Surface Plasma Hydrophilic Modification Method of Fluorosilicone Rigid Contact Lens

A surface plasma, contact lens technology, applied in the direction of plasma, glasses/goggles, optics, etc., can solve the problems of affecting deposition, poor hydrophilicity, affecting wearing comfort of glasses, etc., to reduce deposition, hydrophilicity, etc. Improves and facilitates the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] §1, including the following steps: (1) flush the plasma processing system several times with Ar gas; (2) put the fluorosilicon contact lens into the system, and start vacuuming; (3) after the system vacuum reaches below 5Pa, pass Gas flow controller into the atmosphere, such as Ar, O 2 or N 2 , to increase the system pressure to the required pressure and stabilize it for a period of time; (4) set the required plasma treatment power; (5) set the required plasma treatment time; (6) turn on the plasma discharge power supply, and carry out surface After the processing is completed, close the intake valve, and then vacuum for a period of time.

[0031] §2. The process parameters of the plasma treatment system are as follows:

[0032] Handling Atmosphere: Ar

[0033] Plasma Frequency: 40kHz

[0034] Power size: 100W

[0035] Processing time: 120s

[0036] Atmospheric pressure: 30Pa.

Embodiment 2

[0038] Concrete processing step is identical with embodiment 1 (§1), and the technological parameter of present embodiment plasma treatment system is as follows:

[0039] Handling atmosphere: O 2

[0040] Plasma frequency: 40kHz

[0041] Power size: 100W

[0042] Processing time: 120s

[0043] Atmospheric pressure: 30Pa.

Embodiment 3

[0045] Concrete processing step is identical with embodiment 1 (§1), and the technological parameter of present embodiment plasma processing system is as follows:

[0046] Handling atmosphere: N 2

[0047] Plasma Frequency: 40kHz

[0048] Power size: 100W

[0049] Processing time: 120s

[0050] Atmospheric pressure: 30Pa.

