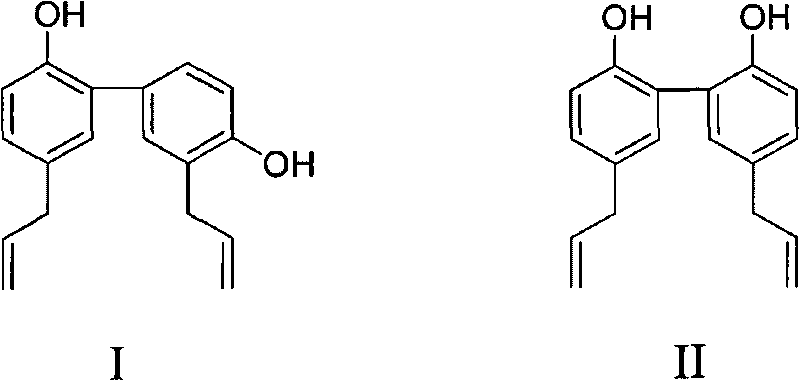

Method for extracting magnolol and honokiol from magnolia officinalis

A technology of honokiol and magnolol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the difficulty of separating magnolol and honokiol, the large amount of organic solvent used, and the extraction time Long and other problems, to achieve the effect of shortening the production cycle, less corrosive equipment, and short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take Magnolia officinalis powder 10g, add sodium carbonate and borax (mass ratio 2:1) altogether 0.1g, grind to powder particle size D 90 25 μm (detected by a particle size analyzer, the same below), add 50ml of water, stir at 5°C for 20 minutes, centrifuge to obtain precipitate A and supernatant A, add 6mol / L hydrochloric acid to the supernatant A to adjust the pH value to 1.0, static Place and centrifuge, get the precipitate to be the magnolol extract, the yield of magnolol is 0.40%, and the content of magnolol is 46.3%; take the precipitate A, add 2.0g sodium hydroxide, 250ml water, at 5 ℃ Stir for 60 minutes, centrifuge, take the supernatant and add 6mol / L hydrochloric acid to adjust the pH value to 2.0, centrifuge after standing, take the precipitate and get the honokiol extract, the yield of honokiol is 0.44%, and the honokiol The phenol content was 49.5%.

Embodiment 2

[0037] Take Magnolia officinalis powder 10g, add potassium carbonate 0.5g, grind to powder particle size D 90 95μm, add 100ml of water, stir at 20°C for 10min, centrifuge to obtain precipitate A and supernatant A, add glacial acetic acid to adjust the pH value of supernatant A to 5.0, let it stand and centrifuge, and take the precipitate as magnolol Extract, the yield is 1.20%, the content is 60.1%; take the precipitate A, add 1.0g calcium hydroxide, 150ml water, stir at 40°C for 15min, centrifuge, take the supernatant, add 6mol / L hydrochloric acid to adjust the pH value to 3.0, leave it to stand and then centrifuge to get the precipitate to be the honokiol extract, with a yield of 0.53% and a content of 62.1%.

Embodiment 3

[0039] Take 10g of magnolia powder, add 1.0g of borax, mix and grind to powder particle size D 90 57μm, add 100ml of water, stir at 40°C for 20min, centrifuge to obtain precipitate A and supernatant A, add 6mol / L hydrochloric acid to the supernatant A to adjust the pH value to 2.0, let stand and then centrifuge, take the precipitate and get the thickness Parkol extract, the yield is 1.30%, the content is 25.3%; take the precipitate A, add 0.5g calcium oxide, 100ml water, stir at 20°C for 30min, centrifuge, take the supernatant, add 6mol / L hydrochloric acid to adjust the pH When the value reaches 5.0, it is centrifuged after standing, and the precipitate is Honokiol extract, the yield is 0.57%, and the content is 63.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com