Clean energizing device for metal melt in steel ladle

A technology of molten metal and ladle, applied in the field of casting auxiliary devices, can solve the problems affecting the quality of castings, difficult to discharge air bubbles, difficult to float impurities, etc., to achieve the effect of improving the level of spheroidization, reducing the pouring temperature and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

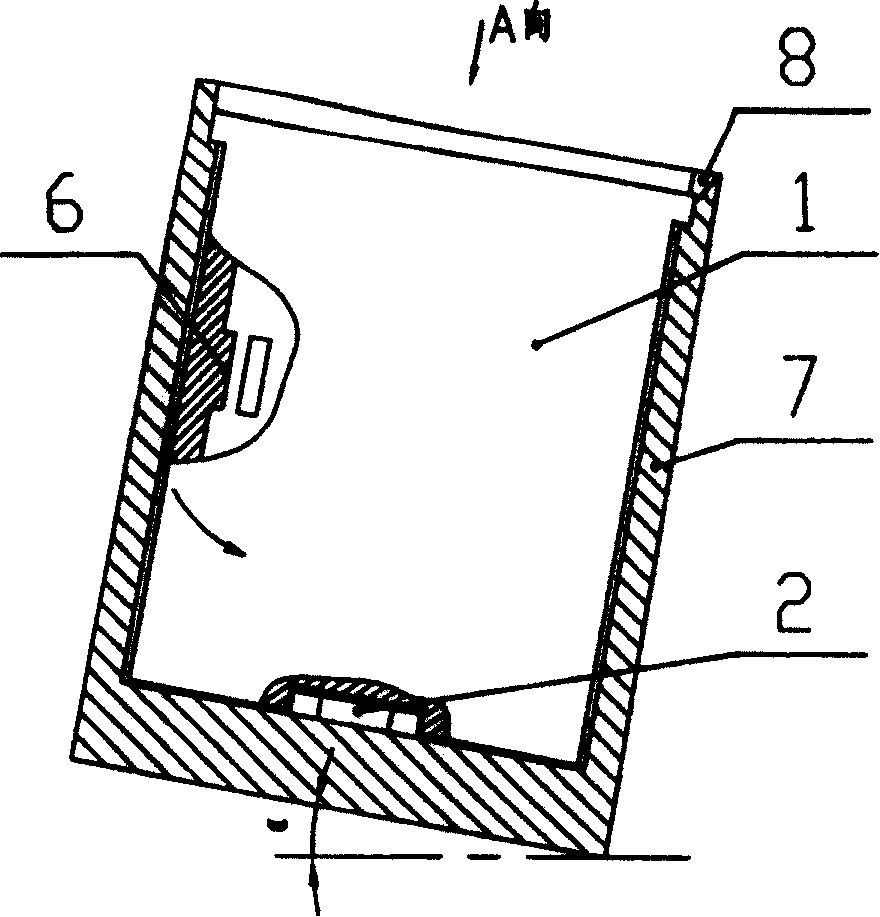

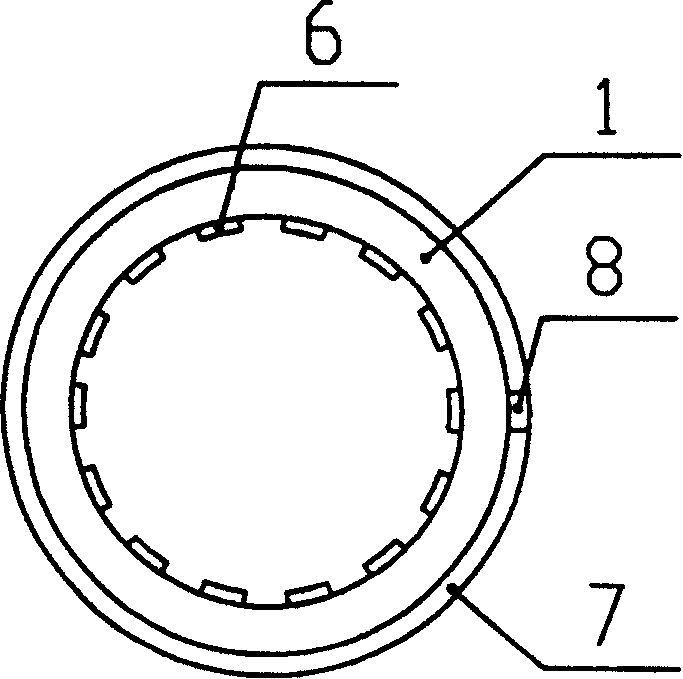

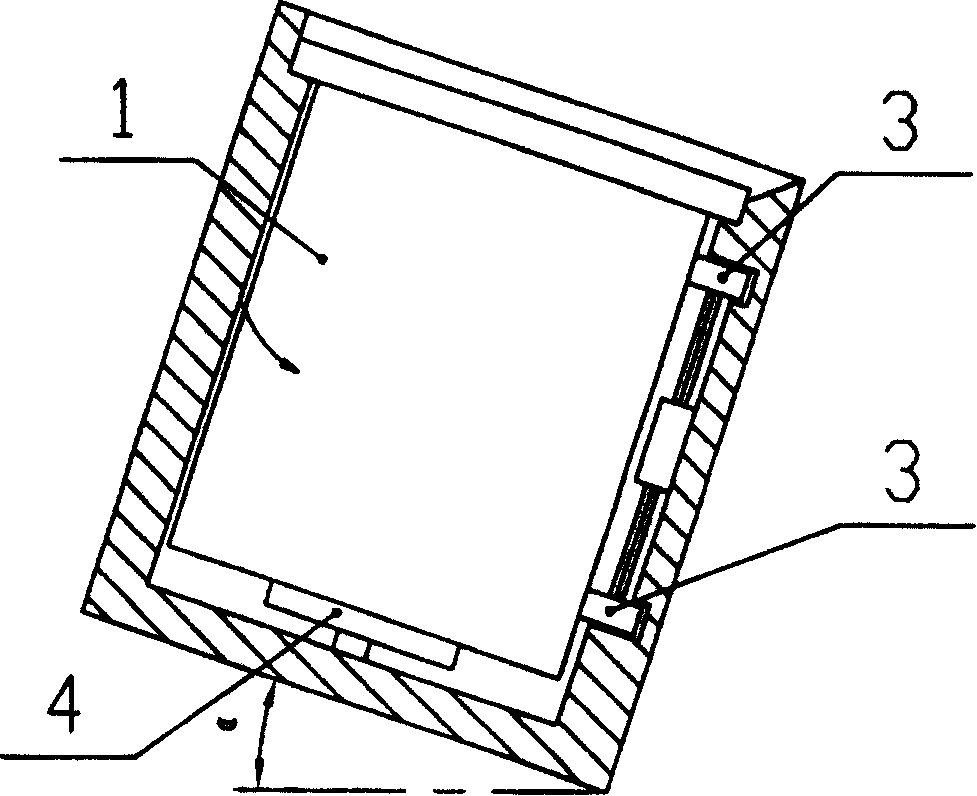

[0017] Such as Figure 1 to Figure 4 In the ladle molten metal pure energizing device shown, the ladle 1 is placed above the molten metal pure energizing device, and the molten metal pure energizing device includes a transmission structure that drives the ladle to rotate or vibrate. In order to enhance the movement effect of molten metal in the ladle, generally the ladle 1 is placed at a certain angle, and the inclination angle α is 5° to 70°. In addition, a protrusion 6 is provided on the inner wall of the ladle, and the protrusion 6 can be formed from the ladle. The continuous strip protrusions from the mouth to the bottom or discontinuous multiple strip protrusions, or spherical-shaped protrusions and other convex structural forms, similarly make the molten metal change direction in the ladle 1 The structure of the movement belongs to the structure protected by the utility model, so that during the rotation or vibration of the ladle 1, the molten metal and the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com