Method for defrosting based on by-pass circulating defrosting structure of refrigerator

A refrigerator and circulation type technology, which is applied to the defrosting field based on the bypass circulation type defrosting structure of the refrigerator, can solve the problems of condensation on the surface of the stored items, deterioration of the stored items, shortening the storage period of the items, etc. Short, prevent dissipation, temperature stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

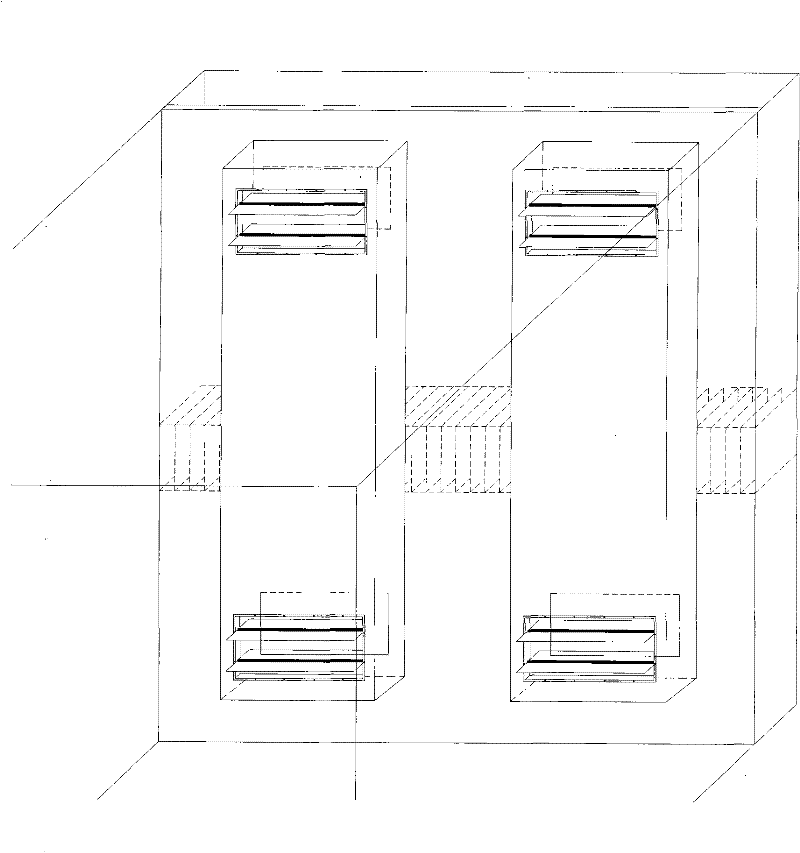

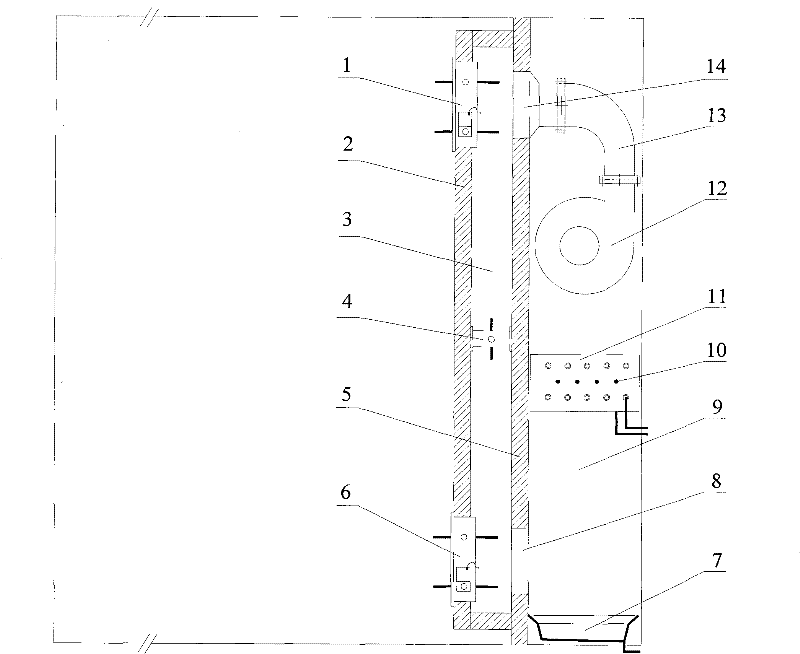

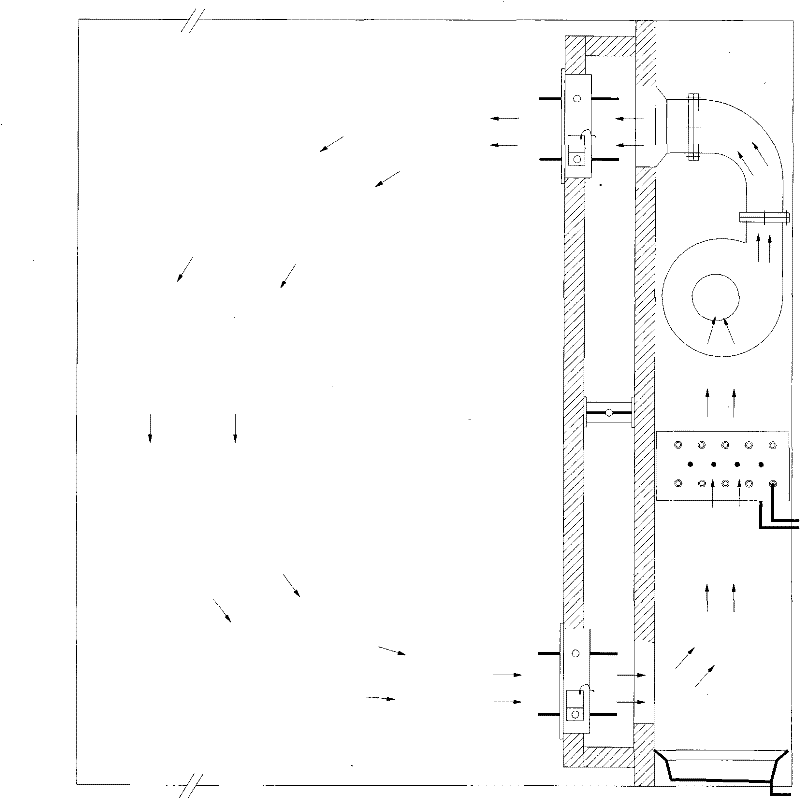

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The main parts and details of the present invention: 1. Electric air valve at the air supply port, 2. Insulation board of bypass air duct, 3. Bypass air duct, 4. Electric damper in bypass air duct, 5. Cold wall partition, 6. Back Electric air valve for tuyere, 7. Defrost water connection plate, 8. Return air outlet of cold wall partition, 9. Cold and hot air source room, 10. Defrost electric heater, 11. Evaporator, 12. Centrifugal fan, 13. Wind Tube, 14. Cold wall partition air supply outlet.

[0033] Such as figure 1 As shown, the refrigerator bypass cycle defrosting structure of the present invention is arranged at the cold wall partition 5 of the refrigerator, as figure 2As shown, the defrosting structure of the present invention includes a defrosting electric heater 10 arranged in the cold and hot air source chamber 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com