Method for hydrolyzing polyvinyl acetate to prepare polyvinyl alcohol in high-temperature liquid water under catalysis of organic acid

A technology of polyvinyl acetate and high-temperature liquid water is applied in the field of polyvinyl acetate hydrolysis to prepare polyvinyl alcohol under the catalysis of organic acid in high-temperature liquid water, which can solve the problems of product molecular weight drop, weak catalytic effect, long reaction time, etc. The effect of increasing reaction speed, reducing depolymerization and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

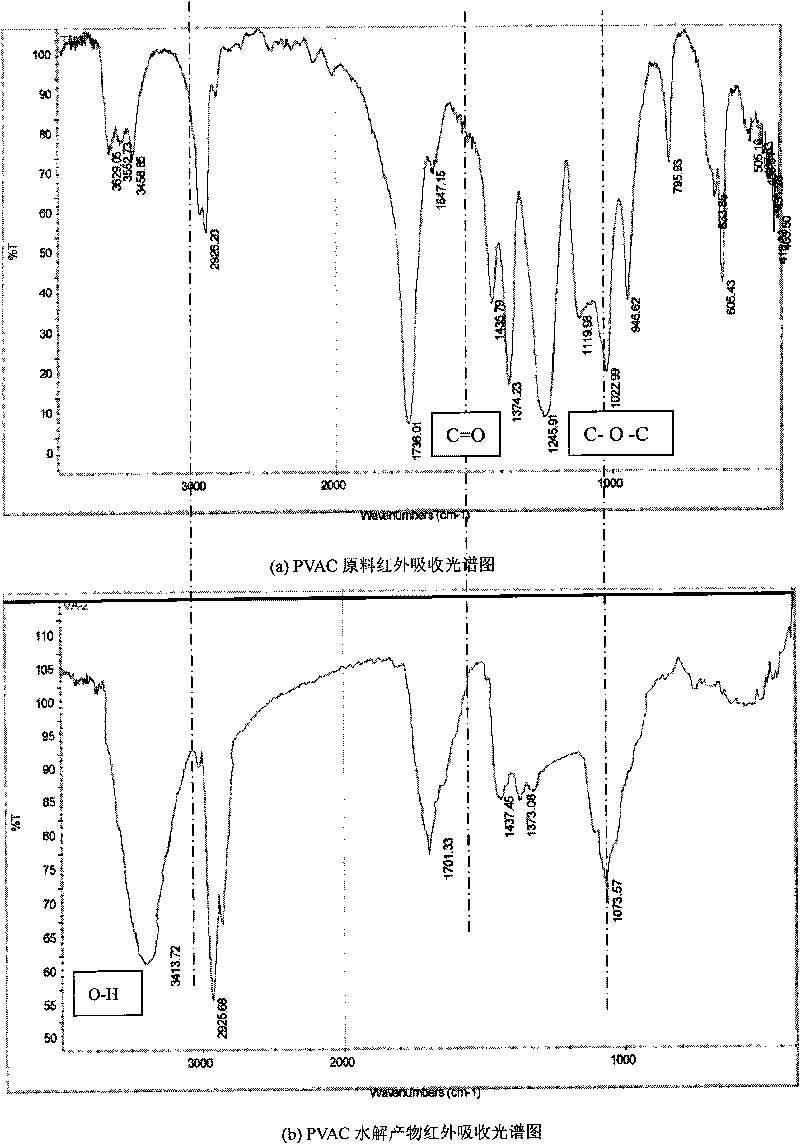

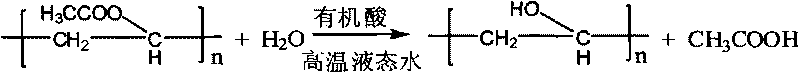

Method used

Image

Examples

Embodiment 1

[0033] Add 300g of acetic acid aqueous solution and 7.5g of polyvinyl acetate in 500mL intermittent autoclave, the mass concentration of acetic acid in the acetic acid aqueous solution is 50g / L, the weight average molecular weight of raw material polyvinyl acetate is 38,000, acetic acid aqueous solution and polyvinyl acetate The mass ratio of esters is 40:1. Start stirring, heat up to boiling under normal pressure, open the exhaust valve for 2 minutes, and use water vapor to remove the air in the kettle; heat up to 200°C for 600 minutes; , and then vacuum-dried to obtain 3.7 g of polyvinyl alcohol solid product. After analysis of the product, the degree of hydrolysis is 97.9%, the weight average molecular weight is 37,500, and the distribution width is 2.7.

Embodiment 2

[0035]Add 300g of acetic acid aqueous solution and 15g of polyvinyl acetate in a 500mL intermittent autoclave, the mass concentration of acetic acid in the acetic acid aqueous solution is 35g / L, the weight average molecular weight of raw material polyvinyl acetate is 38,000, the acetic acid aqueous solution and polyvinyl acetate The mass ratio is 20:1. Start stirring, heat up to boiling under normal pressure, open the exhaust valve for 3 minutes, and use water vapor to remove the air in the kettle; heat up to 210°C for 480 minutes; cool the hydrolyzate, release the pressure, and evaporate water and acetic acid under reduced pressure , and then vacuum-dried to obtain 7.5 g of polyvinyl alcohol solid product. After analysis of the product, the degree of hydrolysis is 98.8%, the weight average molecular weight is 36,900, and the distribution width is 2.7.

Embodiment 3

[0037] Add 300g acetic acid aqueous solution and 10g polyvinyl acetate in a 500mL intermittent high-pressure reactor, the mass concentration of acetic acid in the acetic acid aqueous solution is 45g / L, the raw material polyvinyl acetate weight average molecular weight is 38,000, acetic acid aqueous solution and polyvinyl acetate The mass ratio is 30:1. Start stirring, heat up to boiling under normal pressure, open the exhaust valve for 4 minutes, and use water vapor to remove the air in the kettle; heat up to 220°C for 340 minutes; , and then vacuum-dried to obtain 5 g of polyvinyl alcohol solid product. After analysis of the product, the degree of hydrolysis is 99%, the weight average molecular weight is 34,800, and the distribution width is 2.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com