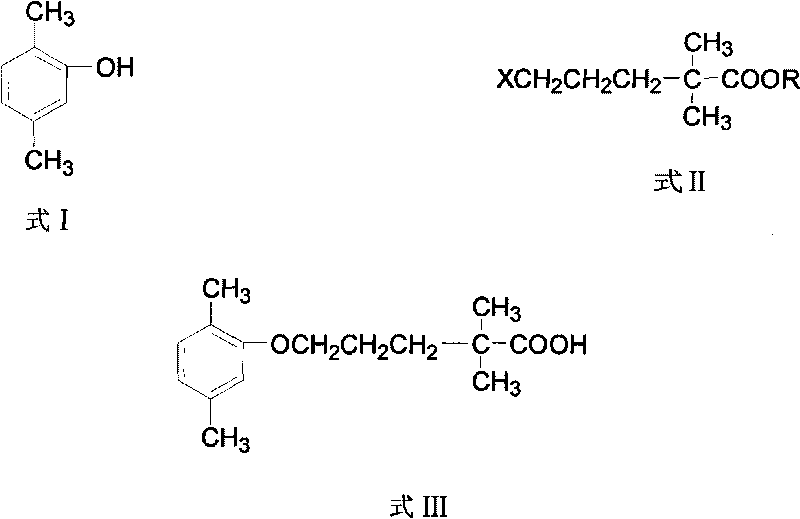

Gemfibrozil composite method

A synthetic method and the technology of gemfibrozil, which are applied in the field of preparation of the compound gemfibrozil, can solve problems such as harsh reaction conditions, expensive n-butyllithium, and dangerous operation, and achieve simple operation, cost reduction, and environmental protection. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

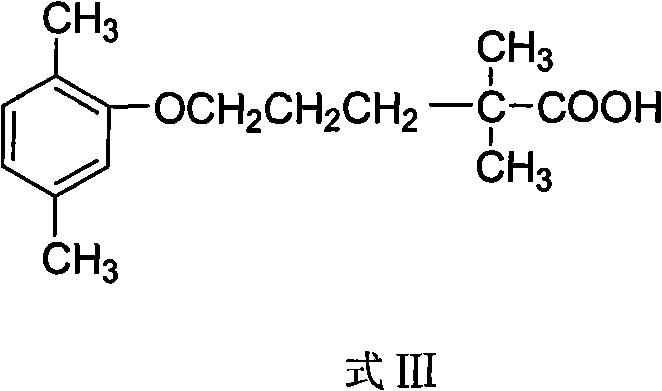

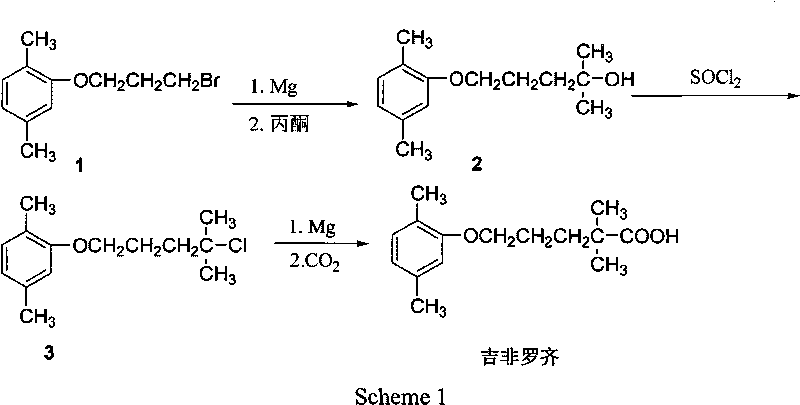

Method used

Image

Examples

Embodiment 1

[0041] In a 250mL three-necked flask, add 2,5-xylenol (15.3g, 0.125moL), tetrabutylammonium bromide (0.8g, 0.0025moL), tert-butyl 5-bromo-2,2-dimethylpentanoate Ester (37.1g, 0.14moL), sodium hydroxide (7.2g, 0.18moL) and water 40mL. After the mixture was heated to 95° C. for 10 hours, sodium hydroxide (12 g, 0.3 moL) was added to continue the reaction for 9 hours. After the reaction was complete, 200 mL of water was added and cooled to room temperature. Add concentrated hydrochloric acid to adjust pH=1~2, stir and filter to obtain a yellow solid. The solid was recrystallized from aqueous methanol to obtain 30.0 g of the product, with a yield of 90.5%, an HPLC content of 99.3%, and a melting point of 60-62°C (literature value of 61-63°C).

Embodiment 2

[0043] In a 250mL three-necked flask, add 2,5-xylenol (15.3g, 0.125moL), tetrabutylammonium bromide (0.8g, 0.0025moL), 5-chloro-2,2-dimethylpentanoic acid isopropyl Ester (30.9g, 0.15moL), sodium hydroxide (7.2g, 0.18moL) and water 40mL. After the mixture was heated to 95° C. for 10 hours, sodium hydroxide (12 g, 0.3 moL) was added to continue the reaction for 10 hours. After the reaction was complete, 200 mL of water was added and cooled to room temperature. Add concentrated hydrochloric acid to adjust pH=9~10, stir, filter, dissolve the filter cake in water, acidify with concentrated hydrochloric acid, filter, and distill the filter cake under reduced pressure to obtain product 29.3, yield 88.4%, HPLC content 99.1%, melting point 60-62 ℃.

Embodiment 3

[0045] In a 250mL three-necked flask, add 2,5-xylenol (15.3g, 0.125moL), PEG6000 (0.0025moL), 5-bromo-2,2-dimethylpentanoic acid isobutyl ester (37.1g, 0.14moL) , potassium carbonate (42.4g, 0.4moL) and water 60mL. After the mixture was heated to 100° C. for 18 hours, potassium hydroxide (16.5 g, 0.28 moL) was added to continue the reaction for 8 hours. After the reaction was complete, 200 mL of water was added and cooled to room temperature. Add concentrated hydrochloric acid to adjust pH=9~10, stir, filter, dissolve the filter cake in water, acidify with concentrated hydrochloric acid, filter, and distill the filter cake under reduced pressure to obtain product 28.3, yield 85.3%, HPLC content 99.2%, melting point 60-62 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com