Low temperature heat-treatment process for eliminating water mist on silicon chip surface

A technology for low-temperature heat treatment and silicon wafer surface, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of increasing the surface micro-roughness of silicon wafers and increasing surface particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

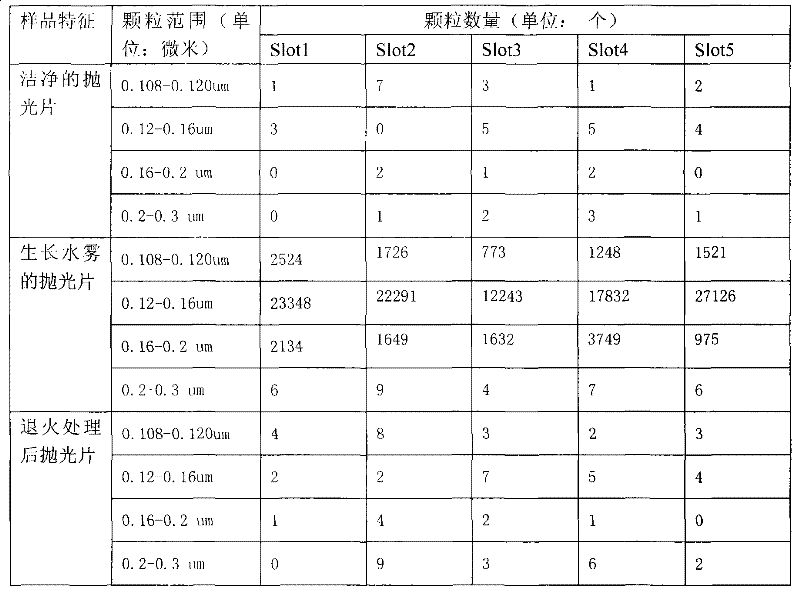

[0023] Take 5 pieces of clean silicon wafers, grow "water mist" in a simulated high-humidity environment, and then do low-temperature heat treatment. A laser particle counter was used to scan the distribution of surface particles before growth, after growth, and after low-temperature heat treatment.

[0024] The simulated high-humidity environment is realized by placing silicon wafers in slots 1-5 of the cassette. At the same time, the silicon wafer side of the cassette is raised. Then drop 5ml of ultra-high-purity deionized water into the bottom of the 25th slot of the cassette, and then seal it for storage. During the sealing process, ensure that 5ml of water will not reach the surface of the silicon wafer. After 2 days of storage, open the cassette to measure the particles on the surface of the silicon wafer, and then perform low-temperature heat treatment in a single-chip furnace. The low temperature heat treatment temperature is 300° C., the constant temperature time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com