Processing technology of printed circuit board

A technology of printed circuit board and processing technology, which is applied in the directions of secondary processing of printed circuit, multi-layer circuit manufacturing, coating of non-metallic protective layer, etc., which can solve the problems of damaging the solder mask layer, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

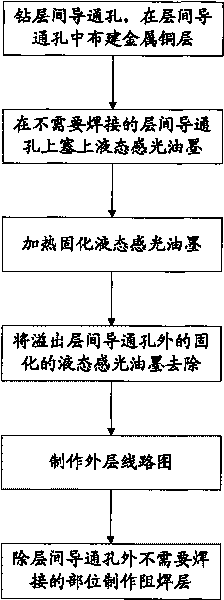

[0024] see figure 1 As shown in the process, this embodiment provides a printed circuit board processing technology, and the printed circuit board processing technology includes the following steps in sequence:

[0025] A. Drill via holes, and build a metal copper layer in the via holes. The specific order is: drilling, bulking, holeization, copper sinking, degreasing, pickling, and copper plating;

[0026] B. Plug liquid photosensitive ink on the via holes that do not need to be soldered. The specific order is as follows: Prepare an aluminum plate with holes. The holes on the aluminum plate correspond to the holes that need to be plugged in the circuit design. Cover the aluminum plate to the circuit. Align the corresponding holes on the board, and use silk screen printing to plug the via holes with ink;

[0027] C. Heating and curing the liquid photosensitive ink in the via hole; specifically: first use 80°C to heat the solder resist in the via hole for 60 minutes, then use ...

Embodiment 2

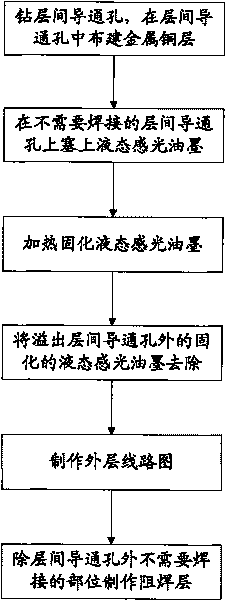

[0034] This embodiment provides a printed circuit board processing technology, which sequentially includes the following steps:

[0035] A. Drill via holes, and build a metal copper layer in the via holes, the specific order is: drilling, sinking copper, and copper plating;

[0036] B. Make the outer layer circuit, specifically in order: film sticking, exposure and development, and copper etching.

[0037] C. Plug liquid photosensitive ink on the via holes that do not need to be soldered, and use a small hollow tube to pour photosensitive ink into each via hole that needs to be plugged;

[0038] D. Heating and curing the liquid photosensitive ink in the via hole; specifically: heating the solder resist in the via hole at 150°C for 60 minutes;

[0039] E. Shovel and scrape off the solidified liquid photosensitive ink overflowing the via hole; the specific sequence is: use a 600-mesh brush roller grinding plate;

[0040] F. Make a liquid photosensitive ink solder resist layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com