Silica nanoscale hybridized sol thermochromatic finishing method for fabric

A technology of silica and thermochromism, which is applied in fiber treatment, textiles and papermaking, natural fibers, etc., can solve the problems of uneven dispersion of microcapsules, achieve good application prospects, overcome uneven dispersion, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

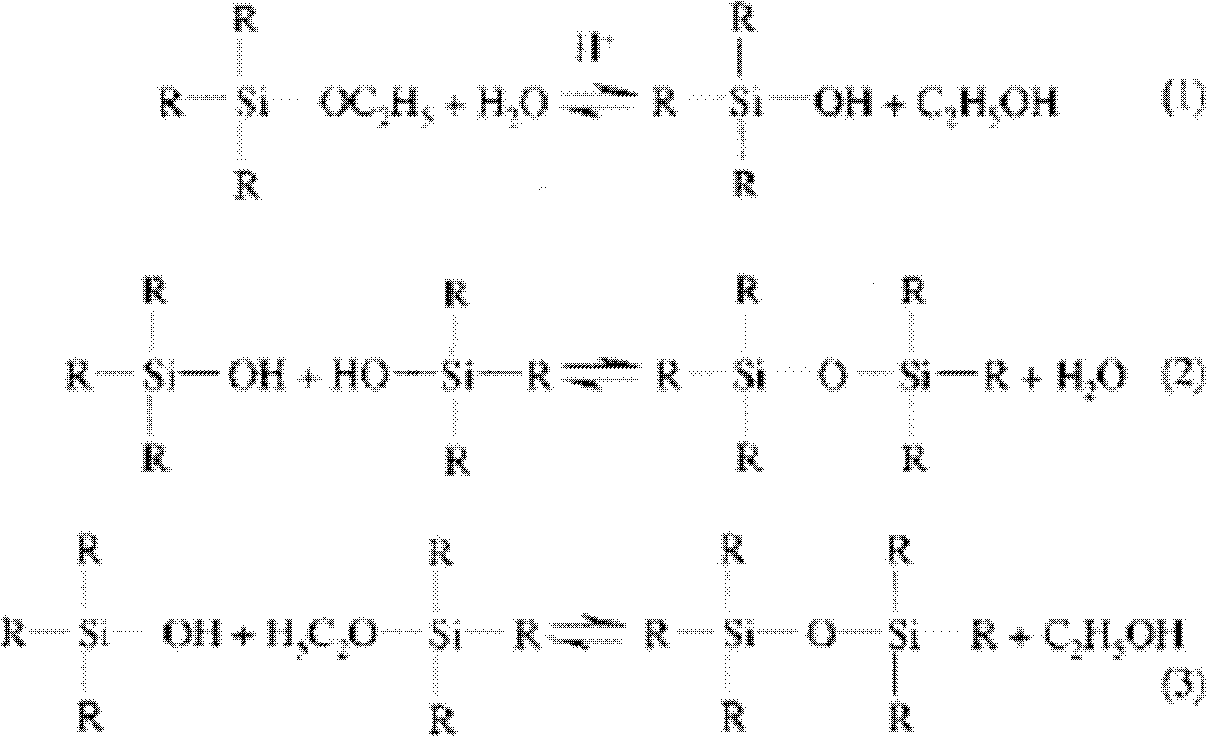

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of finishing solution

[0032] At room temperature, dissolve tetraethyl orthosilicate and silane coupling agent KH-560 in absolute ethanol, stir on a magnetic stirrer for 30 minutes to mix evenly, add 1 / 8 of the amount of deionized water under stirring , continue to stir for 15 minutes to form A solution; mix another 7 / 8 of the amount of deionized water and hydrochloric acid to form B solution; slowly add B solution to A solution under rapid stirring to adjust pH = 2, continue Stir for 2.5h to obtain transparent nano-SiO 2 sol, and then slowly add 30 g of triarylmethane phthalide thermochromic materials, and stir for 30 hours to obtain a hybrid nano-silica sol. The molar ratio of tetraethyl orthosilicate, silane coupling agent, ethanol and water is as follows: 1:1.5:24:40; the mass ratio of thermochromic material to silica sol is 1:10.

[0033] (2) Thermochromic finishing

[0034] Immerse cotton poplin 4040×3372 in the above-mentioned sol finishing so...

Embodiment 2

[0038] (1) Preparation of finishing solution

[0039]At room temperature, dissolve tetraethyl orthosilicate and silane coupling agent KH-560 in absolute ethanol, stir on a magnetic stirrer for 30 minutes to mix evenly, add 1 / 8 of the amount of deionized water under stirring , continue to stir for 15 minutes to form A solution; mix another 7 / 8 of the amount of deionized water and sulfuric acid to form B solution; slowly add B solution to A solution under rapid stirring to adjust pH = 3, continue Stir for 2.5h to obtain transparent nano-SiO 2 sol, and then slowly add 30 g of triarylmethane phthalide thermochromic materials, and stir for 30 hours to obtain a hybrid nano-silica sol. The molar ratio of tetraethyl orthosilicate, silane coupling agent, ethanol and water is as follows: 1:2:30:40; the mass ratio of thermochromic material to silica sol is 1:30.

[0040] (2) Thermochromic finishing

[0041] Immerse cotton poplin 4040×3372 in the above-mentioned sol finishing solution ...

Embodiment 3

[0045] (1) Preparation of finishing solution

[0046] At room temperature, dissolve tetraethyl orthosilicate and silane coupling agent KH-560 in absolute ethanol, stir on a magnetic stirrer for 30 minutes to mix evenly, add 1 / 8 of the amount of deionized water under stirring , continue to stir for 15 minutes to form A solution; mix another 7 / 8 of the amount of deionized water and acetic acid to form B solution; slowly add B solution to A solution under rapid stirring to adjust pH = 2, continue Stir for 2.5h to obtain transparent nano-SiO 2 sol, and then slowly add 30 g of triarylmethane phthalide thermochromic materials, and stir for 30 hours to obtain a hybrid nano-silica sol. The molar ratio of tetraethylorthosilicate, silane coupling agent, ethanol and water is as follows: 1:2:30:40; the mass ratio of thermochromic material to silica sol is 1:35.

[0047] (2) Thermochromic finishing

[0048] Immerse cotton poplin 4040×3372 in the above-mentioned sol finishing solution fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com