Noise reduction system for cement grinding production line

A noise reduction system and production line technology, applied in grain processing, etc., can solve problems such as electromagnetic noise of motors, and achieve the effects of ensuring stable operation, reducing pollution, and meeting heat dissipation needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

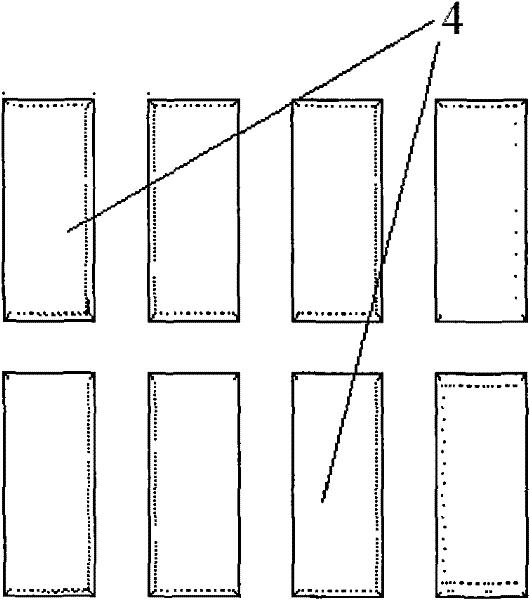

[0041] Such as image 3 As shown, the structure of the gate of the mill 1 of the present invention is a double-layer sealed and sound-insulated gate 9 of a flat-opening heavy body. Install the flat-opening heavy double-dense sound insulation door 9, and the sound insulation can reach STC35dB.

Embodiment 2

[0043] The window of natural lighting of mill 1 of the present invention adopts PVC double-layer fixed window.

Embodiment 3

[0045] Ventilation windows are provided on the walls of the mill 1 according to the present invention, and noise-eliminating elbows are provided on the ventilation windows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com