Calcium phosphate nano-structure hollow microsphere and preparation method thereof

A hollow microsphere and nanostructure technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high cost, complex process, difficult mass production, etc., and achieve low cost, simple process, and clean energy consumption. pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

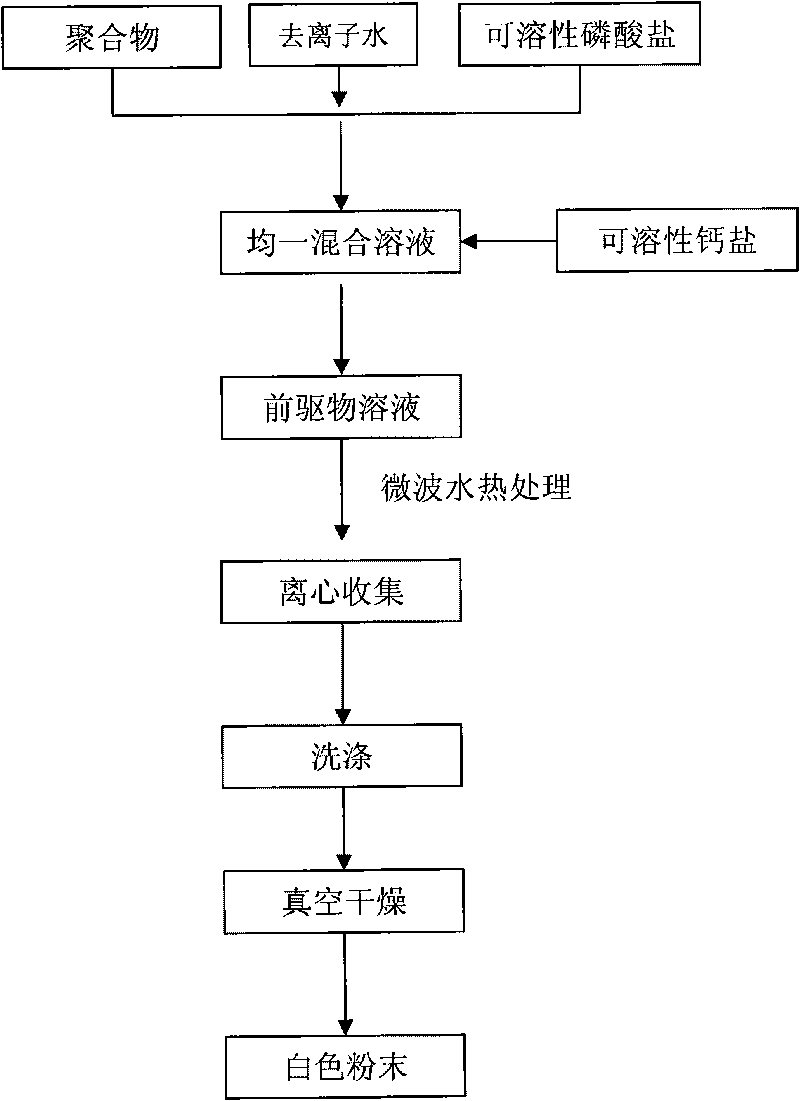

Method used

Image

Examples

Embodiment 1

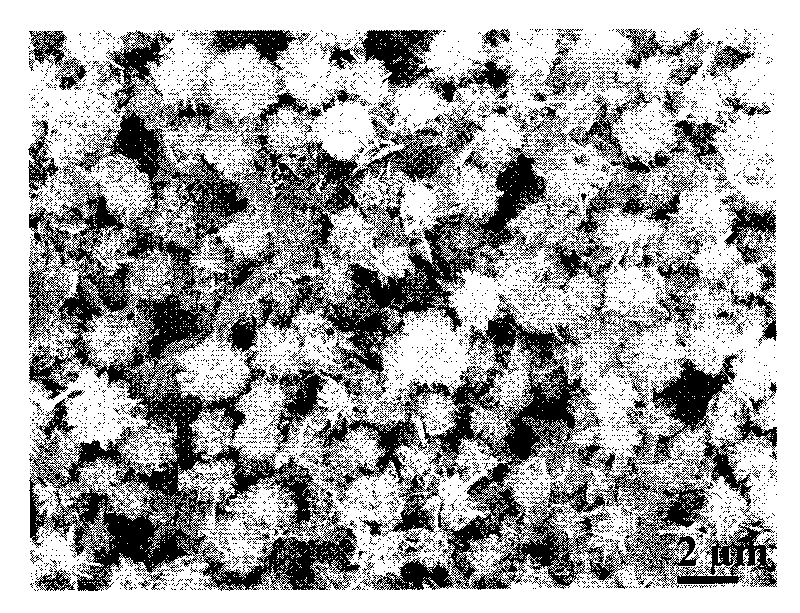

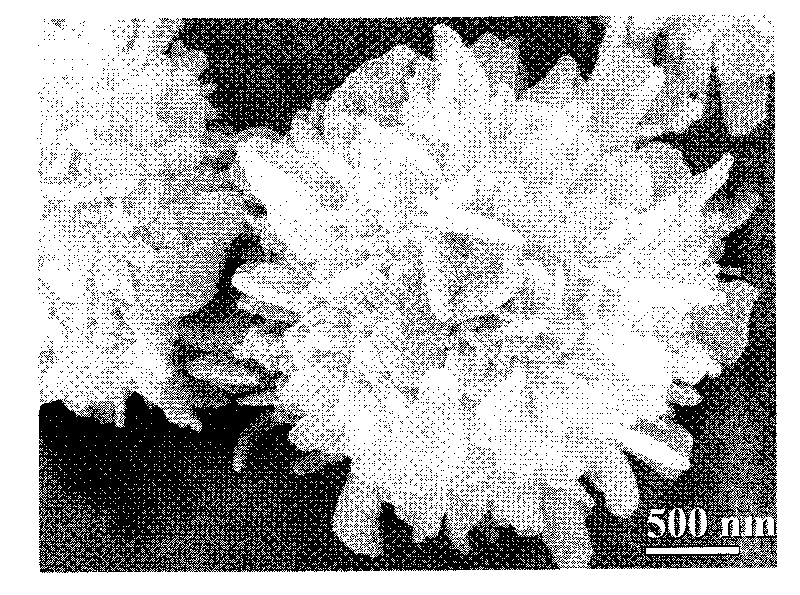

[0033] 0.07g PEG-PLA (PEG molecular weight 5000, EO / L A=4), 10mL containing 0.04M NaH 2 PO 4 and 0.04M Na 2 HPO 4 Solution and 20mL deionized water were mixed at room temperature, stirred for 60min, the pH value was adjusted to 5 with 0.5M dilute hydrochloric acid, and then 10mL 0.08M Ca(CH 3 COO) 2 , to form a clear precursor solution, and then transfer this solution to a 70mL reaction kettle, microwave heating to 120°C, and hydrothermal reaction for 5min. After cooling, the reaction solution was centrifuged, washed three times with deionized water and once with absolute ethanol, and then dried in vacuum at 37°C for 24 hours. The analysis shows that the obtained product is a calcium phosphate nanostructure hollow microsphere with a particle size of 1-2 μm.

Embodiment 2

