Magnesium-containing catalytic material for anode of solid oxide fuel cell, preparation and application thereof

A technology of solid oxides and catalytic materials, applied in the direction of metal/metal oxide/metal hydroxide catalysts, battery electrodes, physical/chemical process catalysts, etc., can solve the problems of low anode activity, reduced electrode activity, and electrode loss of activity, etc. problems, to achieve the effect of improving interface contact, reducing polarization resistance, and improving electrode activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

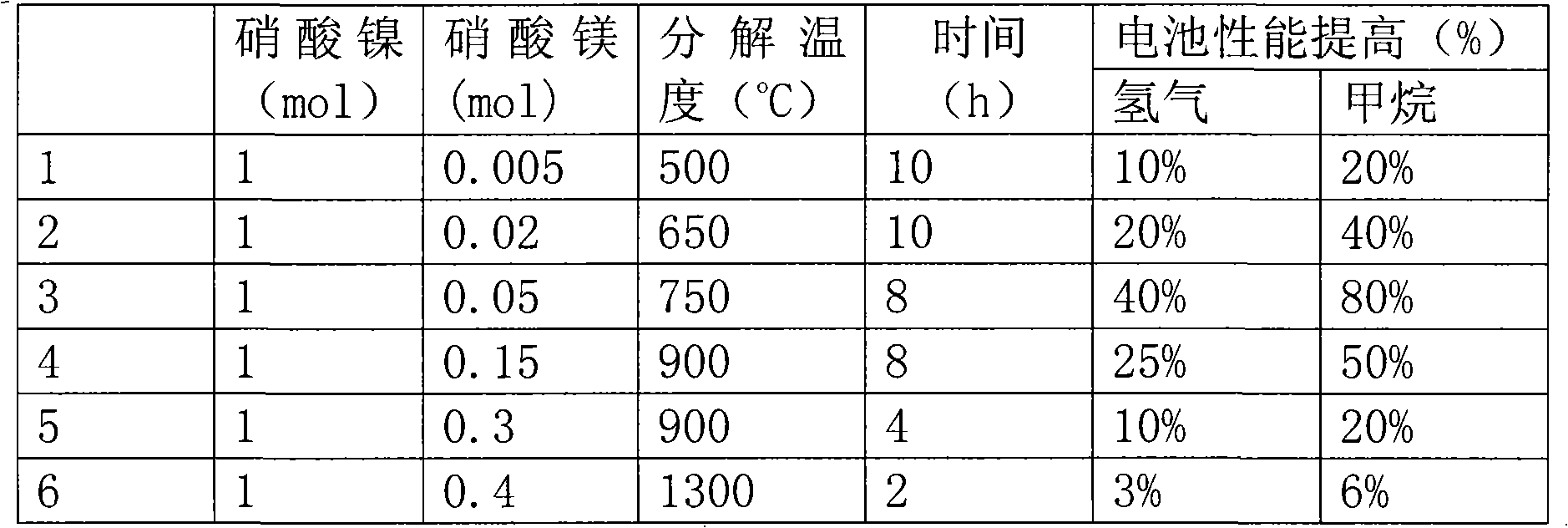

[0015] Effects of Magnesium-modified Nickel Oxide Catalytic Materials on the Performance of Solid Oxide Fuel Cells by Nitrate Decomposition

[0016] A nitrate decomposition method is used to co-decompose the mixture of magnesium nitrate and nickel nitrate between 500°C and 1300°C to obtain a magnesium-modified nickel oxide electrode catalyst material.

[0017] Magnesium-modified nickel oxide is selected as the anode catalyst material and yttrium oxide-stabilized zirconia (8YSZ, the molar content of yttrium oxide in YSZ is 8%) is mixed (by weight ratio 50:50) to prepare the anode, and the yttrium oxide-stabilized zirconia (8YSZ) as the electrolyte, and LSM-YSZ (50:50 by weight) as the cathode to prepare the battery.

[0018] Test conditions: at 800°C, hydrogen (80ml / min) or methane (20ml / min) is used as the anode fuel gas, and oxygen (40ml / min) is used as the cathode gas.