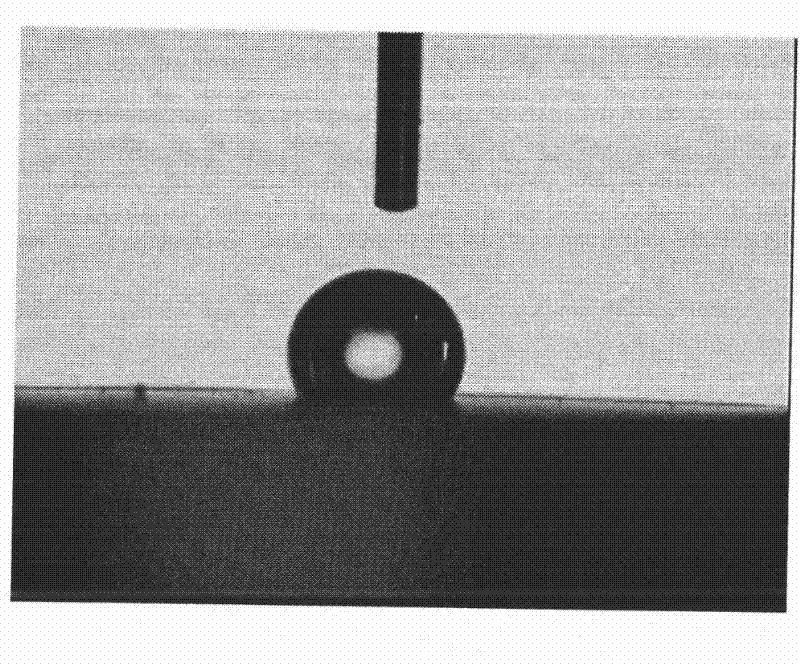

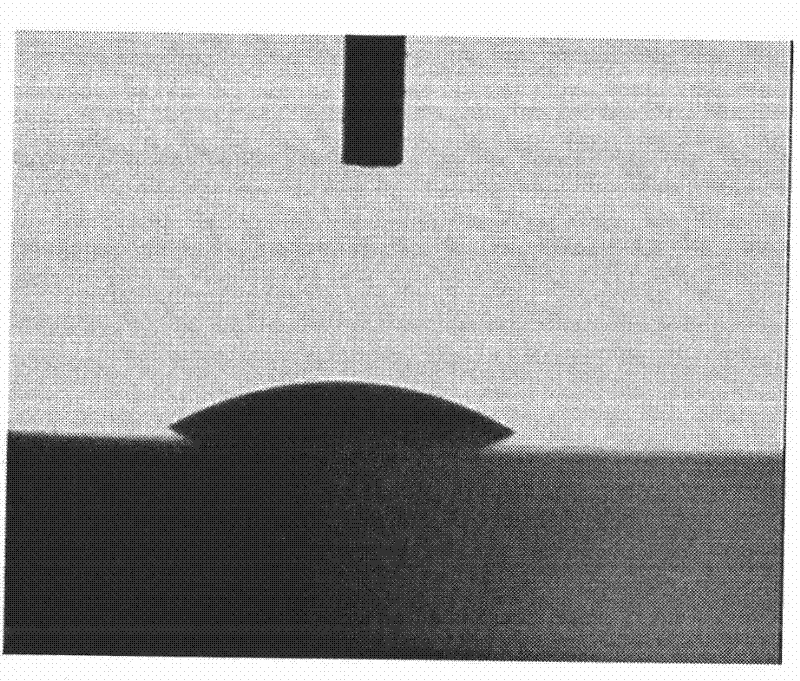

[0051] Measure the contact angle of the surface hydrophilic fluorosilicon contact lens surface that each above-mentioned implementation example makes as shown in Table 1:

[0052] Table I

[0053] Example 1 Example 2 Example 3 untreated sample Surface contact angle (°) 32 41 40 107

[0054] Through Table 1 and the attached figure 1 and attached figure 2 It can be clearly found that the contact angle of the surface of the fluorosilicon hard contact lens treated by the process of the present invention is obviously improved.

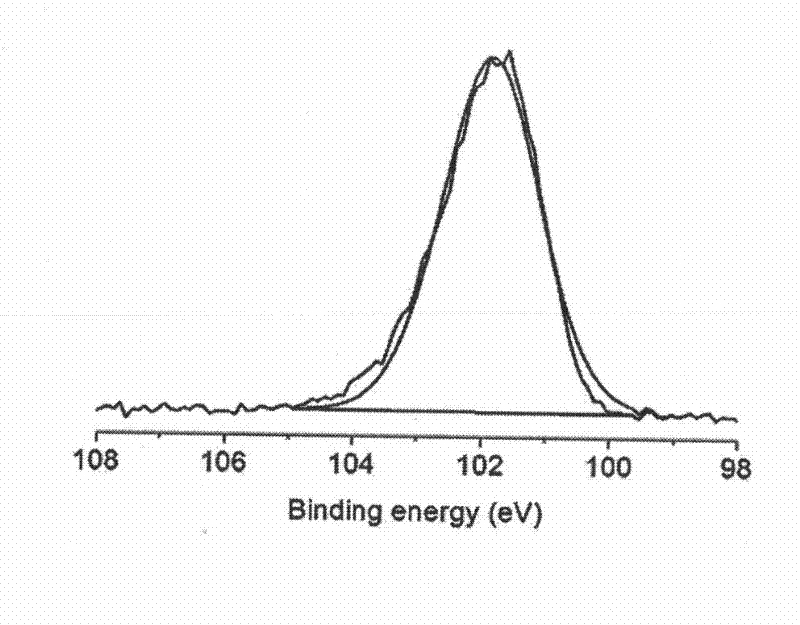

[0055] From attached image 3 And attached Figure 4 The Si2p XPS test result figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com