[0035] 0.14g PEG-PLA (PEG molecular weight 5000, EO / LA=4), 10mL containing 0.04MNaH 2 PO 4 and 0.04M Na 2 HPO 4 Solution and 20mL deionized water were mixed at room temperature, stirred for 60min, the pH value was adjusted to 5 with 0.5M dilute hydrochloric acid, and then 10mL 0.08M Ca(CH 3 COO) 2 , to form a clear precursor solution, and then transfer this solution to a 70mL reactor, microwave heating to 120°C, and hydrothermal reaction for 60min. After cooling, the reaction solution was centrifuged, washed three times with deionized water and once with absolute ethanol, and then dried in vacuum at 37°C for 24 hours. The analysis shows that the obtained product is a calcium phosphate nanostructure hollow microsphere with a particle size of 1-2 μm.

Embodiment 3

[0037]0.07g PEG-PLA (PEG molecular weight 5000, EO / LA=4), 10mL containing 0.04MNaH 2 PO4 and 0.04M Na 2 HPO 4 Solution and 20mL deionized water were mixed at room temperature, stirred for 60min, the pH value was adjusted to 5 with 0.5M dilute hydrochloric acid, and then 10mL 0.08M Ca(CH 3 COO) 2 , to form a clear precursor solution, and then transfer this solution to a 70mL reactor, microwave heating to 120°C, and hydrothermal reaction for 30min. After cooling, the reaction solution was centrifuged, washed three times with deionized water and once with absolute ethanol, and then dried in vacuum at 37°C for 24 hours. The analysis shows that the obtained product is a calcium phosphate nanostructure hollow microsphere with a particle size of 1-2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com