[0019] Table 1

[0020]

[0021] It can be seen from Table 1 that the battery performance gradually ...

Embodiment 2

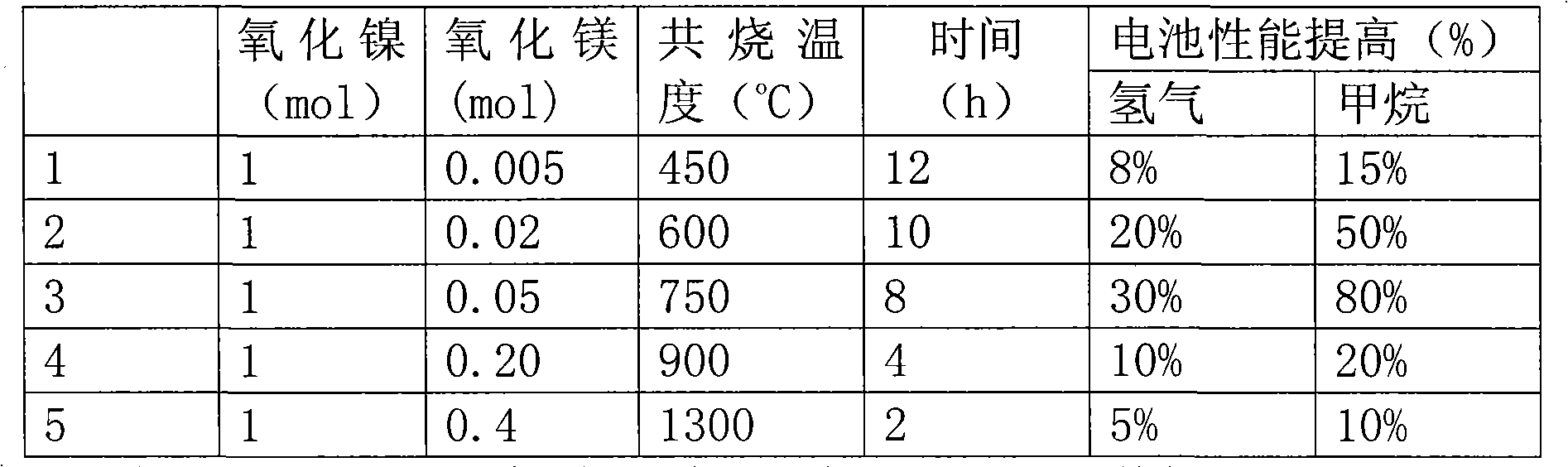

[0023] Effect of Modified Nickel Oxide Using Magnesium Oxide Used in Solid Oxide Fuel Cells on Battery Performance

[0024] The anode catalyst material is obtained by mixing different proportions of magnesium oxide and nickel oxide and then calcining at 450°C-1300°C. A battery was prepared using the anode catalyst material, and the battery preparation method and test conditions were the same as in Example 1. A conventional Ni-YSZ anode battery was used as a comparison battery.

[0025] Table 2

[0026]

[0027] It can be seen from Table 2 that when magnesium oxide is used to modify nickel oxide for solid oxide fuel cells, the battery performance will also be greatly improved.

Embodiment 3

[0029] Effect of directly mixing nickel oxide and magnesium oxide in solid oxide fuel cells on battery performance

[0030] Directly ball mill nickel oxide and magnesium oxide for 10 hours, and mix them uniformly to obtain the anode catalyst material. The magnesium-modified nickel oxide (Ni:Mg=1:0.1) synthesized by this method is selected as the anode catalyst material. (8YSZ, the molar content of yttrium oxide in YSZ is 8%) mixed (50:50 by weight) to prepare anode, yttria-stabilized zirconia (8YSZ) as electrolyte, LSM-YSZ (50:50 by weight) as The cathode prepares the battery. Taking the traditional Ni-YSZ anode battery as a comparison battery, when hydrogen is used as the fuel gas, the performance of the magnesium-modified battery is compared with the performance of the traditional Ni-YSZ anode battery, and the battery performance is improved by about 20% when operating at 800 °C. When methane is used as the fuel gas, the performance of the magnesium-modified nickel oxide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com