Method and equipment for continuous preparation of metallic oxide material and catalyst

A metal material, oxide technology, applied in metal/metal oxide/metal hydroxide catalyst, oxide/hydroxide preparation, chemical instruments and methods, etc. Uniform dispersion, inability to obtain expected performance products, etc., to avoid precipitants and save industrial raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

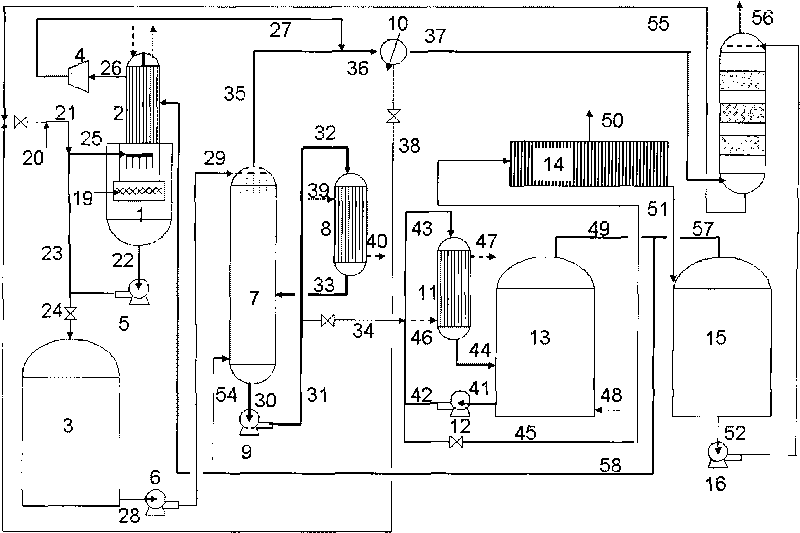

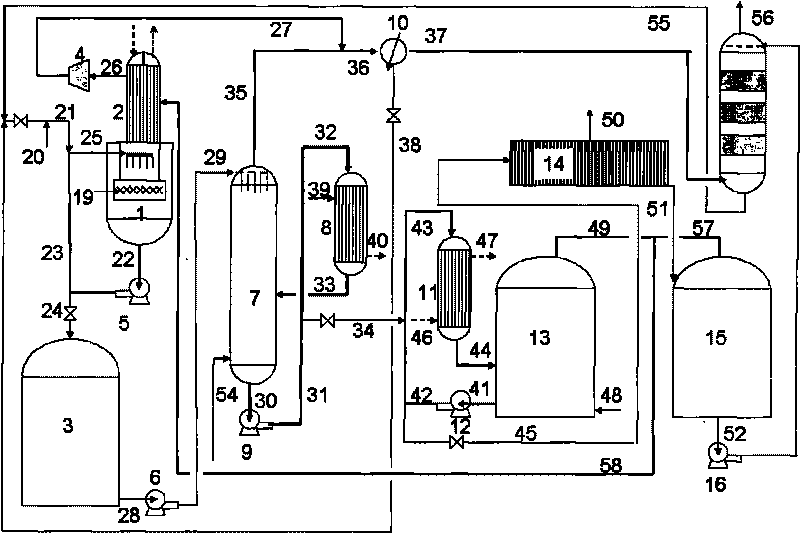

Method used

Image

Examples

Embodiment 1

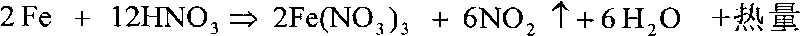

[0139] In metal salt solution preparation reactor, Fe powder and Mn powder are according to the ratio of Fe: Mn=100: 18 (wt), are dissolved with the nitric acid of 35wt% from absorption tower, make the metal nitric acid that concentration is 25.5wt% Salt solution, adding an appropriate amount of aluminum sol;

[0140] Then, carry out thermal decomposition reaction with pressurized superheated steam (the temperature of described pressurized superheated steam is 140 ℃; pressure is 4.6bar) in metal salt solution decomposition reactor, reaction temperature 120 ℃, pressure 6bar, Made into brown-black precipitated slurry;

[0141] COLLECTION OF NO GENERATED 2 The gas is recovered by the compression system, and passed into the acid gas absorption tower, and the filtrate produced by slurry filtration is used as the absorption liquid for spray absorption, and the nitric acid with a concentration of 35wt% is produced, which is recycled as the solvent raw material for the configuration ...

Embodiment 2

[0144] In the transition metal salt solution preparation reaction kettle, block Fe, Cu and Zn are dissolved with 48wt% nitric acid from the absorption tower according to the ratio of Fe: Cu: Zn = 100: 6: 8 (wt), to prepare Concentration is the metal nitrate solution of 37.7wt%;

[0145] Carry out thermal decomposition reaction with pressurized superheated steam (the temperature of described pressurized superheated steam is 230 ℃; pressure is 28bar) in metal salt solution decomposition reactor, reaction temperature 190 ℃, pressure 15bar, make brown Red precipitated slurry, the slurry is filtered to make a filter cake with a solid content rate of 27.3wt%;

[0146] collected NO 2 The gas is recovered through a compression system (at a pressure of 3 bar), and passed into an acid gas absorption tower to use the filtrate produced by slurry filtration as an absorption liquid for spray absorption to produce nitric acid with a concentration of 48 wt%, which is recycled as a metal salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com