Atomic layer deposition Al2O3/HfO2 method for regulating energy band offset between GaAs semiconductor and gate dielectric

An atomic layer deposition and gate dielectric technology, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve the problems of small conduction band compensation, inability to effectively suppress gate leakage current, and low barrier height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

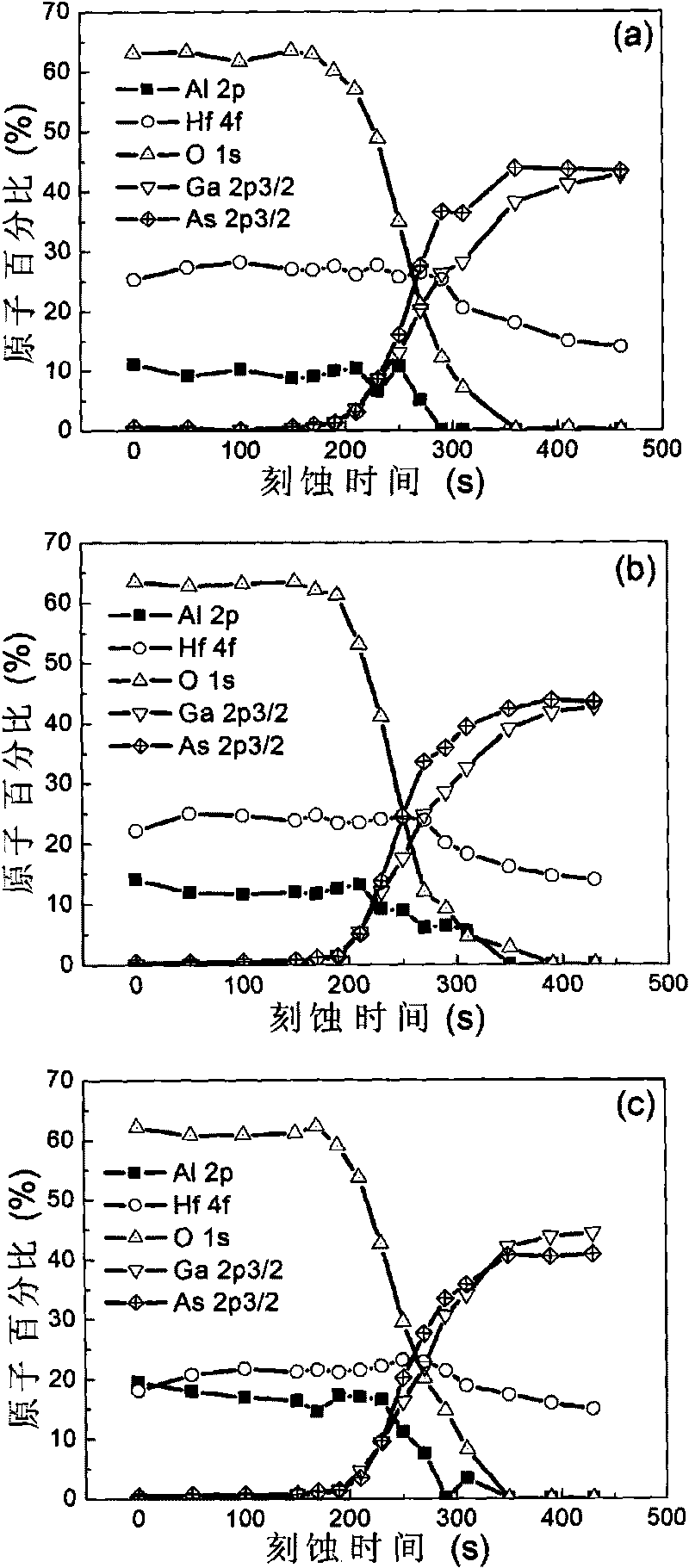

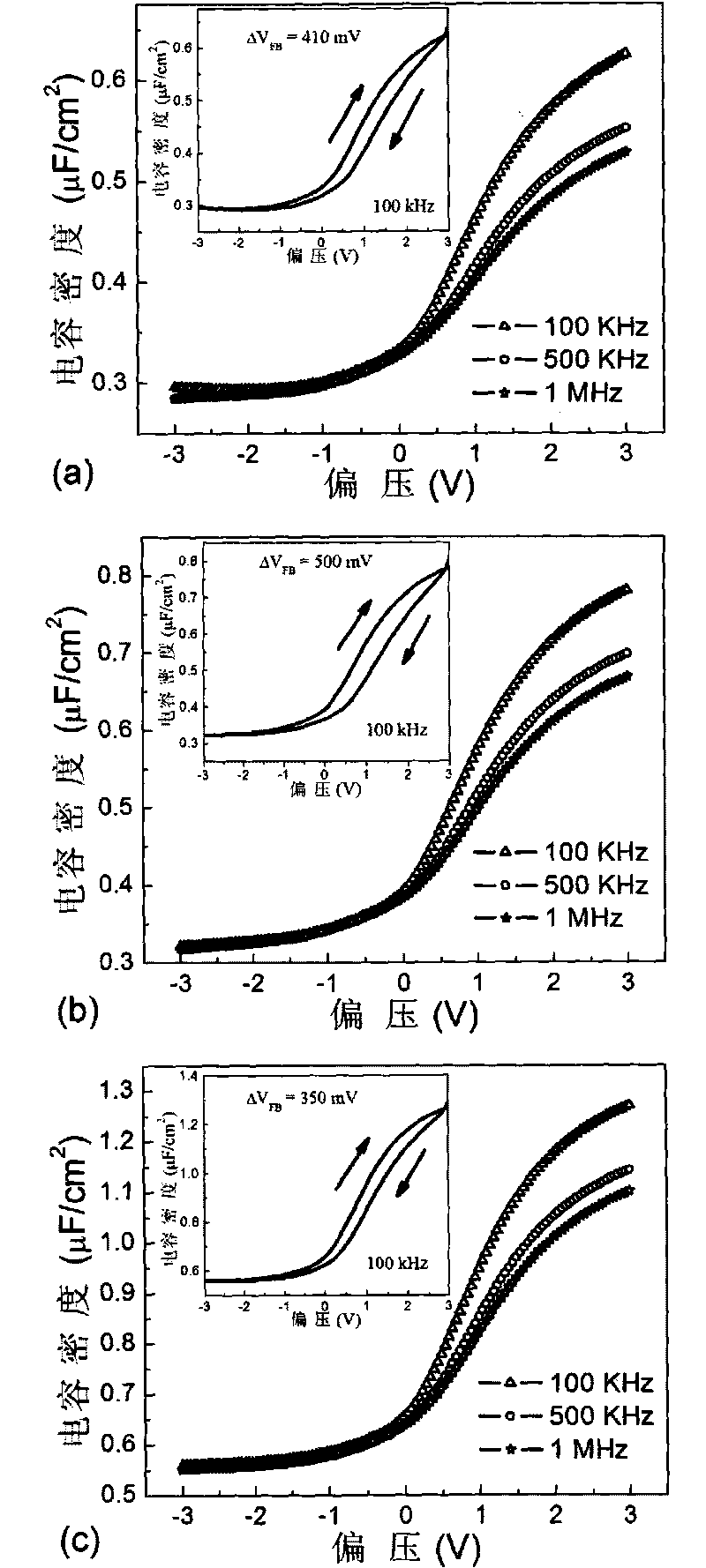

[0029] 1) Substrate cleaning: The GaAs substrate was ultrasonically cleaned with acetone, ethanol, and isopropanol for 3 minutes to remove the oil on the GaAs surface, and then soaked in HCl aqueous solution for 3 minutes. The volume ratio of the HCl aqueous solution is HCl:H 2 O=1:10.

[0030] 2) Substrate passivation: clean the GaAs substrate with 8% volume ratio (NH 4 ) 2 Soak in S aqueous solution for 10 minutes to form Ga-S and As-S bonds on the surface of GaAs, and further remove excess As simple substance and As oxide;

[0031] 3) Set the ALD deposition parameters: put the passivated GaAs substrate into the ALD reaction chamber immediately, and perform HfO 2 / Al 2 o 3 For the deposition of nano-laminated thin films, the ALD deposition parameters set are:

[0032] Reaction chamber temperature: 250°C;

[0033] Reaction source: deposited Al 2 o 3 Using Al(CH 3 ) 3 and H 2 O reaction; deposition of HfO 2 Using HfCl 4 and H 2 O reaction, where HfCl 4 The sourc...

Embodiment 2

[0037] 1) Substrate cleaning: ultrasonically clean the GaAs substrate with acetone, ethanol, and isopropanol for 10 minutes in order to remove the oil on the GaAs surface, and then soak it in HCl aqueous solution for 5 minutes. The volume ratio of the HCl aqueous solution is HCl:H 2 O=1:10.

