Method for monitoring degree of polarization orientation and relaxation behavior of polymer with ferroelectric nanocrystalline

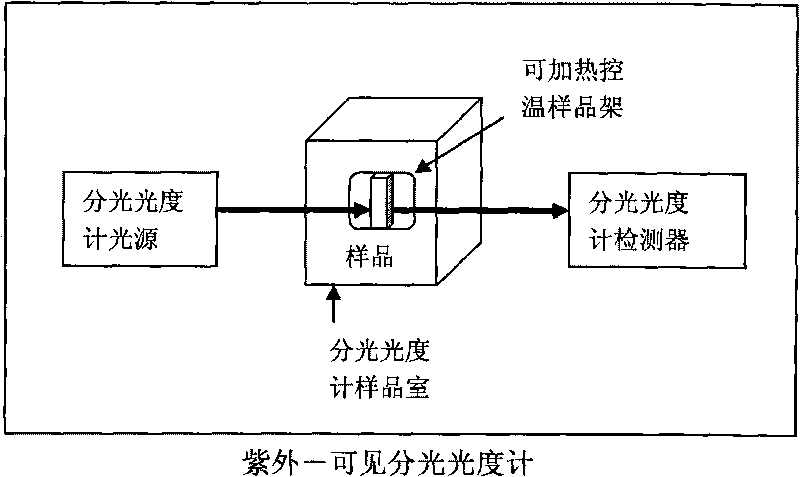

A polarization orientation, nanocrystalline technology, applied in the measurement of color/spectral characteristics, etc., can solve the problem of poor thermal stability of polarization, high detection cost, and expensive, and it can cost hundreds of thousands of yuan, or even millions of yuan, etc. problem, to achieve the effect of simple and universal instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

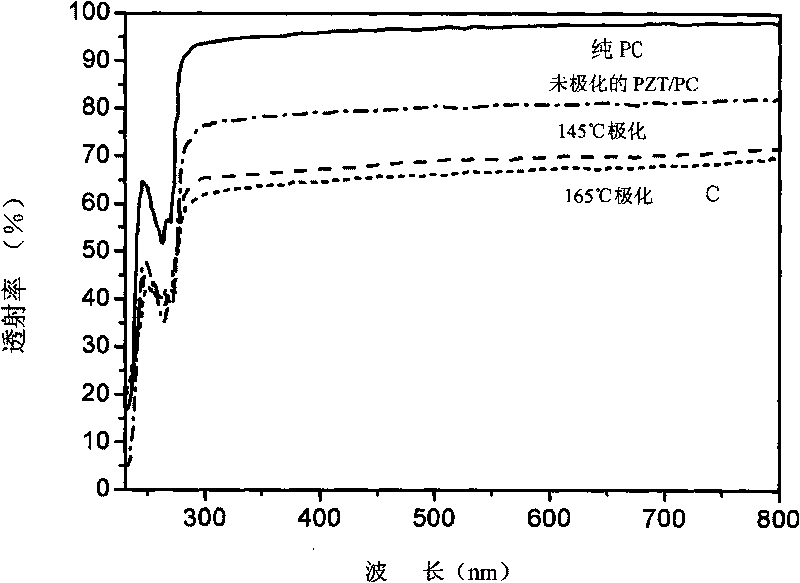

Embodiment 1

[0021] Embodiment 1: on ITO conductive glass, prepared lead zirconate titanate lead lanthanum Pb(Zr 0.52 T 0.48 )O 3 (PZT) bisphenol A polycarbonate (PC) composite polymer film sample (doping concentration is 10%, mass percent) of ferroelectric nanocrystal, namely PZT / PC sample, film thickness is at 1.2 microns (containing ferroelectric nanometer For the preparation method of electro-optic polarizable polymers containing ferroelectric nanocrystals, see Chinese Invention Patent No., ZL 200410014335.5, Electro-optic polarizable polymers containing ferroelectric nanocrystals and their preparation methods, Li Aidong, etc.). The sample was polarized near the vitrification process temperature by using the corona polarization process. The polarization conditions were as follows: the polarization temperature was 145°C and 165°C, the polarization voltage was 8000V, the polarization time was 20 minutes, and the polarization current was 5 -6μA.

Embodiment 2

[0022] Embodiment 2: on the ITO conductive glass, prepared containing (Pb 0.91 La 0.09 (Zr 0.65 Ti 0.35 ) 0.9775 o 3 , PLZT) bisphenol A polycarbonate (PC) composite polymer film sample (doping concentration is 10%, mass percent) of lead zirconate lanthanum titanate ferroelectric nanocrystal, namely PLZT / PC sample, film thickness is at 1.5 microns (See Chinese invention patent number, ZL200410014335.5). The sample was polarized at a vitrification temperature of 143°C by corona polarization technology, and the polarization conditions were: polarization voltage 8000V, polarization time 20 minutes, and polarization current 5-6μA.

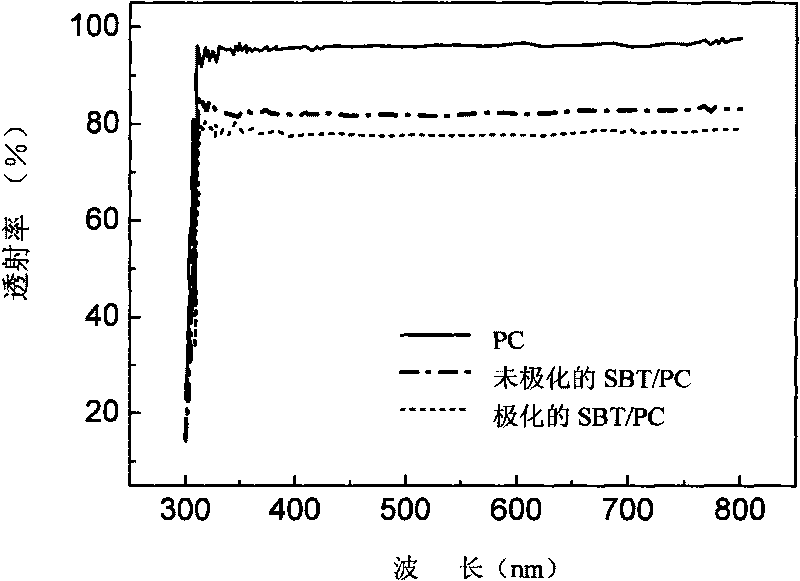

Embodiment 3

[0023] Embodiment 3: On the ITO conductive glass, prepared containing SrBi 2 Ta 2 o 9 (SBT) ferroelectric nanocrystalline bisphenol A polycarbonate (PC) composite polymer film sample (doping concentration is 10%, mass percentage), namely SBT / PC two kinds of samples, the film thickness is 1.5 microns (see China Invention patent number, ZL 200410014335.5). The sample was polarized at a vitrification temperature of 143°C by corona polarization process, and the polarization conditions were: polarization voltage 8000V, polarization time 20 minutes, and polarization current 5-6μA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electro-optic coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com