Method for bonding aluminum or aluminum alloy surface with resin material

A technology of aluminum alloy surface and resin material, which is applied in the bonding field of aluminum or aluminum alloy surface and resin material, can solve problems such as devices with complex shapes, and achieve the effects of high bonding strength, environmentally friendly formula, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The metal part to be bonded is a pure aluminum substrate with a size of 50×30×0.2 (mm), and the resin material to be bonded is low-density polyethylene (LDPE). Fast bonding is achieved through the following steps:

[0062] Step 1): Self-assemble into polymer nano film on the surface of pure aluminum substrate and LDPE surface:

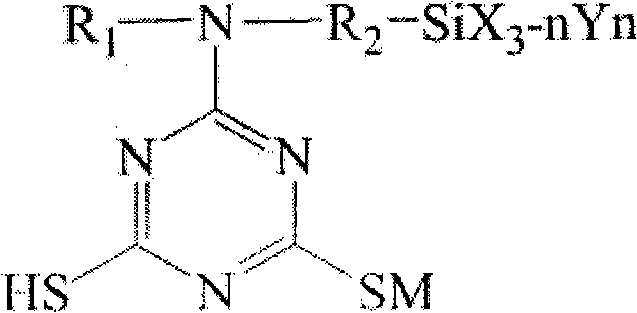

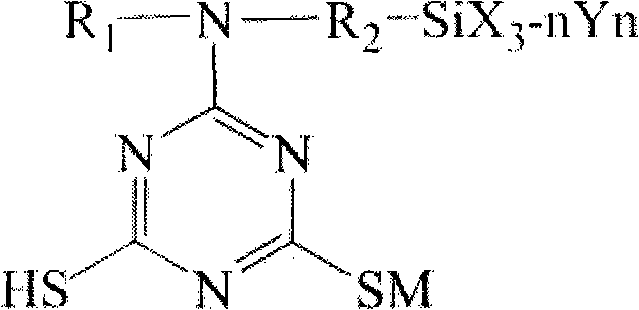

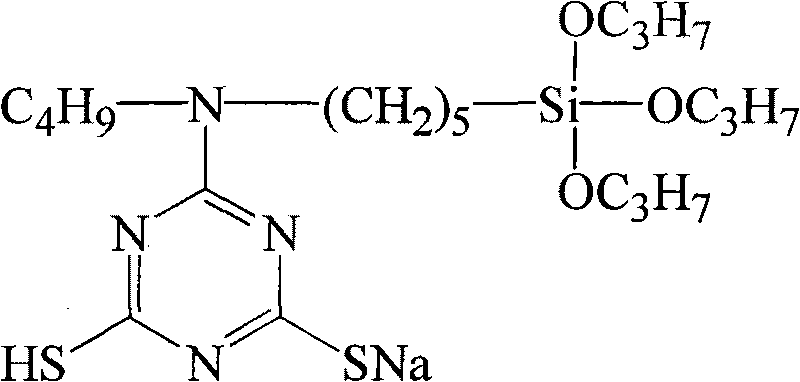

[0063] The solvent of the self-assembly solution is absolute ethanol: water=95:5 (volume ratio), and the alkoxysilane compound with reactive mercapto groups is:

[0064]

[0065] The concentration is 1.0mmol / L; the maturation time of the assembly solution is 24h;

[0066] The configuration process of the self-assembly solution is as follows: first weigh the reactive sulfhydryl alkoxysilane compound into a volumetric flask according to the concentration of the solution to be configured, and then add anhydrous ethanol at a ratio of 95:5, and then add it. Ionized water

[0067] The assembly is as follows: the material to be processed is put into the configu...

Embodiment 2

[0078] The metal part to be bonded is an aluminum-zinc alloy substrate with a size of 50×30×0.3 (mm), and the resin material to be bonded is polypropylene (PP). Fastening and bonding are achieved through the following steps:

[0079] Step 1): Pretreatment

[0080] Firstly, the aluminum-zinc alloy substrate was washed with pure acetone solvent, and polypropylene was ultrasonically washed with absolute ethanol for 20 minutes, and then dried;

[0081] Then, degrease the surface of the aluminum-zinc alloy substrate with 10% SK-144 alkaline solution at 60°C, rinse the surface with clean water and dry it;

[0082] Then, the surface of the aluminum-zinc alloy substrate and the polypropylene surface were treated by corona discharge for 20s with a low-temperature plasma power supply.

[0083] Step 2): Self-assemble into polymer nano film on the surface of aluminum-zinc alloy substrate and polypropylene surface:

[0084] The solvent of the self-assembly solution is absolute ethanol: water = 90:10,...

Embodiment 3

[0097] The metal part to be bonded is an aluminum-magnesium alloy substrate with a size of 50×30×0.3 (mm), and the resin material to be bonded is high-density polyethylene (HDPE). Fastening and bonding are achieved through the following steps:

[0098] Step 1): Pretreatment

[0099] First, the aluminum-magnesium alloy substrate was washed with pure acetone solvent, and the HDPE was ultrasonically washed with absolute ethanol for 15 minutes, and then dried;

[0100] Then, degrease the surface of the aluminum-magnesium alloy substrate with an aqueous solution of 10% SK-144 alkaline solution at 70°C, rinse the surface with clean water and dry it;

[0101] Then, the surface of the aluminum-magnesium alloy substrate and the HDPE surface were treated by corona discharge for 20s with a low-temperature plasma power supply.

[0102] Step 2): Self-assemble into polymer nano film on the surface of aluminum-magnesium alloy substrate and HDPE surface:

[0103] The solvent of the self-assembly solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com