[0038] 2) Substrate passivation: clean the GaAs substrate with 40% volume ratio (NH 4 ) 2 Soak in S aqueous solution for 40 minutes to form Ga-S and As-S bonds on the surface of GaAs, and further remove excess As simple substance and As oxide;

[0039] 3) Set the ALD deposition parameters: put the passivated GaAs substrate into the ALD reaction chamber immediately, and perform HfO 2 / Al 2 o 3 For the deposition of nano-laminated thin films, the ALD deposition parameters set are:

[0040] Reaction chamber temperature: 350°C;

[0041] Reaction source: deposited Al 2 o 3 Using Al(CH 3 ) 3 and H 2 O reaction; deposition of HfO 2 Using HfCl 4 and H 2 O reaction, where HfCl 4 The...

Embodiment 3

[0045] 1) Substrate cleaning: ultrasonically clean the GaAs substrate with acetone, ethanol, and isopropanol for 5 minutes in order to remove the oil on the GaAs surface, and then soak it in HCl aqueous solution for 4 minutes. The volume ratio of the HCl aqueous solution is HCl:H 2 O=1:10.

[0046] 2) Substrate passivation: clean the GaAs substrate with 25% volume ratio (NH 4 ) 2 Soak in S aqueous solution for 30 minutes to form Ga-S and As-S bonds on the surface of GaAs, and further remove excess As element and As oxide;

[0047] 3) Set the ALD deposition parameters: put the passivated GaAs substrate into the ALD reaction chamber immediately, and perform HfO 2 / Al 2 o 3 For the deposition of nano-laminated thin films, the ALD deposition parameters set are:

[0048] Reaction chamber temperature: 300°C;

[0049] Reaction source: deposited Al 2 o 3 Using Al(CH 3 ) 3 and H 2 O reaction; deposition of HfO 2 Using HfCl 4 and H 2 O reaction, where HfCl 4 The source te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com