A kind of heat-conducting adhesive and its preparation method and application

A technology of thermally conductive adhesives and thermally conductive fillers, applied in the direction of adhesive types, natural rubber adhesives, polymer adhesive additives, etc., which can solve the problems that cannot be applied to the heat dissipation of electronic appliances, the application range is limited, and the price is expensive and other issues, to achieve excellent processing performance and thermal conductivity, reduce costs, and achieve the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

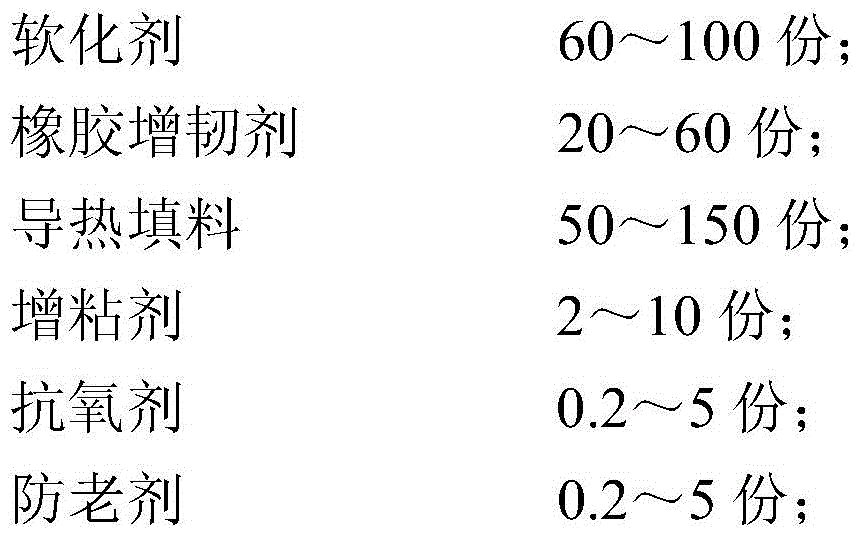

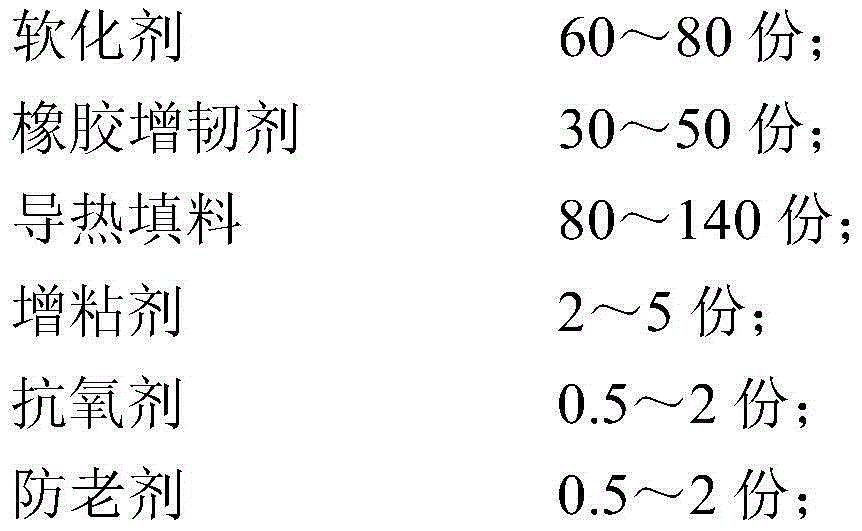

Method used

Image

Examples

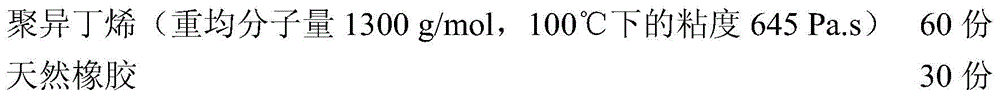

Embodiment 1

[0041] The thermally conductive adhesive contains the following components by weight:

[0042]

[0043]

[0044] (1) Dry graphite and carbon black at 150°C for 2 hours to remove water and volatile solvent impurities to obtain graphite / carbon black compound thermally conductive filler; then graphite / carbon black compound thermally conductive filler and oxidation Aluminum and ceramic powder are then compounded to obtain a mixed thermally conductive filler containing graphite and carbon black;

[0045] (2) Roll the natural rubber on the open mill, the distance between the rollers is 3 mm, and the roll time is 10 minutes; add the mixed thermally conductive filler prepared in part of the step (1) into polyisobutylene, stir evenly, and then apply it to the open mill Above the gap between the two rollers of the machine, and keep an appropriate amount of accumulated glue;

[0046](3) Coat the antioxidant 168, tackifier rosin glyceride, and anti-aging agent RD on the roller shaf...

Embodiment 2

[0048] The thermally conductive adhesive contains the following components by weight:

[0049]

[0050] (1) Dry the graphite / carbon black compound at 200°C for 1 hour to remove water and volatile solvent impurities to obtain graphite / carbon black compound thermally conductive filler; then graphite / carbon black compound thermally conductive filler and oxidation Aluminum and ceramic powder are then compounded to obtain a mixed thermally conductive filler containing graphite and carbon black;

[0051] (2) Roll the natural rubber on the open mill, the distance between the rollers is 7 mm, and the roll time is 20 minutes; add the mixed thermally conductive filler prepared in part of the step (1) into the polyisobutylene, stir evenly, and then apply it to the open mill Above the gap between the two rollers of the machine, and keep an appropriate amount of accumulated glue;

[0052] (3) Apply antioxidant 264, tackifier C5 tackifying resin, and antiaging agent DFC-34 above the rol...

Embodiment 3

[0054] The thermally conductive adhesive contains the following components by weight:

[0055]

[0056] (1) After compounding graphite / carbon black, dry it at 170°C for 1.5 hours to remove water and volatile solvent impurities to obtain graphite / carbon black compound thermally conductive filler; then graphite / carbon black compound thermally conductive filler and Zinc oxide and ceramic powder are then compounded to obtain a mixed thermally conductive filler containing graphite and carbon black;

[0057] (2) Roll the EPDM rubber on the open mill, the distance between the rollers is 3mm, and the rolling time is 15min; add the mixed thermally conductive filler prepared in part of the step (1) into the polyisobutylene, stir evenly, and then coat Go to the top of the gap between the two rollers of the mill, and keep an appropriate amount of accumulated glue;

[0058] (3) Coat the antioxidant 1010, C5 tackifying resin, rosin glyceride, and anti-aging agent RD on the roller; then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com