Method for producing low-temperature impact resistance high-strength nodular cast iron

A low-temperature impact-resistant, nodular cast iron technology is applied in the direction of improving process efficiency and can solve problems such as insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] 1. Raw material preparation

[0039] 1. Raw iron: High-purity pig iron purchased from Shanxi Province is used.

[0040] 2. Scrap steel: High-quality medium and low-carbon scrap steel must be derusted before use.

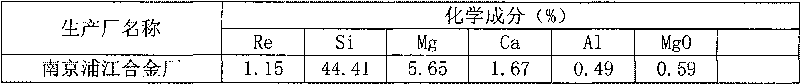

[0041] 3. Nodulizer: Low Re and low Mg alloy produced by Nanjing Pujiang Alloy Factory.

[0042] 4. Inoculant: Silicon-barium alloy produced by Qufu Foundry Material Factory is used for inoculation in the bag.

[0043] 5. Desulfurizer: The deep desulfurizer produced by Yantai Shenglida Company is used.

[0044] 6. Carburizer, covering agent and slag collecting agent adopt existing materials.

[0045] 2. Material requirements: grade QT450-10.

[0046] 3. The achieved chemical composition ω (%):

[0047] C 3.5~3.9%, Si 1.8%~2.5%, Mn≤0.2%, P≤0.05%, S≤0.015%, Mg0.03~0.06%, Re 0.01~0.03%, Ti≤0.055%, Cu 0.15- 0.50%, the balance is Te.

[0048] Fourth, the achieved mechanical properties:

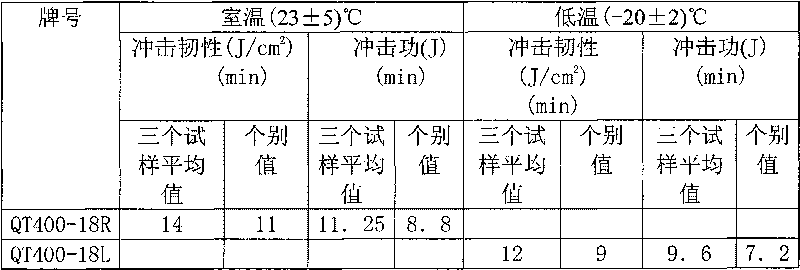

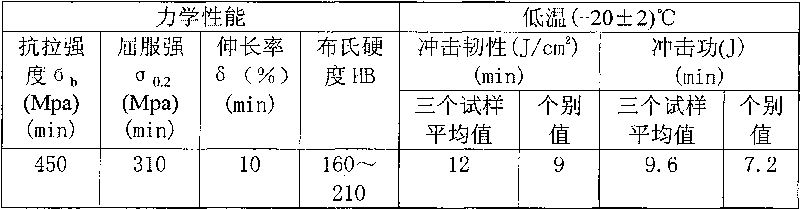

[0049] бb≥450Mpa, σ0.2≥310Mpa, δ≥10%, Akv value at -20°C±2°C: average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com