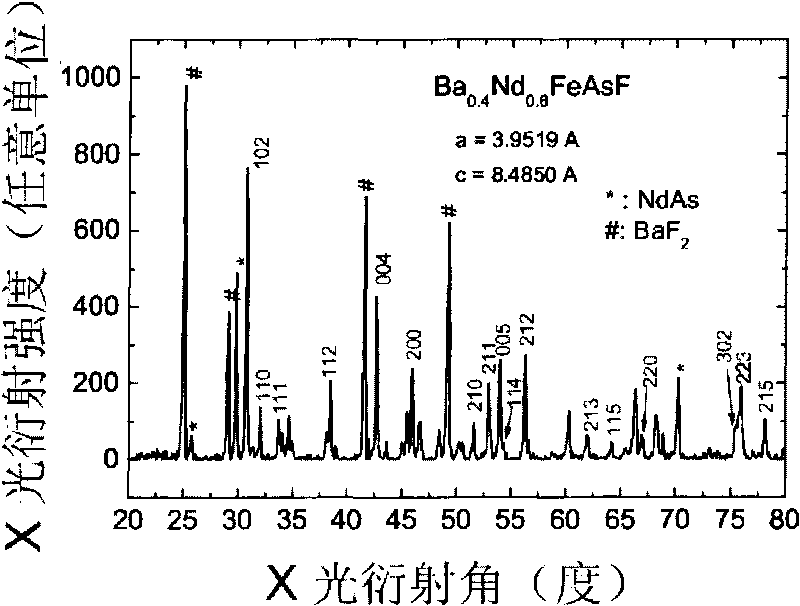

Single-phase iron-based superconducting material based on fluoride and preparation method thereof

A technology of superconducting materials and fluorides, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., to achieve the effects of ensuring high quality, reducing intermediate links, and saving energy and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

