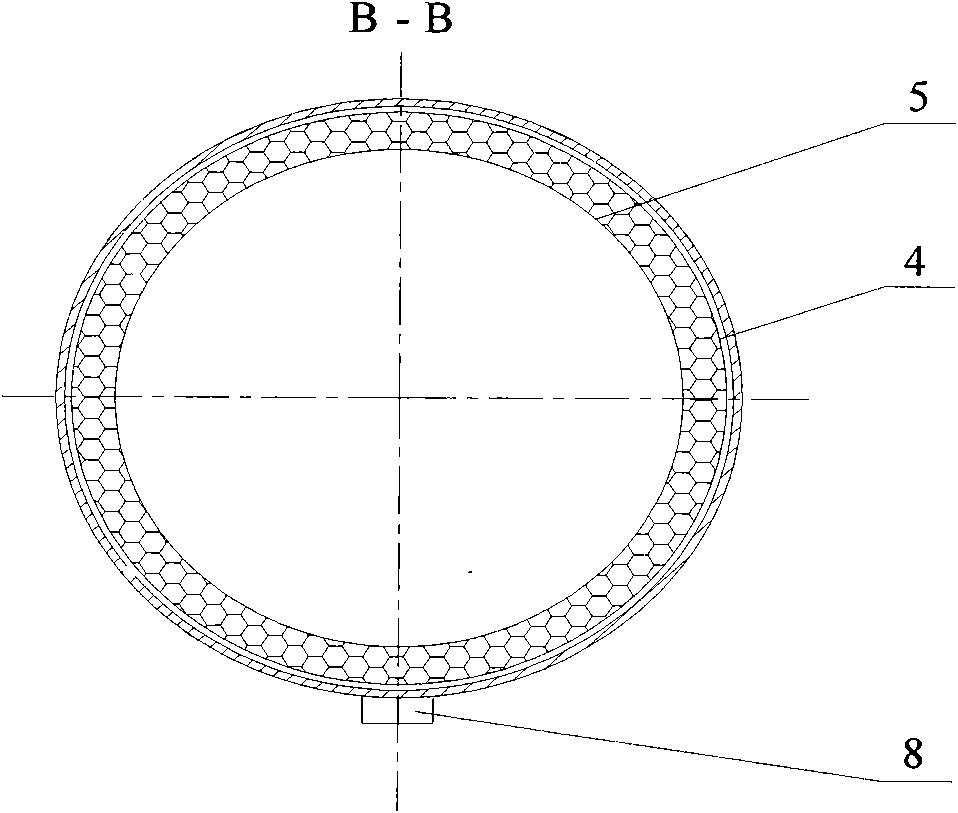

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , figure 2 and image 3 , the present invention includes an outer shell 2, an inner shell, a top cover 1, and a vacuum layer 3 formed by the outer shell 2 and the inner shell. Vacuum layer, to prevent heat from escaping outwards, the thickness of the vacuum layer is between 3mm ~ 5mm, said inner shell includes outer wall 4 and inner wall 5 made of aluminum, copper or alloy materials and the inner wall formed between the outer wall cavity. The inner side of the shell 2 and the outer surface of the inner wall 5 are plated with silver, and the cavity formed between the outer wall 4 and the inner wall 5 is filled with through-hole metal foam 6 made of aluminum, copper or alloy materials, and the through-hole metal foam 6 is sintered On the inner wall 5, the porosity of the through-hole metal foam is 0.50-0.95 (the percentage of the pore v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com