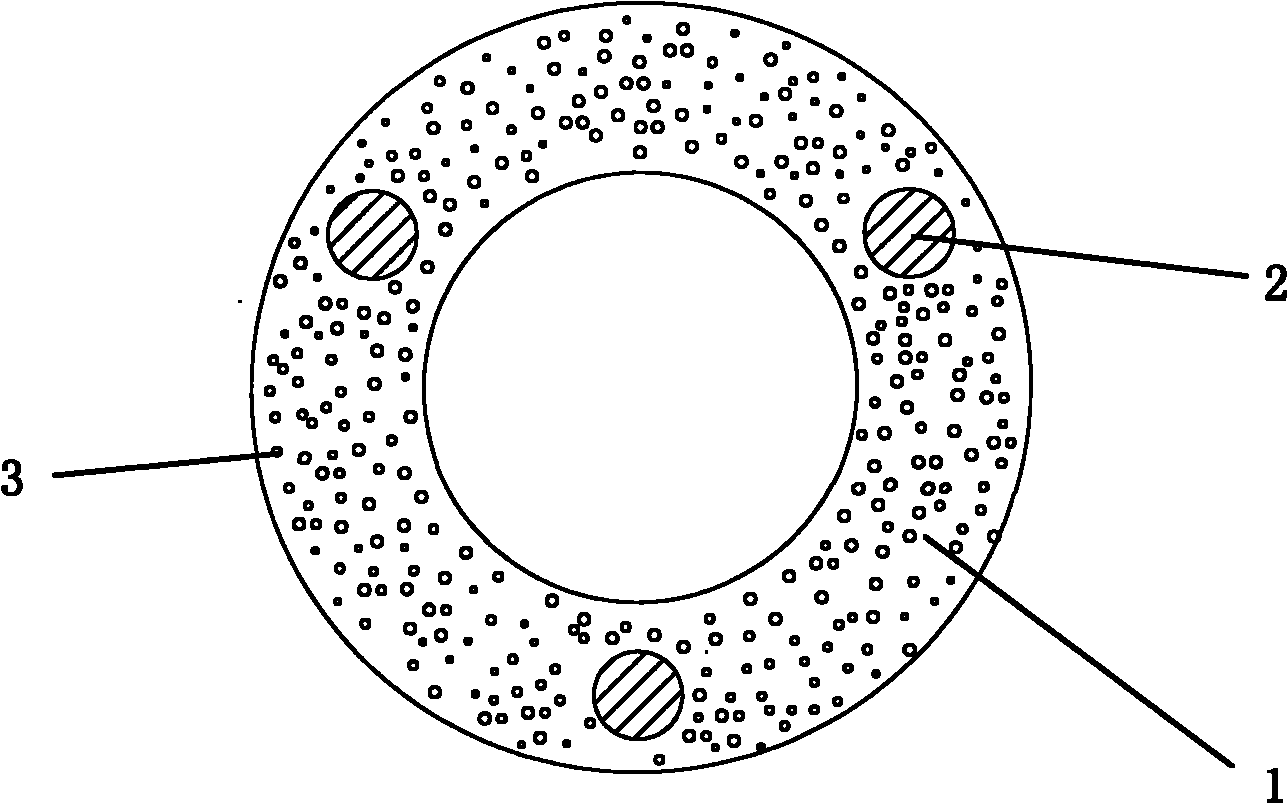

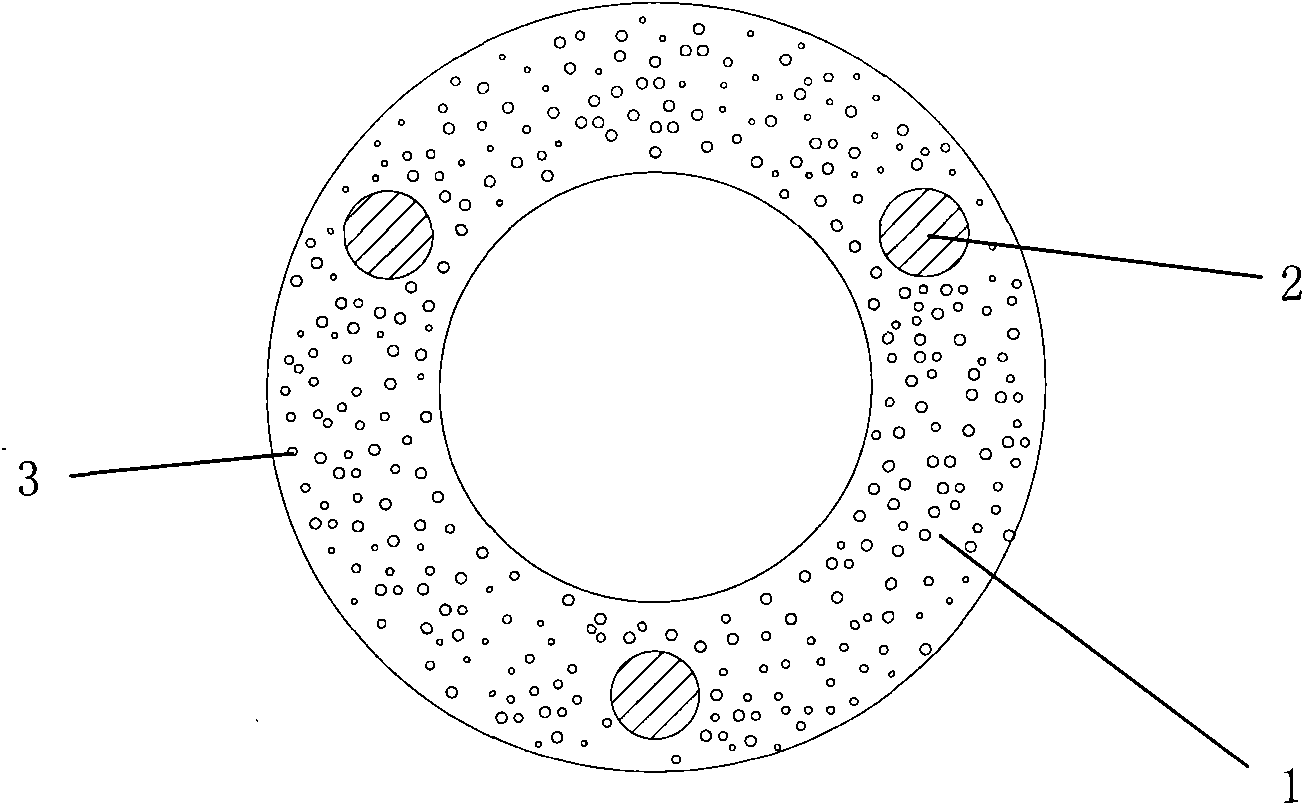

Composite hollow fiber membrane and preparation method thereof

A fiber membrane and hollow technology, which is applied in the field of composite hollow fiber membrane and its preparation, can solve the problems of limited application field and difficult maintenance, and achieve the effects of tight intermolecular bonding, enhanced strength, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

