Preparation method of Cu/Ta nanometer multilayer film with crystal particle dimension difference

A grain size, nano-multilayer technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of low ductility and undiscovered problems, achieve low cost, improve mechanical properties, and highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

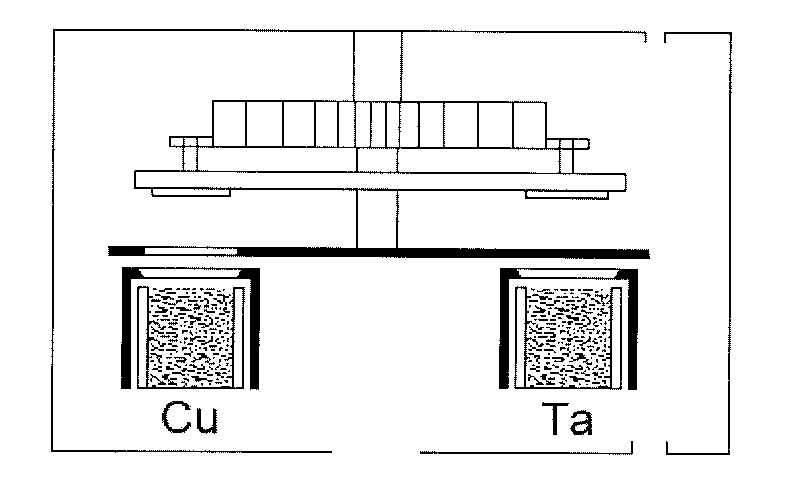

[0025] The preparation process of the Cu / Ta nanometer multilayer film, wherein the DC magnetron sputtering current of the Cu target during double target sputtering is 0.1-0.15A, and the voltage is 200V; the Ta DC magnetron sputtering current is 0.15-0.2 A, the voltage is 250V; the negative bias is 100V, and the distance between the substrate and the target is 5-8cm.

[0026] The ambient temperature of the substrate during deposition is room temperature, about 290-300K.

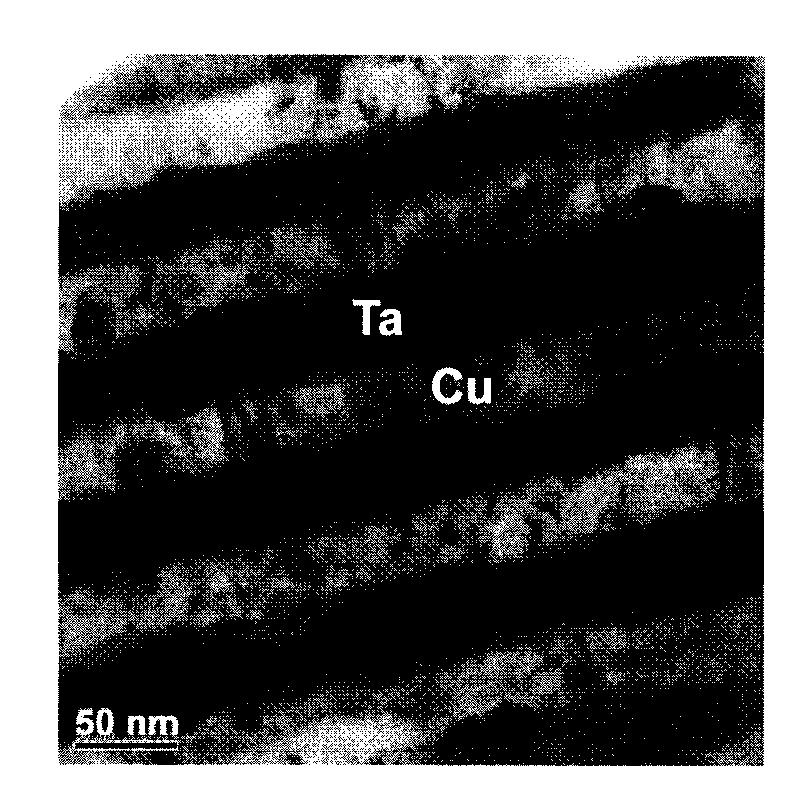

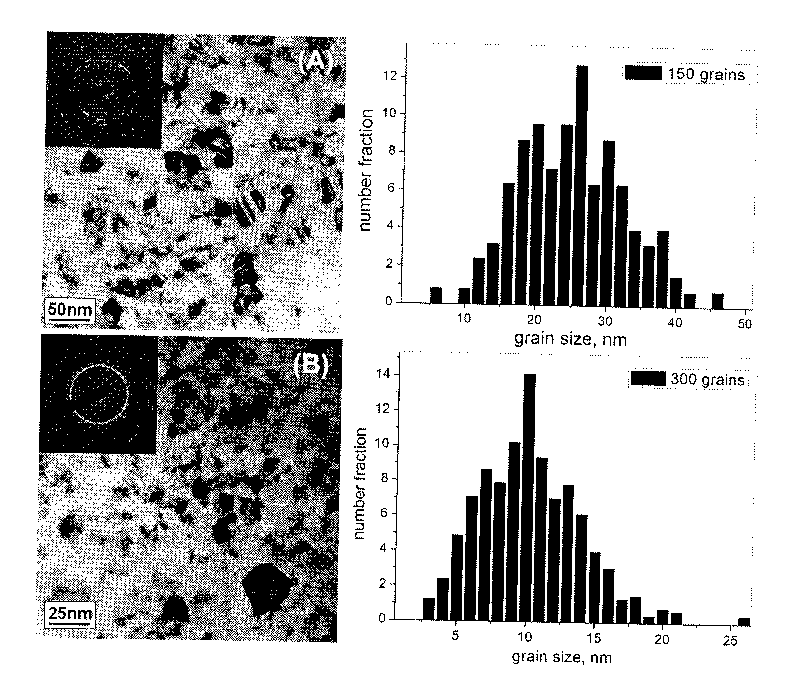

[0027] The present invention adds an important technical step in the process of synthesizing the multilayer film: adopting different sputtering powers to the Cu target and the Ta target, so that the metal nano multilayer film obtains different grain sizes, see figure 2 . The alternating structure of coarse-grained material and fine-grained material improves the strength and plastic deformation ability of the metal nano-multilayer film.

example 1

[0029] The specific technological parameter of the manufacture method of Cu / Ta nanometer multilayer film of the present invention is: adjust the Cu target DC magnetron sputtering current to be 0.15A, the Cu target DC magnetron sputtering power is 30W, and the deposition time is 83 seconds; The Ta target DC magnetron sputtering current is 0.2A, the Ta target DC magnetron sputtering power is 50W, and the deposition time is 143 seconds. The substrate temperature is room temperature. The thus obtained Cu / Ta nanometer multilayer film has a modulation wavelength of 70 nanometers. Wherein the Cu layer is 35 nanometers, and the Ta layer is also 35 nanometers.

example 2

[0031] The concrete process parameter of the manufacture method of Cu / Ta nanometer multilayer film of the present invention is: adjust the Cu target DC magnetron sputtering current to be 0.15A, the Cu target DC magnetron sputtering power is 30W, and the deposition time is 60 seconds; The Ta target DC magnetron sputtering current is 0.2A, the Ta target DC magnetron sputtering power is 50W, and the deposition time is 102 seconds. The substrate temperature is room temperature. The thus obtained Cu / Ta nanometer multilayer film has a modulation wavelength of 50 nanometers. Wherein the Cu layer is 25 nanometers, and the Ta layer is also 25 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com