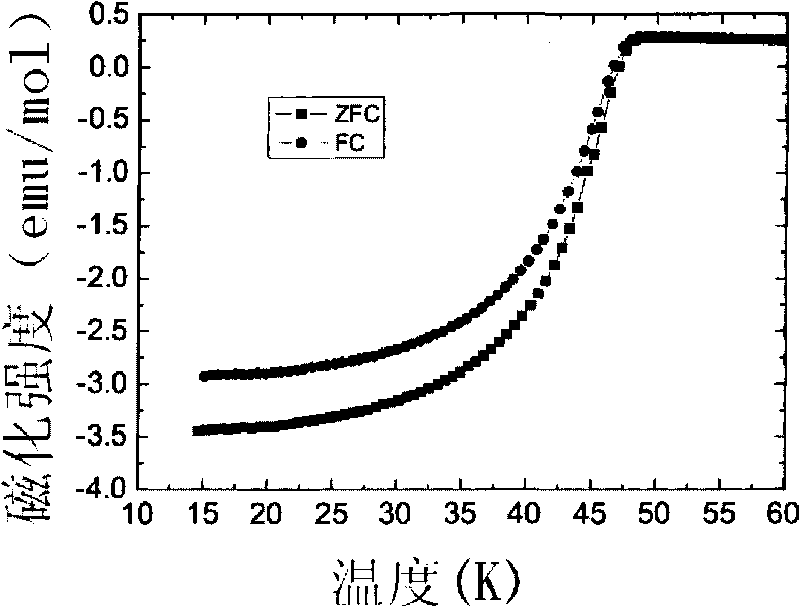

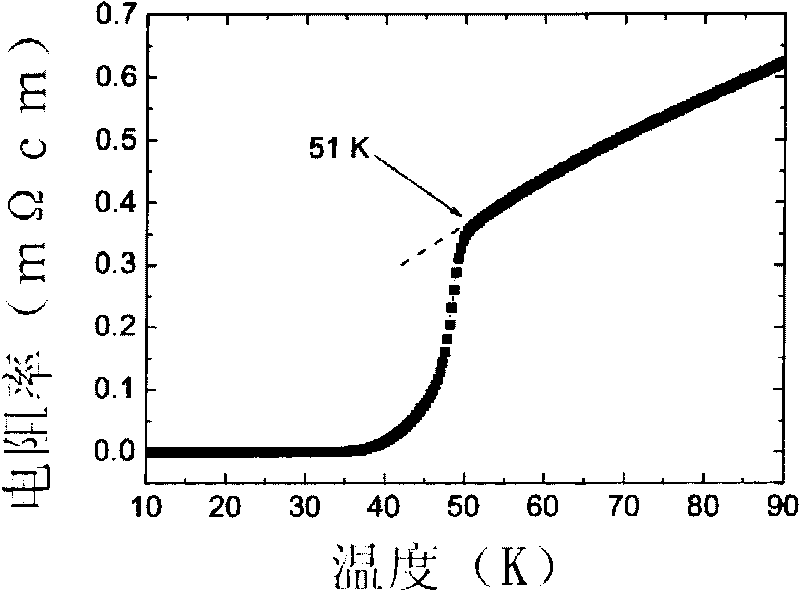

Examples

Embodiment 1

[0034] Synthesis of superconducting materials by solid-state reaction method (Ba 1-x RE x ) FeAsF, where x=0.50, RE=La. The operation steps are as follows

[0035] 1) Step 1: Preparation of the precursor: using a solid state reaction method, mix and grind As particles with a purity of 99.5% and Ba particles with a purity of 99%-99.99% at a molar ratio of 1:1, and then press them into a small circle with a diameter of 10mm Tablets, wherein the tablet pressure is 2Mpa; sealed in a high vacuum (about 10 -5 Pa) in a quartz tube or a high-melting-point metal tube, first slowly raise the temperature to 500°C for 12 hours, and then sinter at 680°C for 10 hours to obtain the BaAs compound;

[0036] Use the same method to prepare the LaAs precursor, except that the second step needs to be sintered at 720°C for 10 hours to obtain the LaAs precursor;

[0037] The BaAs and LaAs precursor samples can also be ground, returned to the furnace, and re-sintered, and the process of step 1) c...

Embodiment 2

[0042] Synthesis of superconducting materials by solid-state reaction method (Ba 1-x RE x ) FeAsF, where x=0.45, RE=Ce. The operation steps are as follows

[0043] 1) Step 1: Preparation of the precursor: using a solid state reaction method, mix and grind As particles with a purity of 99.5% and Ba particles with a purity of 99%-99.99% at a molar ratio of 1:1, and then press them into a small circle with a diameter of 10mm Tablets (wherein the tableting pressure is 3Mpa), sealed in a high vacuum (about 10 -5 Pa) in a quartz tube or a high-melting-point metal tube, first slowly raise the temperature to 500°C for 12 hours, and then sinter at 680°C for 10 hours to obtain the BaAs compound; the preparation of the CeAs precursor is basically similar to that of BaAs, except that The second step requires sintering at 780°C for 10 hours; BaAs and CeAs precursor samples are ground, returned to the furnace, and re-sintered to ensure sample uniformity;

[0044] 2) Step 2: Synthesis: T...

Embodiment 3

[0048] Synthesis of superconducting materials by solid-state reaction method (Ba 1-x RE x ) FeAsF, where x = 0.35, RE = Pr. The operation steps are as follows

[0049] 1) Step 1: Preparation of the precursor: using a solid state reaction method, mix and grind As particles with a purity of 99.5% and Ba particles with a purity of 99%-99.99% at a molar ratio of 1:1, and then press them into a small circle with a diameter of 10mm Tablets (wherein the tableting pressure is 4Mpa), sealed in a high vacuum (about 10 -5 Pa) in a quartz tube or a high-melting-point metal tube, first slowly raise the temperature to 500°C for 12 hours, and then sinter at 680°C for 10 hours to obtain the BaAs compound; the preparation of the PrAs precursor is basically similar to that of BaAs, except that The second step requires sintering at 750°C for 10 hours; BaAs and PrAs precursor samples are ground, returned to the furnace, and re-sintered to ensure sample uniformity;

[0050] 2) Step 2: Synthesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com