Method for measuring rare earth component in rare earth magnesium alloy

A rare earth magnesium and alloy technology, applied in the field of iron and steel metallurgy analysis, can solve the problem of no standard for measuring the rare earth content of rare earth magnesium alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

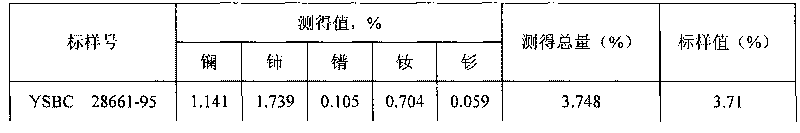

Examples

Embodiment Construction

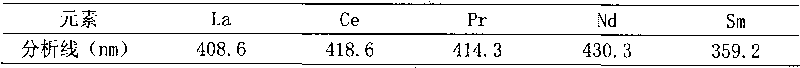

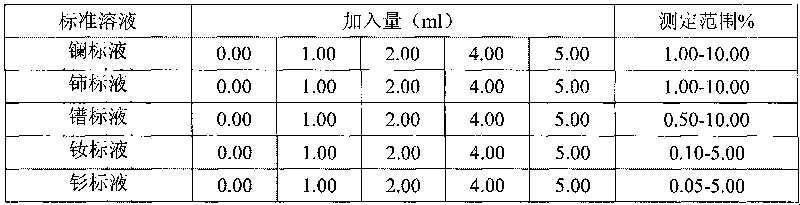

[0013] 1. Method summary

[0014] Dissolve the sample with nitric acid and hydrofluoric acid, fume with perchloric acid, dilute to a certain volume, introduce the atomized solution into the inductive plasma atomic emission spectrometer, measure the spectral line intensity of the element to be measured, and measure it according to the known concentration of the standard substance The intensity of the spectral line is calculated to obtain the concentration of the corresponding element of the substance to be measured.

[0015] 1. Main instruments

[0016] 1.1 IRIS Intrepid II high-resolution, high-sensitivity full-spectrum direct-reading inductively coupled plasma emission spectrometer from American Thermo Company; TEVA software (version: 1.5.0).

[0017] 1.2 Instrument measurement conditions:

[0018] The high-frequency generator power is 1150W, the auxiliary gas flow rate is 0.5L / min, the nebulizer pressure is 30psi, the peristaltic pump speed is 130rpm, the number of repetit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com