Sintered product of rejects and shale modular cellular bricks and preparing method thereof

A technology for sintered products and porous bricks, which is applied in the field of sintered products of shale modulus porous bricks from mining waste slag and its preparation. Improve the aesthetic effect of appearance texture, significant social and economic benefits, and improve the effect of plasticity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The sintered product of the mining and dressing waste shale modulus porous brick of the present invention is prepared by the following steps:

[0019] (1) Crushing: The mining and dressing waste in Zhongshan Coal Mine—coal gangue and shale are mixed in proportion and synchronously go through coarse crushing, fine crushing and sieving to make the raw material fineness reach less than 1.5mm, and 0.5mm accounts for 68 %, 0.25mm accounts for 36%;

[0020] (2) Ingredients: mix gangue and shale in a weight ratio of 85:15, add water and stir evenly, increase the added water from the usual 17% to 20%, and send it to storage and storage for less than 3 days Half;

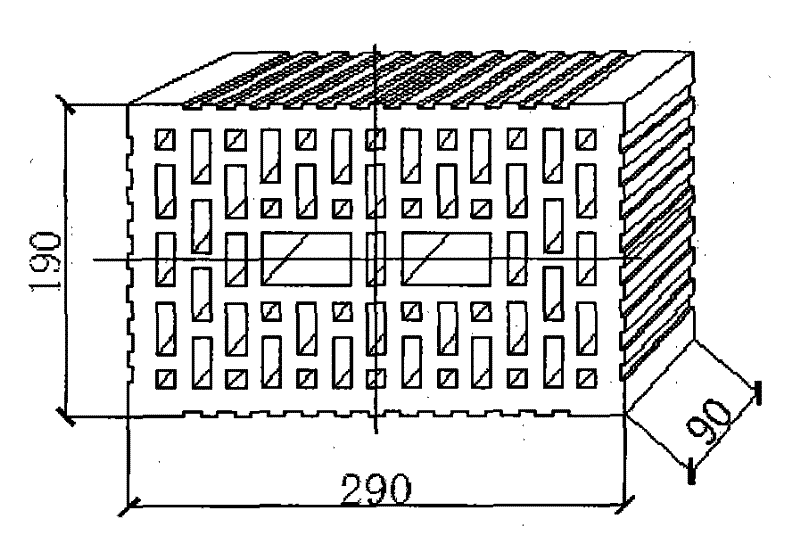

[0021] (3) Molding: Send the stored material into the molding machine for semi-rigid plastic extrusion molding. Such as figure 1 As shown, the molded product is 11 rows of dislocated rectangular hole main bricks through the design of the main machine outlet mold, the specification size is 190×240×90 (mm), the vacuu...

Embodiment 2

[0032] The sintered product of the mining and dressing waste shale modulus porous brick of the present invention is prepared by the following steps:

[0033] (1) Crushing: Copper tailings and shale, which are mining and dressing waste residues in the Guli Copper Mine, are properly proportioned and synchronously undergo coarse crushing, fine crushing and sieving to make the raw material fineness reach a particle size of less than 1.5mm, 0.5mm Accounted for 65%, 0.25mm accounted for 35%;

[0034] (2) Batching: Batching copper tailings and shale at a weight ratio of 80:20, adding water and stirring evenly, increasing the amount of water added from the usual 16% to 18%, and sending it into storage and storage for 3 hours sky;

[0035] (3) Molding: Send the stored material into the molding machine for semi-rigid plastic extrusion molding. Such as Figure 4 , as shown in Figure 5, after the design of the main machine outlet mold, the formed product is 11 rows of dislocated rectan...

Embodiment 3

[0046] The sintered product of the mining and dressing waste shale modulus porous brick of the present invention is prepared by the following steps:

[0047](1) Crushing: Mix the waste residue of medium mining and beneficiation in Huzhou, Zhejiang Province - sand tailings and shale in proportion, and synchronously go through coarse crushing, fine crushing and sieving to make the raw material fineness reach less than 1.5mm, 0.5mm accounted for 69%, 0.25mm accounted for 37%;

[0048] (2) Ingredients: mix sand tailings and shale at a weight ratio of 75:25, add water and stir evenly, increase the amount of water added from the usual 16% to 20%, and send it to storage and storage, and the time is not 3 sky;

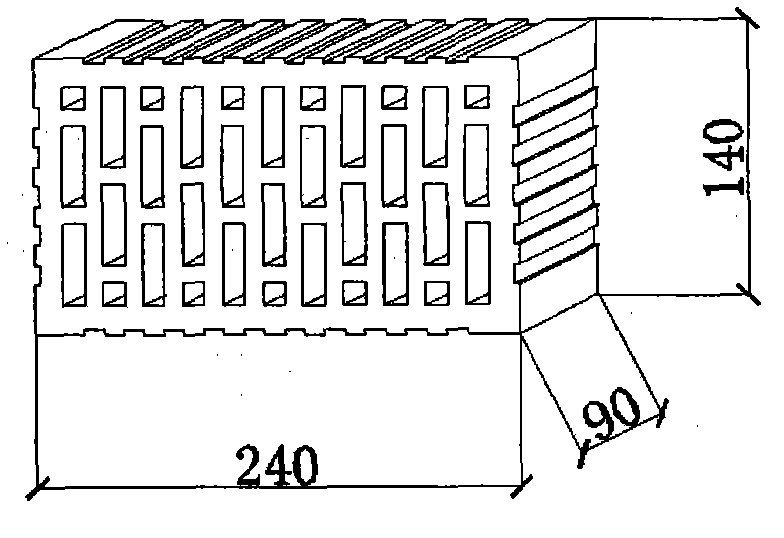

[0049] (3) Molding: Send the stored material into the molding machine for semi-rigid plastic extrusion molding; through the design of the main machine outlet mold, the molded product is 11 rows of misplaced rectangular strip holes with bricks, and the size is 140×240 ×90(mm)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com