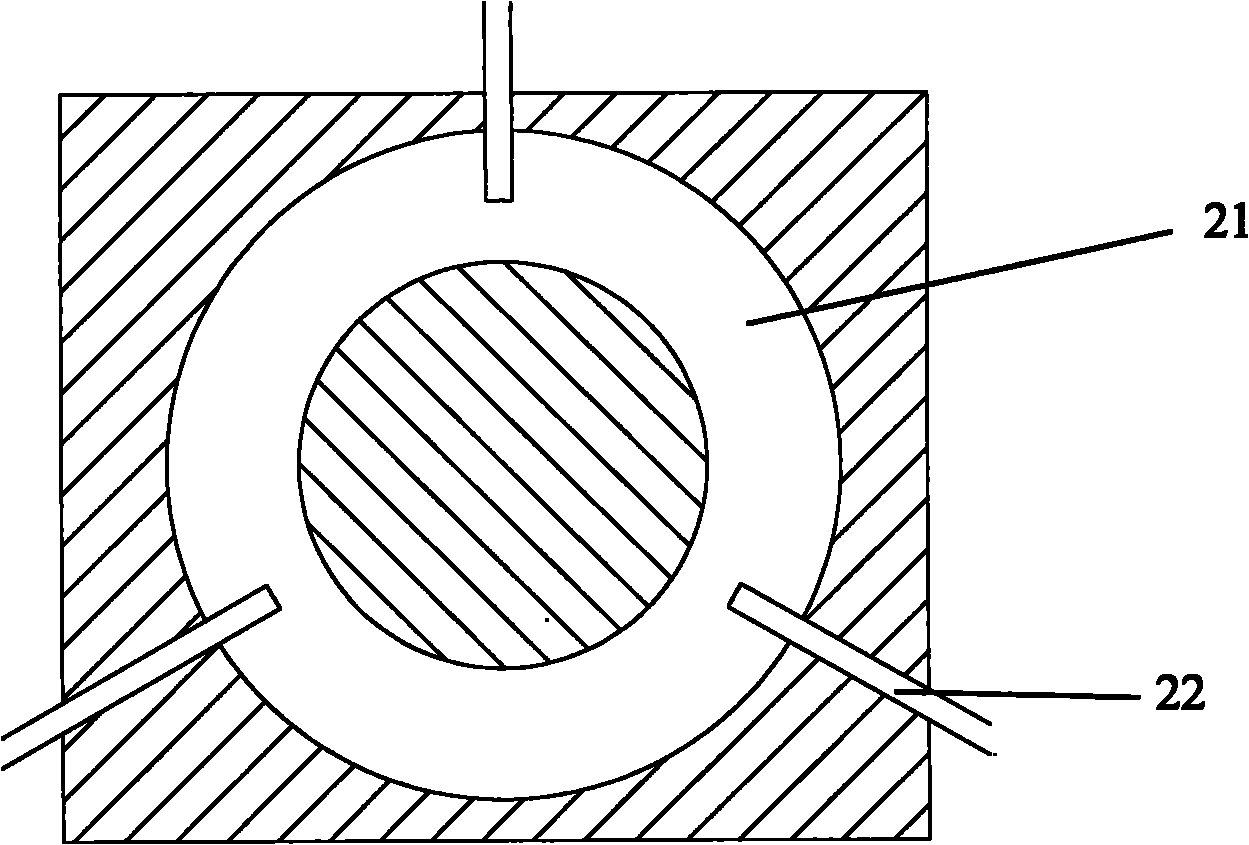

Method used

Image

Examples

Embodiment 1

[0044] Pore-forming component: polyphenylene sulfide, pore-forming agent: copolyester PET, support component: polyphenylene sulfide

[0045] Using a buss mixer, 9 kg of polyphenylene sulfide and 1 kg of copolyester PET were blended and granulated at 300° C. to prepare 10 kg of pore-forming components. Take 1 kg of pure polyphenylene sulfide as the supporting component and the pore-forming component to extrude on a composite spinning machine at 310°C, and compound at 315°C to prepare a composite polyphenylene sulfide with a composite ratio of 20:80 between the supporting component and the pore-forming component. Phenylsulfide hollow fibers. The fiber was stretched and set, the stretching temperature was 80°C, the draw ratio was 4.5 times, the stretching speed was 500m / min, and the setting temperature was 190°C; then the fiber was treated in 20% sodium hydroxide lye at 90°C for 24 Hours to dissolve the water-soluble PET in the pore-forming component to form a hollow fiber membr...

Embodiment 2

[0047] Pore-forming component: polyphenylene sulfide, pore-forming agent: silica, support component: polyphenylene sulfide

[0048] The silicon dioxide powder is selected to have a particle diameter of 5nm-200nm, preferably 5nm-50nm. Using a twin-screw extruder, 9 kg of polyphenylene sulfide and 1 kg of silicon dioxide were blended and granulated at 290° C. to prepare 10 kg of a pore-forming component. Take 1 kg of pure polyphenylene sulfide as the support component and the pore-forming component to extrude on a composite spinning machine at 315° C., and compound at 320° C. to prepare a composite polyphenylene sulfide with a support component and pore-forming component composite ratio of 10:90. Phenylsulfide hollow fibers. The fiber is stretched and set, the stretching temperature is 90°C, the draw ratio is 3.5 times, the stretching speed is 600m / min, and the setting temperature is 200°C; then the fiber is soaked in 10% potassium hydroxide solution at room temperature for 8 h...

Embodiment 3

[0050] Pore-forming component: polyphenylene sulfide, pore-forming agent: calcium carbonate, supporting component: polyphenylene sulfide;

[0051] The calcium carbonate powder is selected to have a particle diameter of 5nm to 200nm, preferably 5nm to 50nm. Using a buss screw, 9 kg of polyphenylene sulfide and 1 kg of calcium carbonate were blended and granulated at 300° C. to prepare 10 kg of a pore-forming component. Take 1 kg of pure polyphenylene sulfide as the supporting component and the pore-forming component to extrude on a composite spinning machine at 315 ° C, and compound at 325 ° C to prepare a composite polyphenylene sulfide with a composite ratio of supporting component and pore-forming component of 30:70. Phenylsulfide hollow fibers. The fiber is subjected to stretching and setting treatment, the stretching temperature is 90°C, the stretching ratio is 3 times, the stretching speed is 10m / min, and the setting temperature is 200°C; then the fiber is soaked in 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface aperture | aaaaa | aaaaa |

| Membrane inner diameter | aaaaa | aaaaa |

| Surface aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com